Liquid level linear measurement method based on impedance measurement

A linear measurement and impedance measurement technology, applied in the field of sensing measurement, can solve the problems of easy inaccuracy, complex structure, high water quality requirements, and achieve the requirements of simplifying the production process, broad market prospects, and high measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

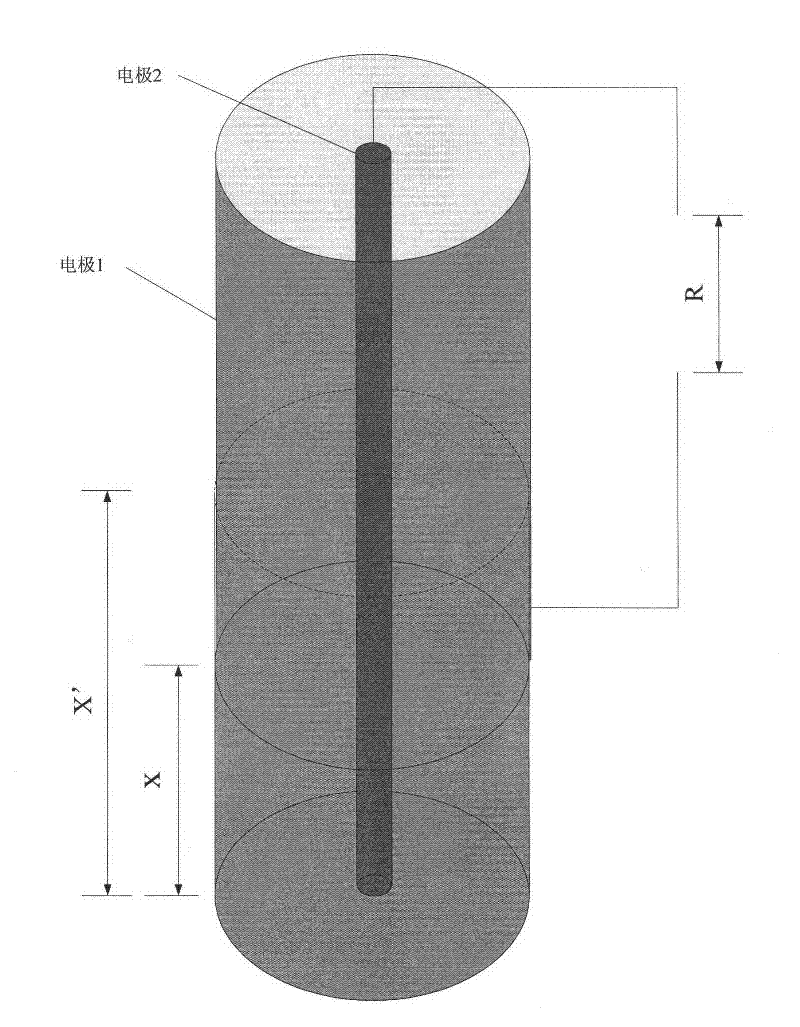

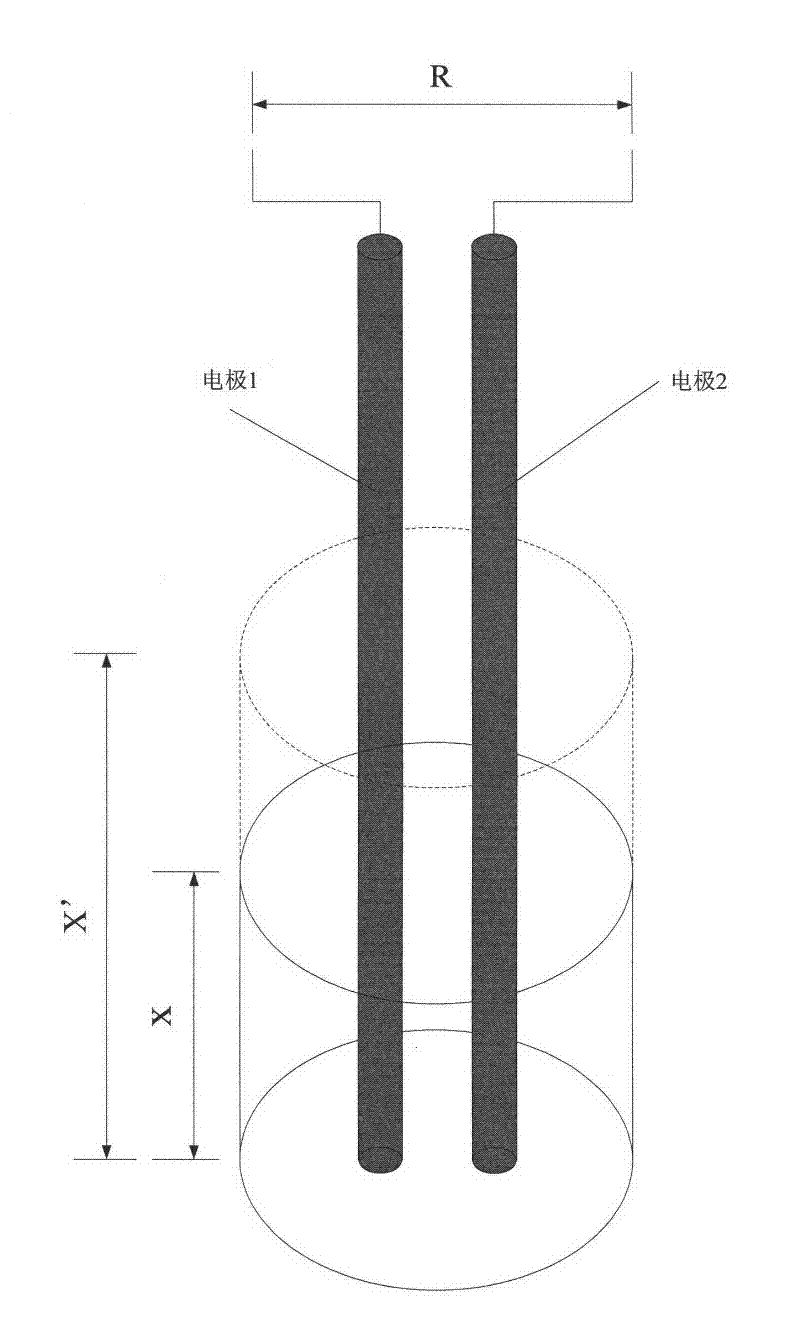

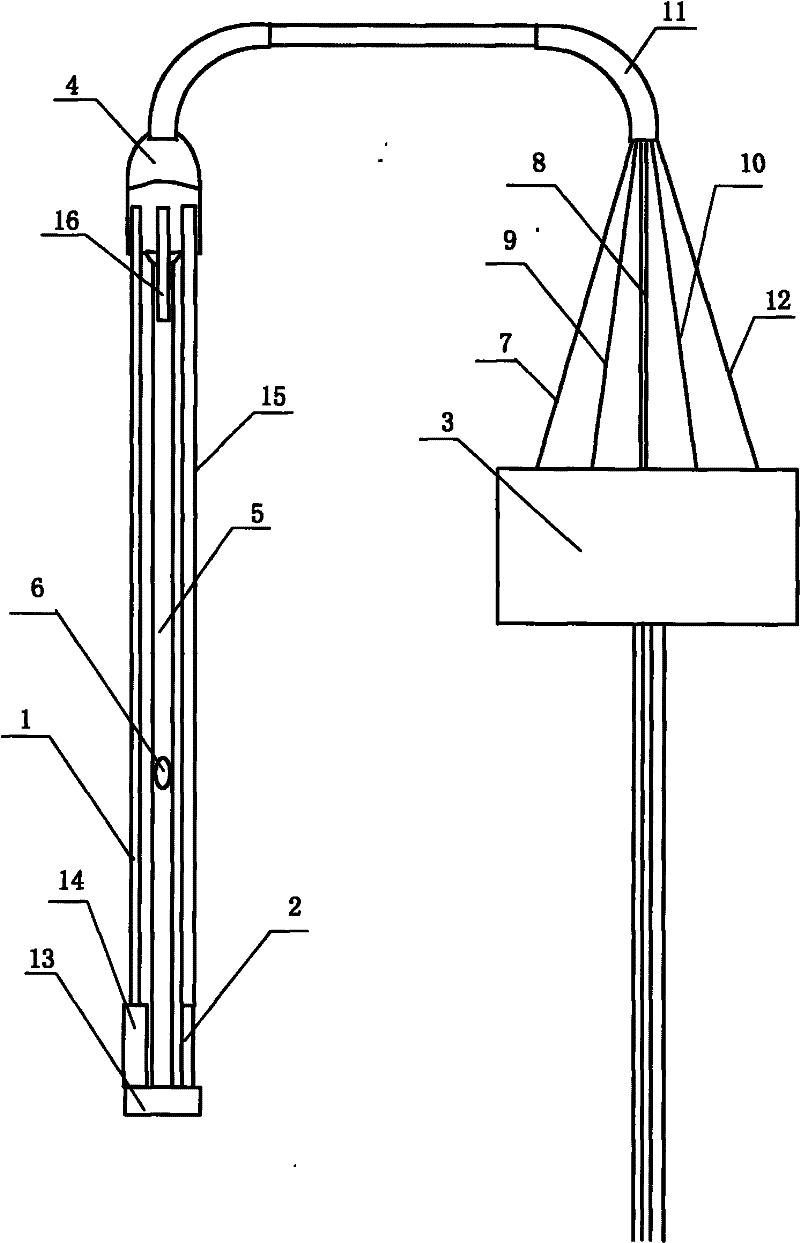

[0011] The invention discloses a liquid level linear measurement method based on impedance measurement, which comprises the following steps: measuring the liquid impedance with measuring electrodes, introducing a group of reference electrodes, and using the liquid impedance and the parallel or coaxial measuring electrodes to immerse the depth of the liquid The relationship is inversely proportional. The impedance measured by the reference electrode is divided by the liquid impedance measured by the measuring electrode. After AD collection, it is calculated by MCU and DSP digital chips. On the one hand, the final liquid impedance output by the measuring electrode is related to the liquid depth of the liquid, and has nothing to do with the composition of the liquid. On the other hand, the original measured liquid impedance is related to the measurement electrode immersion The reciprocal mathematical relationship of the liquid depth is converted into a linear relationship between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com