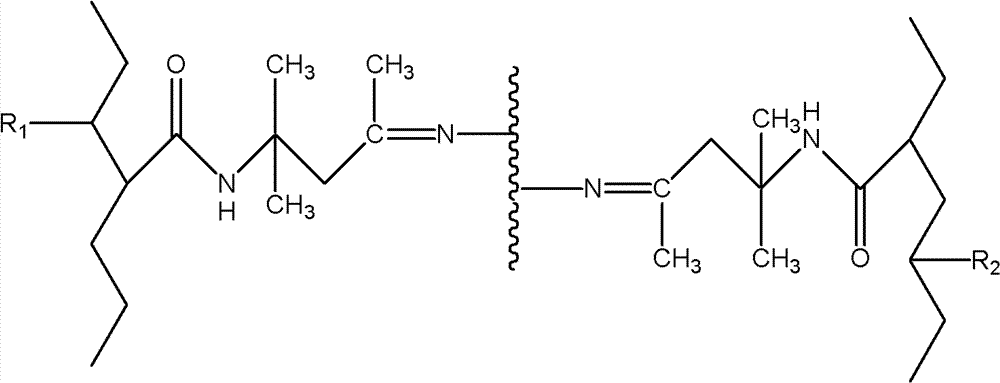

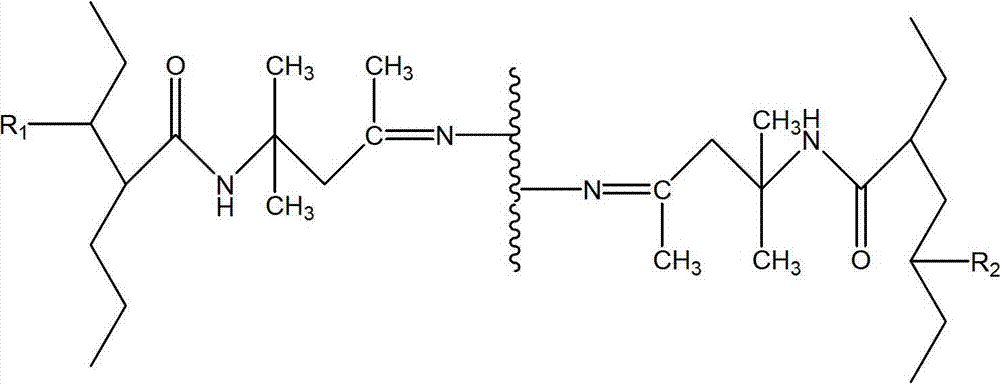

Self-crosslinking acrylic resin leather finishing agent and preparation method thereof

A technology of self-crosslinking acrylic and leather finishing agent, which is applied in leather surface treatment, small raw hide/large raw hide/leather/fur treatment, small raw hide/large raw hide/leather skin/fur chemical treatment, etc., and can solve weather resistance, Insufficient lighting performance and other problems, to achieve the effects of shortening the cross-linking curing time, good adhesion, and improving the properties of hot sticky and cold brittle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Step 1: Pre-emulsification:

[0032] First, take 40 parts by mass of deionized aqueous solution in which 2 parts of emulsifier is dissolved and add it to the first reactor equipped with a stirrer, condenser and thermometer, and raise the temperature to 35°C;

[0033] Then 36.5 parts of butyl acrylate, 12.5 parts of methyl acrylate, 1 part of acrylic acid and 0.5 part of diacetone acrylamide were mixed and added dropwise to the first reactor within 30 minutes for pre-emulsification for 30 minutes to obtain a pre-emulsion;

[0034] The second step: polymerization reaction:

[0035] Take 20 parts by mass parts of deionized aqueous solution that is dissolved with 0.5 parts of emulsifier and add in the second reactor that has agitator, condenser and thermometer, pass into sufficient amount of N 2 Remove the oxygen in the reactor and raise the temperature to 30°C;

[0036] Then add 30 parts of pre-emulsion and 10 parts of deionized aqueous solution with 0.05 parts of initia...

Embodiment 2

[0038] Step 1: Pre-emulsification:

[0039] First, take 40 parts of deionized aqueous solution dissolved with 4 parts of emulsifier in parts by mass and add it to the first reactor with agitator, condenser and thermometer, and heat up to 40°C;

[0040]Then 36.5 parts of butyl acrylate, 12.5 parts of methyl acrylate, 1 part of acrylic acid and 1 part of diacetone acrylamide were mixed and added dropwise to the first reactor within 40 minutes for pre-emulsification for 40 minutes to obtain a pre-emulsion;

[0041] The second step: polymerization reaction:

[0042] Take 20 parts by mass parts of deionized aqueous solution that is dissolved with 0.5 parts of emulsifier and add in the second reactor that has agitator, condenser and thermometer, pass into sufficient amount of N 2 Remove the oxygen in the reactor and raise the temperature to 40°C;

[0043] Then add 30 parts of pre-emulsion and 10 parts of deionized aqueous solution with 0.1 part of initiator directly into the secon...

Embodiment 3

[0045] Step 1: Pre-Emulsification:

[0046] First, take 40 parts of deionized aqueous solution dissolved with 6 parts of emulsifier in parts by mass and add it to the first reactor with agitator, condenser and thermometer, and raise the temperature to 45°C;

[0047] Then 36.5 parts of butyl acrylate, 12.5 parts of methyl acrylate, 1 part of acrylic acid and 1.5 parts of diacetone acrylamide were mixed and added dropwise to the first reactor within 60 minutes for pre-emulsification for 60 minutes to obtain a pre-emulsion;

[0048] The second step: polymerization reaction:

[0049] Take 20 parts by mass parts of deionized aqueous solution that is dissolved with 0.8 parts of emulsifier and add in the second reactor that has agitator, condenser and thermometer, pass into sufficient amount of N 2 Remove the oxygen in the reactor and raise the temperature to 36°C;

[0050] Then, 40 parts of pre-emulsion and 10 parts of deionized aqueous solution with 0.15 parts of initiator dissol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com