Low-heat-resistance packaging structure of power MOS (Metal Oxide Semiconductor) device

A technology of MOS device and packaging structure, which is applied to electric solid-state devices, semiconductor devices, semiconductor/solid-state device components, etc. Form differences and other issues, to achieve the effect of reducing body inductance, reducing thermal resistance, and reducing thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

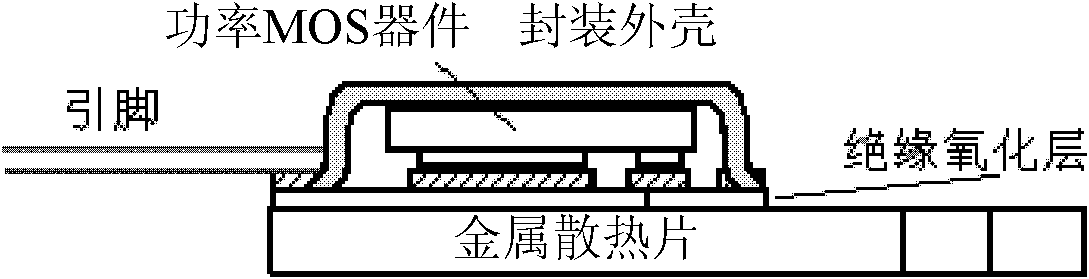

[0019] A low thermal resistance package structure for power MOS devices, such as image 3 As shown, it includes a power MOS device, a metal heat sink, a package shell, and external pins for the gate, source and drain. The surface of the metal heat sink has a thin layer of insulating oxide; the surface of the thin layer of insulating oxide has gate, source and drain metal pads corresponding to the gate, source and drain of the power MOS device, respectively; and the power MOS device Flip-chip on the thin insulating oxide surface of the metal heat sink; the gate, source and drain of the power MOS device are respectively welded to the gate, source and drain metal pads on the thin insulating oxide surface; thin The gate, source, and drain metal pads on the surface of the insulating oxide layer are connected to the external pins of the gate, source, and drain respectively; the package shell is installed outside the power MOS device to realize the isolation of the power MOS device fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com