Permanent magnet generator system with variable leakage reactance and large rotating speed range output

A permanent magnet generator, wide speed technology, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems of low reliability and complex control, achieve high reliability, small output voltage ripple, low vibration and noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

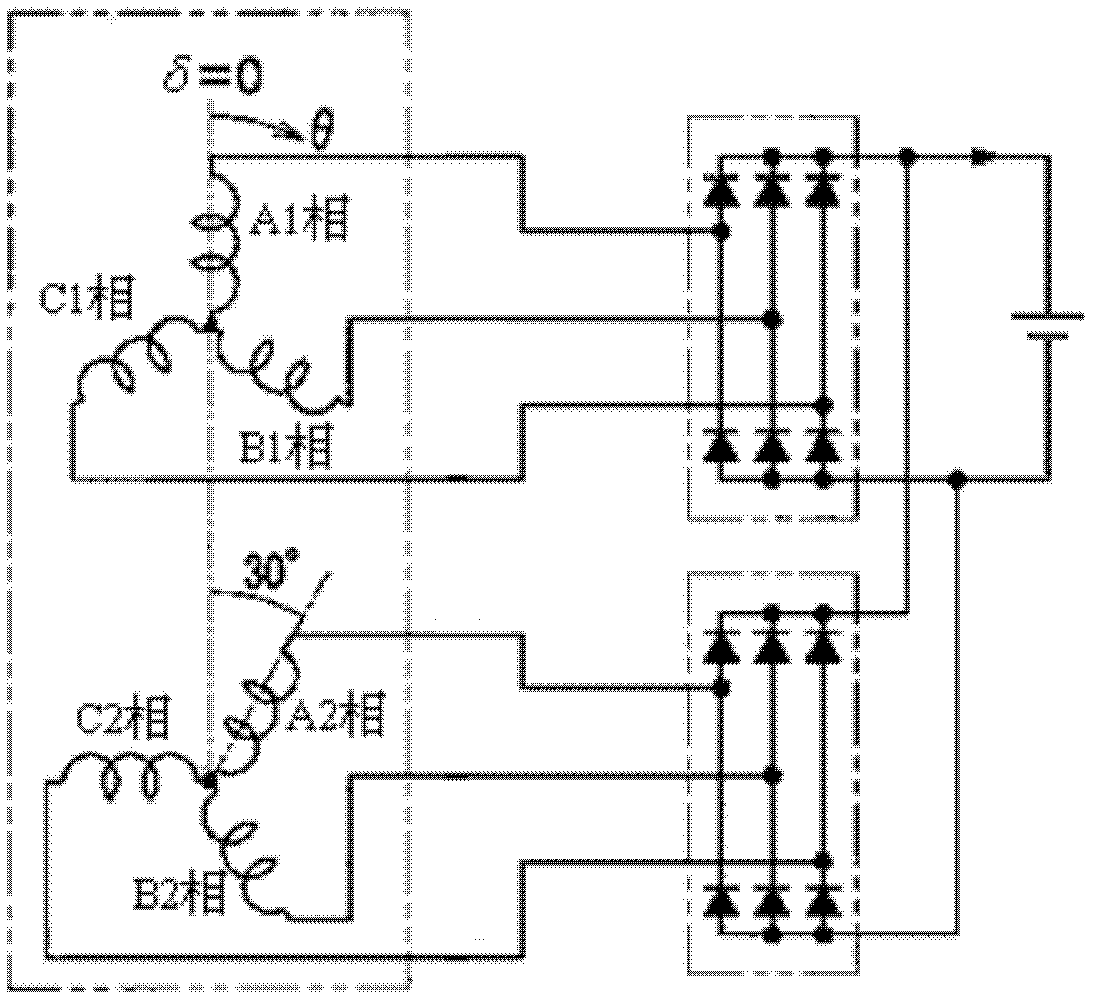

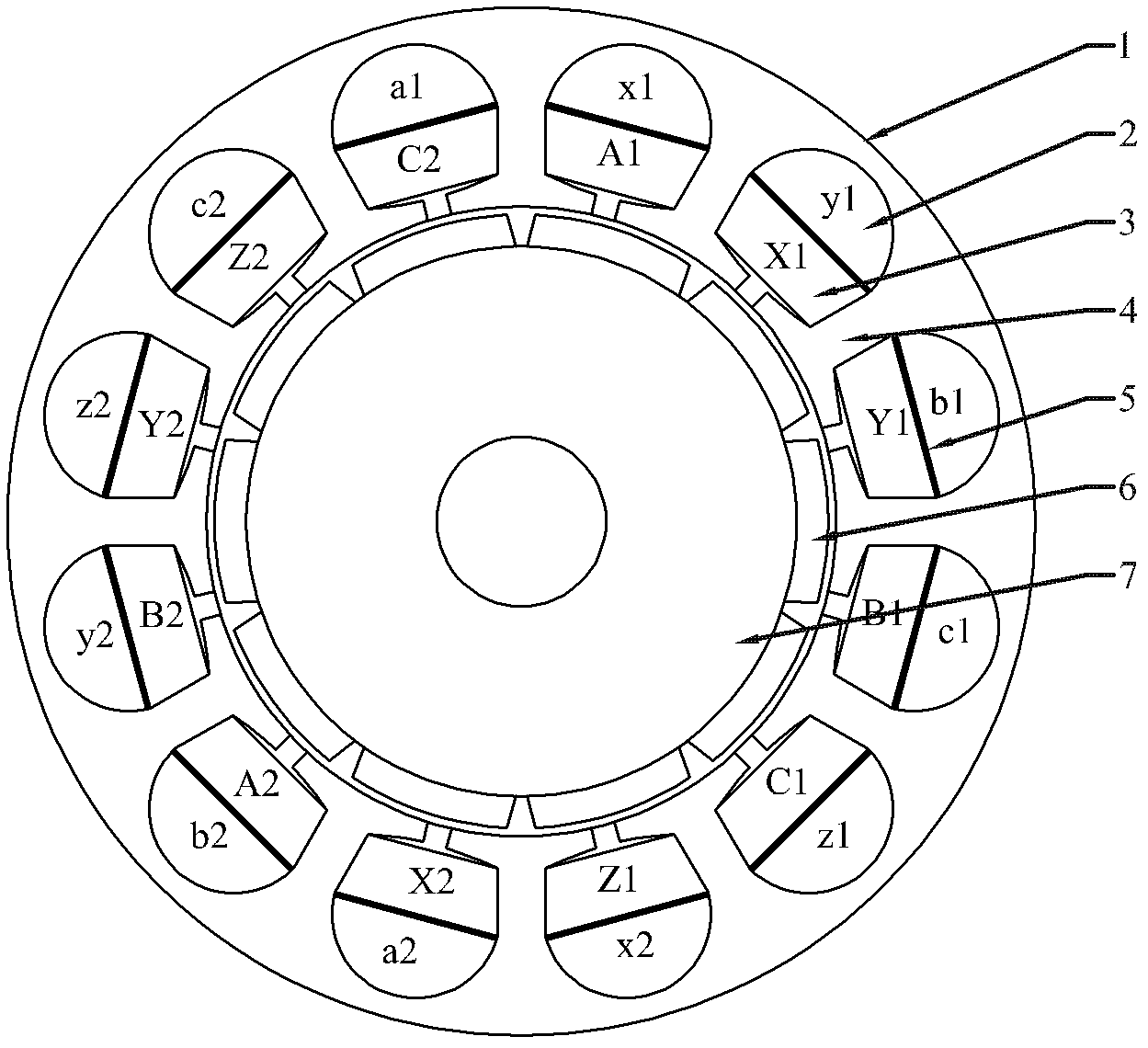

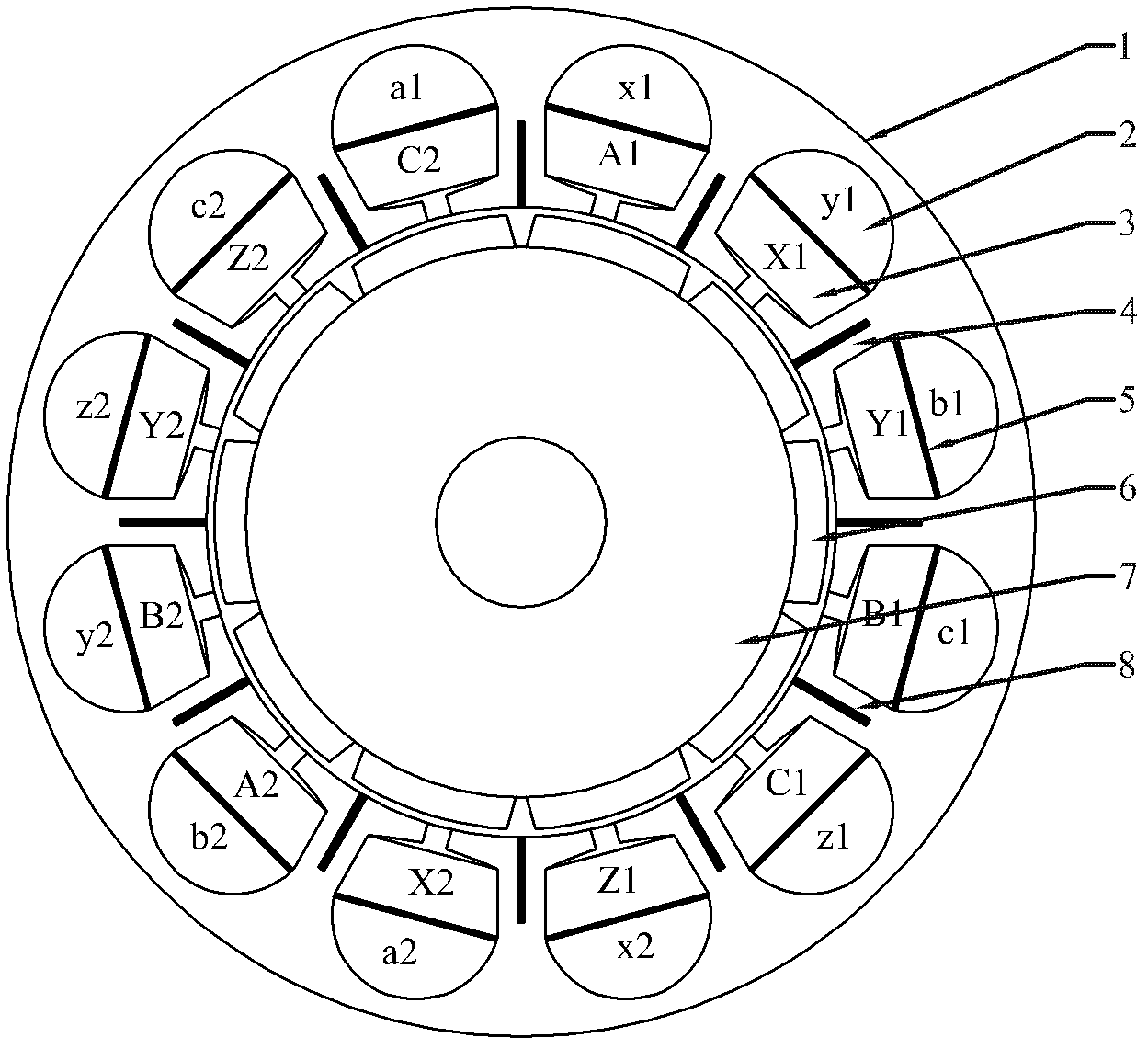

[0013] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENT 1. The leakage reactance variable wide speed range output permanent magnet generator system described in this embodiment is composed of a three-phase permanent magnet synchronous generator and two three-phase rectifiers. The three-phase permanent magnet synchronous The generator includes a stator, a rotor and an air gap. The rotor is composed of a permanent magnet 6, a rotor yoke 7 and a rotating shaft, and the number of poles of the rotor is 10n; the stator is composed of an iron core 1 and two sets of three-phase