Oil-removing compound and its preparation method

A compound, ionic polymer technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of reduced effect and increased dosage, and achieves the effect of low cost, strong charge affinity, and no three wastes discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The preparation method of the oil-removing compound of the present invention comprises ring-opening polymerization of dimethylamine or diethylamine and epichlorohydrin at -10-30°C and reacting for 0.5-4 hours; Linking agent, carry out cross-linking polymerization at 30-90°C, react for 3-10 hours to obtain epichlorohydrin amine cationic polymer; mix epichlorohydrin amine cationic polymer, polyacrylamide and Add the inorganic flocculant into water under stirring, and stir for 50-70 minutes to make it evenly mixed to obtain the oil-removing compound.

[0019] The preparation method of the oil removal compound of the present invention, wherein, the weight percentage of the dimethylamine or diethylamine is 45 to 70%, the weight percentage of epichlorohydrin is 30 to 50%, and the rest is a crosslinking agent; The weight percentage of the main agent epichlorohydrin amine cationic polymer is 20 to 50%, the weight percentage of polyacrylamide is 0 to 1%, the weight percentage of...

Embodiment 1

[0021] Add 200g dimethylamine (33% aqueous solution) in the reaction kettle, gradually add 200g epichlorohydrin to the reaction system under stirring, keep the temperature of the reaction system lower than 30°C, and react for 2 hours; after adding the epichlorohydrin dropwise 4.35 g of ethylenediamine was added to the reaction system, and reacted at 70° C. for 8 hours to obtain an epichlorohydrin amine cationic polymer containing 2% crosslinking agent ethylenediamine, as shown in Table 1. The obtained epichlorohydrin amine cationic polymer containing 2% cross-linking agent ethylenediamine, polyaluminum chloride, polyacrylamide and solvent distilled water are mixed in a weight ratio of 50:20:0.1:29.9, and mixed at 20-40 Stir at ℃ for 50-70 minutes to make it evenly mixed to obtain the oil-removing compound product of the present invention. Take 1mL of this product in 100mL of distilled water to make a 1% aqueous solution, take 5ml of the solution and stir in 1000ml of oily sewa...

Embodiment 2

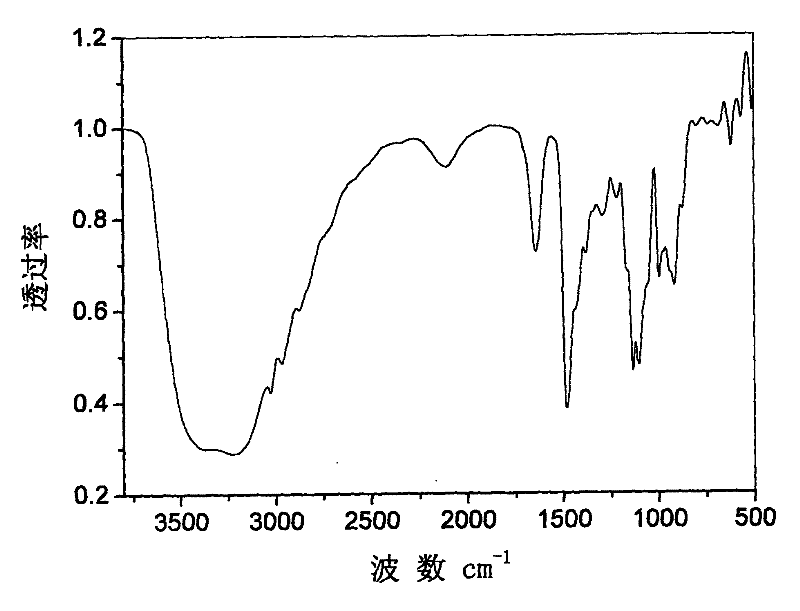

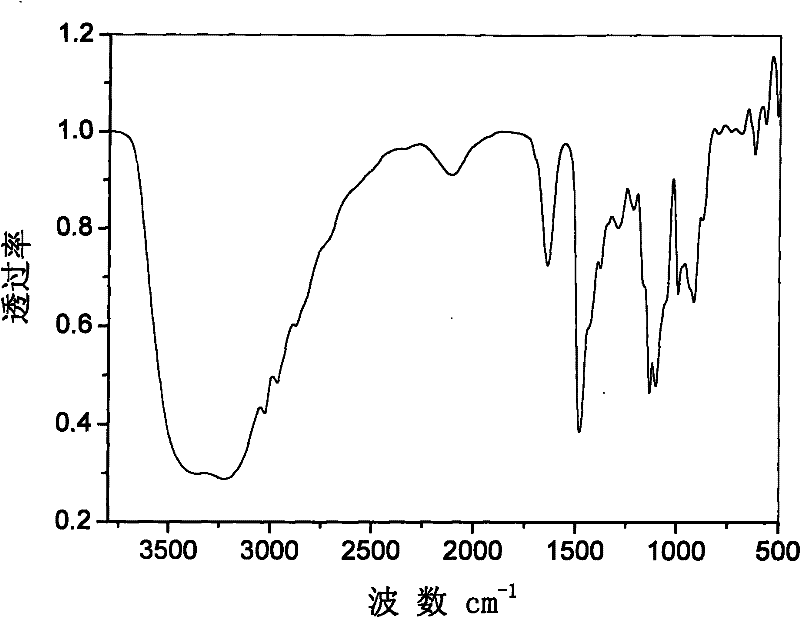

[0026] Add 200g of diethylamine to the reaction kettle, gradually add 200g of epichlorohydrin to the reaction system under stirring, keep the temperature of the reaction system below 30°C, and react for 4 hours; after adding the epichlorohydrin dropwise, add Add 5.60g diethylenetriamine, react at 90 DEG C for 6 hours, obtain the epichlorohydrin amine cationic polymer containing 1.5% crosslinking agent diethylenetriamine, as shown in Table 2, contain crosslinking agent diethylenetriamine The epichlorohydrin amine cationic polymer infrared spectrum when 1.5% is attached figure 1 shown. Mix the obtained epichlorohydrin amine cationic polymer containing 1.5% crosslinking agent diethylenetriamine, polyaluminum chloride, polyacrylamide and distilled water in a mass ratio of 50:24:0.01:25.99, and mix them at 20~ Stir at 40°C for 50-70 minutes to make it evenly mixed to obtain the oil-removing compound product of the present invention. Take 1mL of this product in 100mL of distilled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com