System for combined cycle mechanical drive in cryogenic liquefaction processes

A component and expander technology, applied in liquefaction, refrigeration and liquefaction, solidification, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

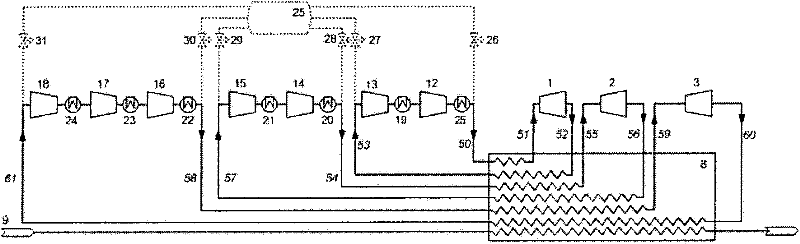

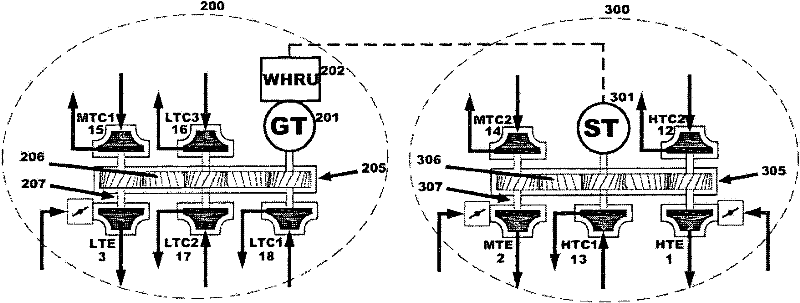

[0014] Such as figure 1 As shown, this refrigeration assembly includes three different refrigeration circuits:

[0015] The high-temperature circuit, shown here with two compressors 12 , 13 or compressor stages and one expander 1 or expander stage, only the compressor and expander respectively are labeled in the following. This is the base case for all three circuits, but if the process advantage is evident, the layout can be made with a different number of compressor or expander units, depending on process requirements or other criteria. This high temperature circuit is used for overheating cooling.

[0016] An intermediate temperature circuit is used to condense the LNG, and this circuit usually consists of two compressors 14, 15 and an expander 2; and

[0017] In the basic case, the cryogenic circuit likewise consists of three compressors 16 , 17 , 18 and an expander and is used for subcooling the LNG.

[0018] Further information on this refrigeration assembly is found ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com