windings. The phase difference between the windings is 30° electrical angle; the number of slots of the stator core 1 is 12n, n is a positive integer, the two sets of three-phase windings are concentrated windings, and each set of three-phase windings is composed of 6n coils , the 6n coils in each set of three-phase windings are evenly distributed along the circumference and wound on the armature core teeth 4, t...

specific Embodiment approach 2

[0015] Specific Embodiment 2. This embodiment is a further limitation of the leakage reactance variable wide speed range output permanent magnet generator system described in specific embodiment 1. The leakage reactance variable wide speed range output permanent magnet generator in this embodiment The leakage reactance regulating piece 5 in the machine system is flat-shaped, and the flat leakage reactance regulating piece 5 is located in the radial middle position of the groove where it is located, and divides the groove where it is located into two parts, the axial length of which is less than The distance between the axial ends of the winding in its slot.

[0016] see figure 2 As shown, when n=1, the structural schematic diagram of the permanent magnet generator described in the present embodiment, the number of stator slots of the permanent magnet generator is 12 slots, and the number of rotor poles is 10 poles, so two adjacent stators The electrical angle difference betw...

specific Embodiment approach 3

[0017] Specific Embodiment 3. This embodiment is a further limitation of the leakage reactance variable wide speed range output permanent magnet generator system described in specific embodiment 1. The leakage reactance variable wide speed range output permanent magnet generator in this embodiment The leakage reactance regulating piece 5 in the machine system is tile-shaped, and the tile-shaped regulating piece is located in the radial middle position of the groove where it is located, and divides the groove where it is located into two parts, the axial length of which is less than The distance between the axial ends of the winding in its slot.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com