Producing method of overlay ceramic electronic component

A manufacturing method and technology of electronic components, applied in fixed capacitor parts, laminated capacitors, fixed capacitor electrodes, etc., can solve problems such as poor short circuit, erosion, and reduced coverage of internal electrodes, and achieve high reliability and coverage High, no bad effect of short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] [1] Production of multilayer ceramic capacitors (sample No. 1 in Table 1) according to Examples of the present invention

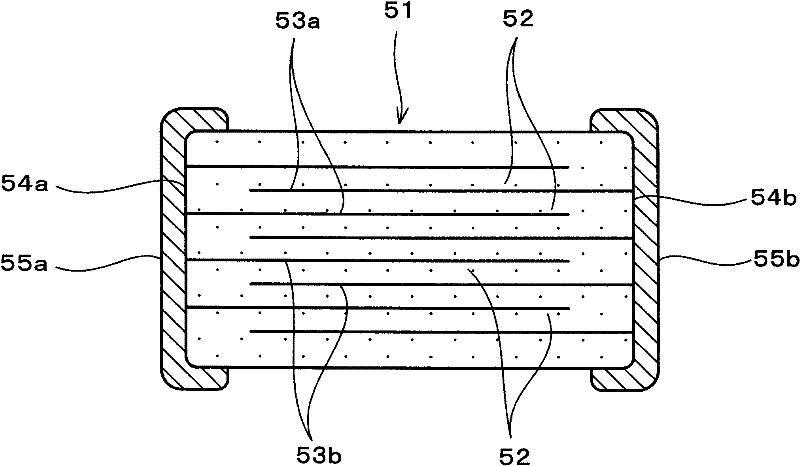

[0062] In this Example 1, a typical laminated ceramic electronic part having figure 1 The case of a multilayer ceramic capacitor having the structure shown will be described as an example.

[0063] Such as figure 1 As shown, this multilayer ceramic capacitor has a structure in which, in a multilayer ceramic element (capacitor element) 51, a plurality of internal electrodes 53a, 53b are stacked with a ceramic layer 52 interposed therebetween, and the internal electrodes 53a, 53b facing each other with the ceramic layer 52 interposed therebetween 53b is drawn out alternately to end surfaces 54a, 54b on different sides of multilayer ceramic element 51, and is connected to external electrodes 55a, 55b formed on the end surfaces.

[0064] (1-1) Production of internal electrode paste

[0065] As a conductive component constituting the internal electrod...

Embodiment 2

[0145] In this second example, the first internal electrode pattern is formed on the substrate (support film), and the first dielectric green sheet (ceramic green sheet), the second internal electrode pattern, and the second dielectric green sheet are sequentially stacked thereon. sheets (ceramic green sheets) to form a multilayer structural unit, and a multilayer ceramic capacitor is produced by laminating a predetermined number of the multilayer structural units. In addition, in the case of this Example 2, similarly to the case of the above-mentioned Example 1, a figure 1 Multilayer ceramic capacitors of the configuration shown. It will be explained below.

[0146] In this Example 2,

[0147] As (a) a ceramic slurry for forming a dielectric green sheet, and

[0148] (b) an internal electrode paste for forming an internal electrode pattern,

[0149] The same materials as those used in Example 1 above were used.

[0150] First, if Figure 4 As shown, the internal electro...

Embodiment 3

[0164] In this Example 3, as Image 6 As shown in FIG. The dielectric paste for the stepped absorption layer was dried at 60° C. for 5 minutes to form the dielectric pattern for the stepped absorption layer (stepped absorption layer) 20 , and a multilayer ceramic capacitor was produced in the same manner as the multilayer ceramic capacitor of Example 1.

[0165] In addition, in Image 6 , labeled with figure 2 Parts with the same symbols represent the same or corresponding parts.

[0166] For the multilayer ceramic capacitor of Example 3, the coverage of internal electrodes, electrical characteristic defect rate (short circuit defect rate), and structural defect occurrence rate were inspected by the same method as in the case of Example 1 above. As a result, similar to the case of the sample No. 1 in Table 1 of Example 1 (the sample related to the example of the present invention), it was confirmed that a high coverage of the internal electrodes and a high electrical chara...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com