Preparation method for hydrolyzed silk protein paint

A technology for hydrolyzing fibroin and fibroin, which is applied in the preparation methods of peptides, protein coatings, chemical instruments and methods, etc., to achieve the effects of improving the hot stickiness and cold brittleness of resins, shortening the cross-linking curing time and soft hand feeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

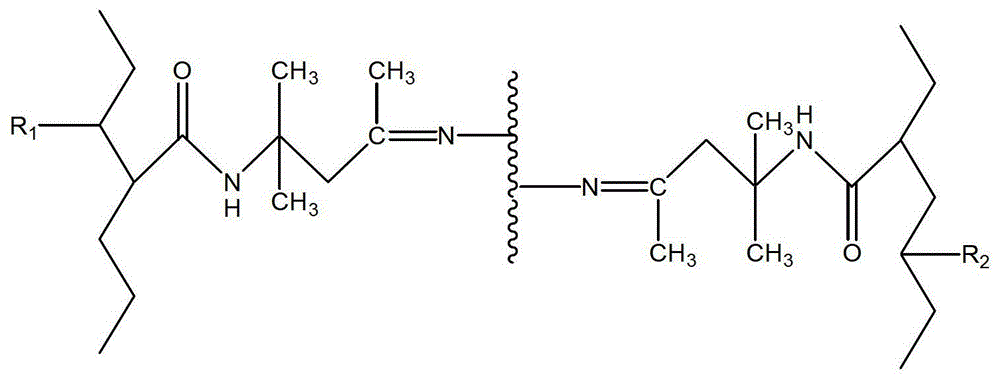

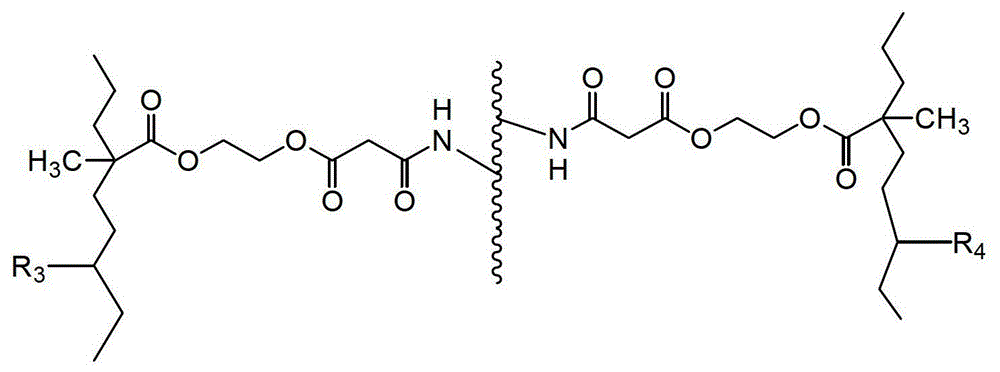

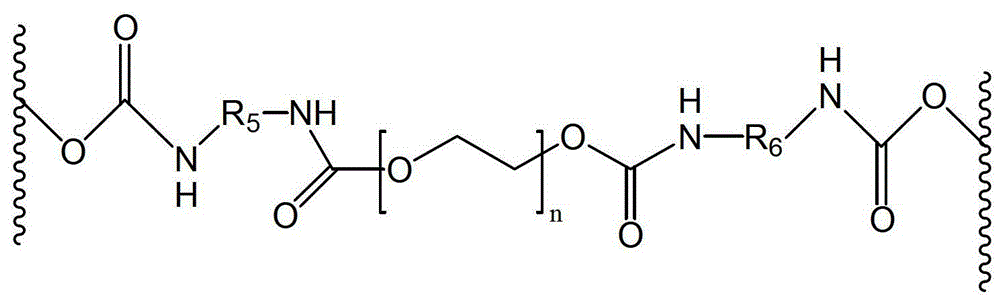

Image

Examples

Embodiment 1

[0034] A method for preparing a hydrolyzed silk protein coating, which is prepared according to the following steps by using the following raw materials and the ratio of parts by weight:

[0035] (1) Hydrolyze silk, weigh 10 parts of silk, put the weighed silk into an enamel reactor, hydrolyze silk with 5.7N azeotropic hydrochloric acid at 80°C for 5 hours, then cool to room temperature, decolorize and remove impurities , filtered, dried into powder, dissolved in deionized water to make silk protein aqueous solution. Store for later use.

[0036] (2), the preparation of acrylic resin;

[0037] a. Pre-emulsification, add 40 parts of deionized aqueous solution with 2 parts of emulsifier into the reactor with agitator, condenser and thermometer, raise the temperature to 35 ° C, add 36.5 parts of butyl acrylate, 12.5 parts of methyl acrylate After mixing 1 part of acrylic acid and 0.5 part of diacetone acrylamide or ethyl acetoacetyl methacrylate, add the mixture dropwise to the r...

Embodiment 2

[0043] A method for preparing a hydrolyzed silk protein coating, which is prepared according to the following steps by using the following raw materials and the ratio of parts by weight:

[0044] (1) Hydrolyze silk, weigh 100 parts of silkworm cocoons (after stripping off pupal lining and cocoon clothing and remove impurities), put the weighed silkworm cocoons into an enamel reactor, and heat them with 5.7N azeotropic hydrochloric acid at 180°C Hydrolyze silkworm cocoons for 50 hours, then cool to normal temperature, decolorize, remove impurities, filter, dry into powder, dissolve with deionized water to make silk protein aqueous solution. Store for later use.

[0045] (2), the preparation of acrylic resin;

[0046] a. Pre-emulsification, add 40 parts of deionized aqueous solution with 6 parts of emulsifier into the reactor with agitator, condenser and thermometer, raise the temperature to 50 ° C, add 36.5 parts of butyl acrylate, 12.5 parts of methyl acrylate After mixing 1...

Embodiment 3

[0052] A method for preparing a hydrolyzed silk protein coating, which is prepared according to the following steps by using the following raw materials and the ratio of parts by weight:

[0053] (1) Hydrolyze silk, weigh 50 parts of silk, put the weighed cocoon or silk into the enamel reactor, hydrolyze the cocoon or silk with 5.7N azeotropic hydrochloric acid at 100°C for 30 hours, then cool to room temperature, Decolorization, impurity removal, filtration, drying into powder, dissolving with deionized water to make silk protein aqueous solution. Store for later use.

[0054] (2), the preparation of acrylic resin;

[0055] a. Pre-emulsification, add 40 parts of deionized aqueous solution with 4 parts of emulsifier into the reactor with agitator, condenser and thermometer, raise the temperature to 40 ° C, add 36.5 parts of butyl acrylate, 12.5 parts of methyl acrylate After mixing 1 part of acrylic acid and 1 part of diacetone acrylamide or ethyl acetoacetyl methacrylate, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com