Acrylic emulsion for curing fibers, preparation method of acrylic emulsion, nylon polyester wadding, preparation method of nylon polyester wadding and grinding wheel

A technology of acrylic emulsion and solidified fiber, which is applied in the direction of grinding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of insufficient solvent resistance and heat resistance, achieve good wear resistance and heat resistance, and maintain aesthetics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

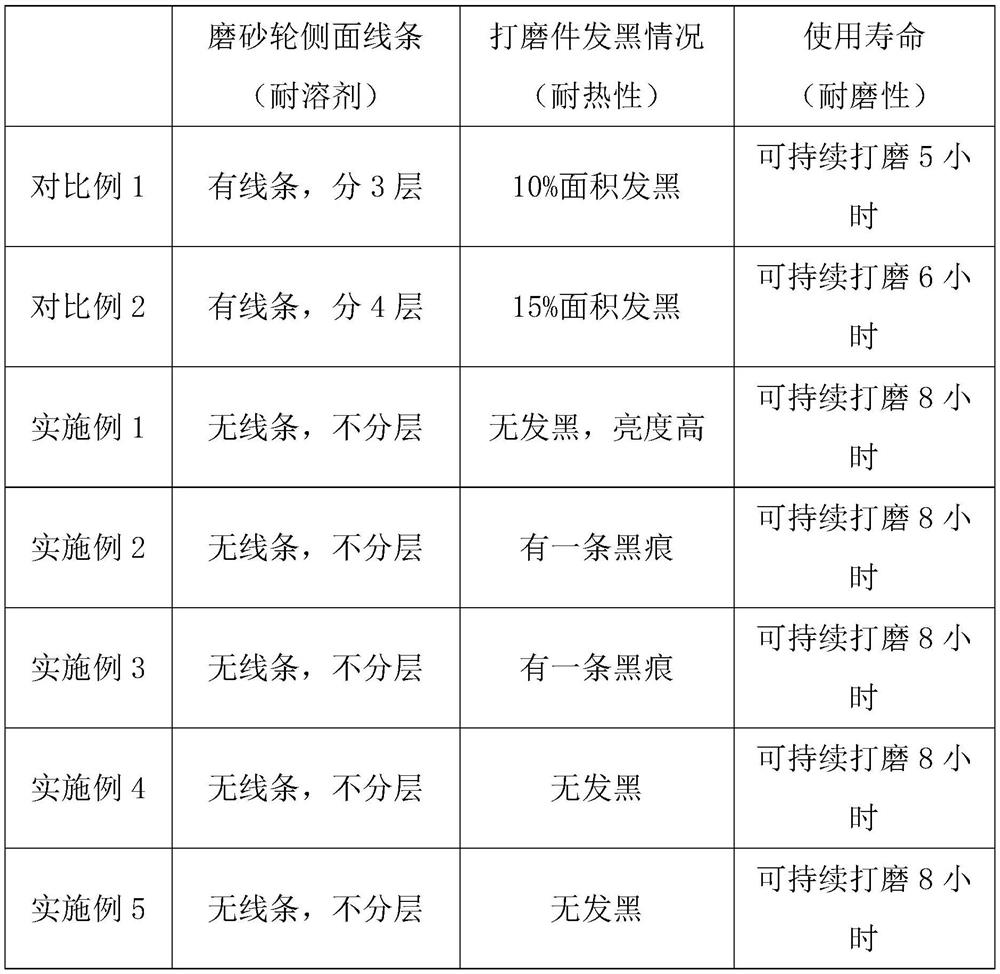

Embodiment 1

[0046] An acrylic emulsion for curing fibers, calculated in parts by weight, comprising the following components: 15 parts of butyl acrylate, 65 parts of methyl methacrylate, 15 parts of ethyl acrylate, 1.3 parts of sodium dodecylbenzenesulfonate 0.18 parts of ammonium persulfate, 0.17 parts of sodium bisulfite, 0.01 parts of ferrous sulfate, 2 parts of 3-isopropyl-dimethylbenzyl isocyanate, 0.1 parts of vinyltrimethoxysilane, 0.25 parts of buffer, 0.01 part of 2,4-diphenyl-4-methyl-1-pentene, 100 parts of deionized water.

[0047] The preparation method of the described acrylic acid emulsion that is used to solidify fiber comprises the following steps:

[0048] Step S001. Add butyl acrylate, methyl methacrylate, ethyl acrylate, 3-isopropyl-dimethylbenzyl isocyanate, vinyltrimethoxysilane, 2,4-diphenyl-4-methyl -1-Pentene, sodium dodecylbenzenesulfonate and 40 parts of deionized water are added to the emulsification tank, stirred for 1 hour to emulsify, and the emulsion A is ...

Embodiment 2

[0055] An acrylic emulsion for curing fibers, calculated in parts by weight, comprising the following components: 25 parts of butyl acrylate, 50 parts of methyl methacrylate, 15 parts of ethyl acrylate, 0.7 parts of sodium dodecylbenzenesulfonate 1 part, fatty alcohol ether sodium sulfate 1 part, ammonium persulfate 0.18 part, sodium bisulfite 0.17 part, ferrous sulfate 0.01 part, 3-isopropyl-dimethylbenzyl isocyanate 2 parts, vinyltrimethoxysilane 0.1 part, 0.25 part of buffer, 0.02 part of 2,4-diphenyl-4-methyl-1-pentene, 100 parts of deionized water.

[0056] The preparation method of the described acrylic acid emulsion that is used to solidify fiber comprises the following steps:

[0057] Step S001. Add butyl acrylate, methyl methacrylate, ethyl acrylate, 3-isopropyl-dimethylbenzyl isocyanate, vinyltrimethoxysilane, 2,4-diphenyl-4-methyl - Add 1-pentene, sodium dodecylbenzenesulfonate, sodium fatty alcohol ether sulfate and 40 parts of deionized water into the emulsificat...

Embodiment 3

[0064] An acrylic emulsion for curing fibers, calculated in parts by weight, comprising the following components: 25 parts of butyl acrylate, 50 parts of methyl methacrylate, 15 parts of ethyl acrylate, 0.7 parts of sodium lauryl sulfate, 1.3 parts of decylpolyoxyethylene(6) ether ester disodium sulfosuccinate, 0.18 parts of sodium persulfate, 0.17 parts of sodium pyrosulfite, 0.01 parts of ferrous sulfate, 1 part of 3-isopropyl-dimethylbenzyl isocyanate , 0.5 parts of vinyltrimethoxysilane, 0.2 parts of a buffer, 0.03 parts of 2,4-diphenyl-4-methyl-1-pentene, and 100 parts of deionized water.

[0065] The preparation method of the described acrylic acid emulsion that is used to solidify fiber comprises the following steps:

[0066] Step S001. Add butyl acrylate, methyl methacrylate, ethyl acrylate, 3-isopropyl-dimethylbenzyl isocyanate, vinyltrimethoxysilane, 2,4-diphenyl-4-methyl -1-Pentene, sodium lauryl sulfate, decylpolyoxyethylene (6) ether ester disodium sulfosuccinate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com