Microarc oxidation solution of titanium alloy wear-resistant coating and application thereof

A technology of micro-arc oxidation and wear-resistant coating, which is applied in the direction of coating, surface reaction electrolytic coating, electrolytic coating, etc., can solve the problems of low conductivity of the solution, low efficiency of the film layer, slow oxidation speed, etc., and achieve improvement Micro-arc discharge characteristics, improved growth efficiency, and low cost effects

Inactive Publication Date: 2011-09-28

UNIV OF SHANGHAI FOR SCI & TECH

View PDF8 Cites 26 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This method belongs to the category of anodic oxidation, the voltage used is low, the conductivity of the solution is not high, so the oxidation speed is slow, and the efficiency of film formation is low

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0030] A kind of micro-arc oxidation solution for titanium alloy wear-resistant coating, that is, KOH: 3g / L, Na 2 SiO 3 :5g / L, NaF: 3g / L, triethanolamine: 3g / L, Na 2 B 4 O 7 : 1g / L, make a solution with deionized water and stir evenly.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Login to View More

Abstract

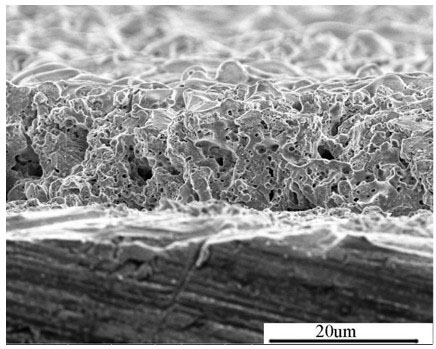

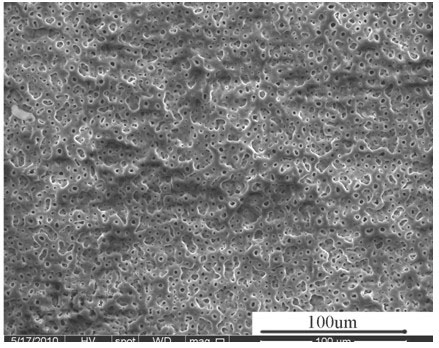

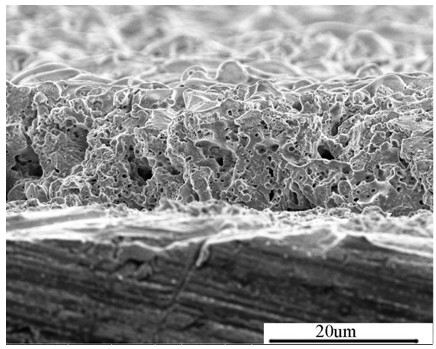

The invention discloses a microarc oxidation solution of a titanium alloy wear-resistant coating and application thereof. The microarc oxidation solution comprises solutes and a solvent, wherein the solutes are KOH, Na2SiO3, NaF, triethanolamine and Na2B407, and the solvent is deionized water. The microarc oxidation solution of the titanium alloy wear-resistant coating is used for carrying out the microarc oxidation on the surface of a titanium alloy sample so as to obtain the titanium alloy with the wear-resistant coating, i.e. the application comprises four steps of: the preparation of the microarc oxidation solution of the titanium alloy wear-resistant coating, the oil removing and washing of the surface of the titanium alloy sample, the microarc oxidation, and the washing and drying of the surface of the titanium alloy subjected to microarc oxidation. The microarc oxidation solution of the titanium alloy wear-resistant coating forms films quickly at higher voltage and current, thereby obviously improving the growth efficiency of an oxidation film; the wear-resistant coating formed after the microarc oxidation has high hardness of more than HV700; and the technology is superiorto the traditional microarc oxidation technology in terms of the growth efficiency of the coating and the hardness and abrasive resistance of the coating.

Description

Technical field [0001] The invention relates to a micro-arc oxidation solution for a titanium alloy wear-resistant coating and a method for applying the micro-arc oxidation to the surface of the titanium alloy to obtain the wear-resistant coating. Background technique [0002] Titanium and titanium alloys have high specific strength, excellent corrosion resistance, good high temperature performance, etc., and are emerging structural and functional materials. At present, it is mainly used in the fields of aerospace, navigation, petroleum, chemical industry, light industry, metallurgy, automobile, construction and medicine. However, the common disadvantages of titanium alloys are low hardness and poor wear resistance. The hardness of pure titanium is about 150~200Hv, and the titanium alloy usually does not exceed 350Hv. Such hardness values cannot meet the requirements of actual production applications in many cases. There are two ways to improve the wear resistance of titaniu...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C25D11/26

Inventor 马凤仓刘平李伟刘新宽陈小红何代华杨丽红曹雪

Owner UNIV OF SHANGHAI FOR SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com