Multi-filament wide-beam electronic curtain

An electronic curtain and multi-filament technology, applied in the direction of electrical components, accelerators, etc., can solve the problem that the beam uniformity in the radiation area cannot be guaranteed, and achieve the effect of high current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

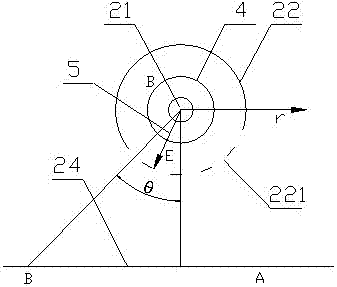

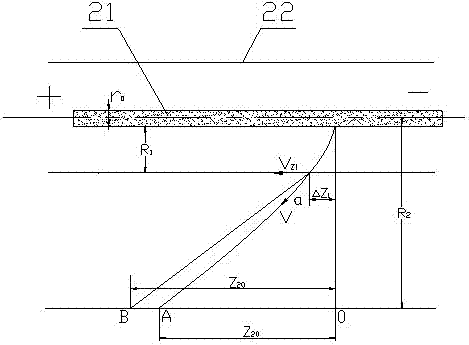

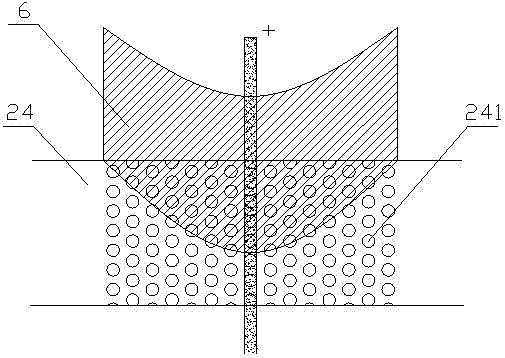

[0061] Multi-filament wide-beam electronic curtains, such as Figures 1 to 4 As shown, it includes a control system, a power supply system 1, a water cooling system, a nitrogen supply system and a vacuum system 2. The power supply system 1 includes a high-voltage power supply 11, a head power supply 12 and an isolation transformer 13. The head power supply 12 passes through a high-voltage lead-in line 14 is connected with high-voltage ceramics 15, vacuum system 2 comprises electron gun 23, outer cylinder 29, 50 filaments 21, between electron gun 23 and outer cylinder 29 is vacuum chamber 20, and the lower side of electron gun 23 is provided with the flat second The grid 24, the second grid 24 is provided with a second grid hole 241, the titanium foil 26 and the accelerating pole 25 are provided directly below the second grid 24, and 55 parallel cooling copper grids 27 are arranged on the titanium foil 26 . Multi-filament wide-beam electron curtain, the energy is 80-300keV, th...

Embodiment 2

[0076] Multi-filament wide-beam electronic curtains, such as Figures 1 to 4 As shown, it includes a control system, a power supply system 1, a water cooling system, a nitrogen supply system and a vacuum system 2. The power supply system 1 includes a high-voltage power supply 11, a head power supply 12 and an isolation transformer 13. The head power supply 12 passes through a high-voltage lead-in line 14 is connected with high-voltage ceramics 15, vacuum system 2 comprises electron gun 23, outer cylinder 29, 101 filaments 21, between electron gun 23 and outer cylinder 29 is vacuum chamber 20, and the lower side of electron gun 23 is provided with the second plate shape. The grid 24, the second grid 24 is provided with a second grid hole 241, the titanium foil 26 and the accelerating pole 25 are provided directly below the second grid 24, and 203 parallel cooling copper grids 27 are provided on the titanium foil 26 .

[0077] The length of the filament 21 is 11 cm, and the fil...

Embodiment 3

[0090] Multi-filament wide-beam electronic curtains, such as Figures 1 to 4 As shown, it includes a control system, a power supply system 1, a water cooling system, a nitrogen supply system and a vacuum system 2. The power supply system 1 includes a high-voltage power supply 11, a head power supply 12 and an isolation transformer 13. The head power supply 12 passes through a high-voltage lead-in line 14 is connected with high-voltage ceramic 15, and vacuum system 2 comprises electron gun 23, outer cylinder body 29, 135 filaments 21, is vacuum chamber 20 between electron gun 23 and outer cylinder body 29, and the lower side of electron gun 23 is provided with the second plate shape. The grid 24, the second grid 24 is provided with a second grid hole 241, the titanium foil 26 and the accelerating pole 25 are provided directly below the second grid 24, and 423 parallel cooling copper grids 27 are provided on the titanium foil 26 .

[0091] Filament 21 length is 14cm, and filame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com