Adverse current closed type multistage seawater desalination system and method

A seawater, closed technology, applied in chemical instruments and methods, seawater treatment, general water supply conservation, etc., can solve problems such as limiting the effect of heat and mass exchange between air and seawater, improve water production and water production efficiency, and achieve heat capacity. Matching, optimal heat effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

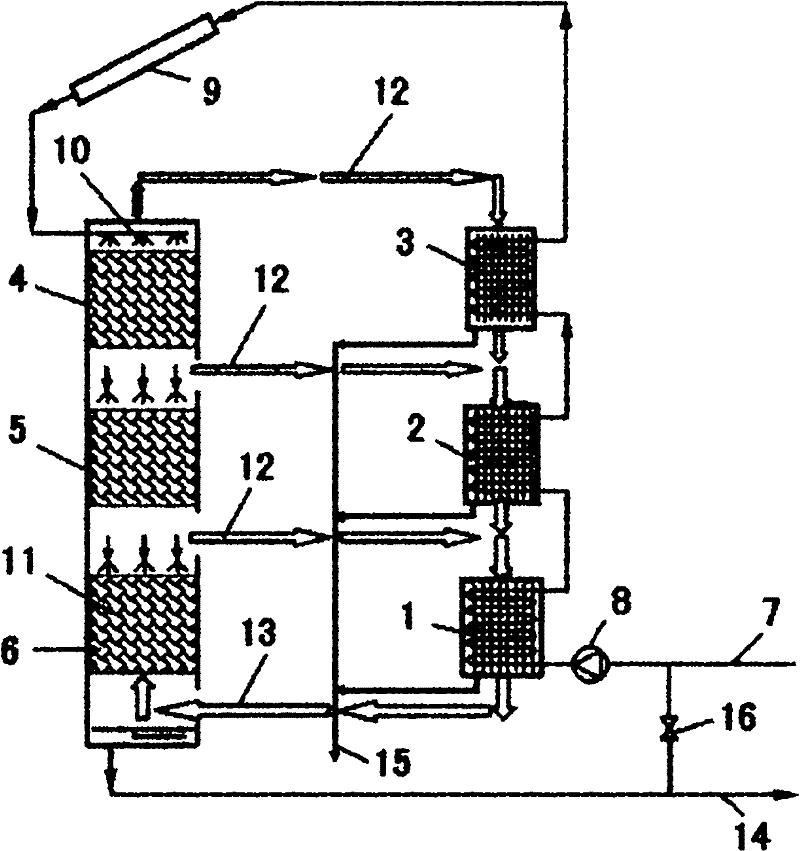

[0023] Such as figure 1 As shown, this embodiment includes a first-stage heat exchanger 1, a second-stage heat exchanger 2, and a third-stage heat exchanger 3, as well as a first-stage spray tower 4, a second-stage spray tower 5, and a third-stage heat exchanger. Level spray tower 6. The heat exchange tubes of the three-stage heat exchangers 1, 2, and 3 are connected in series, and the inlet of the heat exchange tubes of the first-stage heat exchanger 1 is connected to a seawater inlet pipe 7, and a seawater pump 8 is arranged on the seawater inlet pipe 7; The outlet of the heat exchange tube of the heater 3 is connected to a solar heat collector 9 through a pipeline, and the outlet of the solar heat collector 9 is connected to a plurality of spray heads 10 arranged on the top of the first-stage spray tower 4 through a pipeline. The three-stage spray towers 4, 5, and 6 are connected. Each stage of the spray tower is provided with a section of packing 11. There is an evaporat...

Embodiment 2

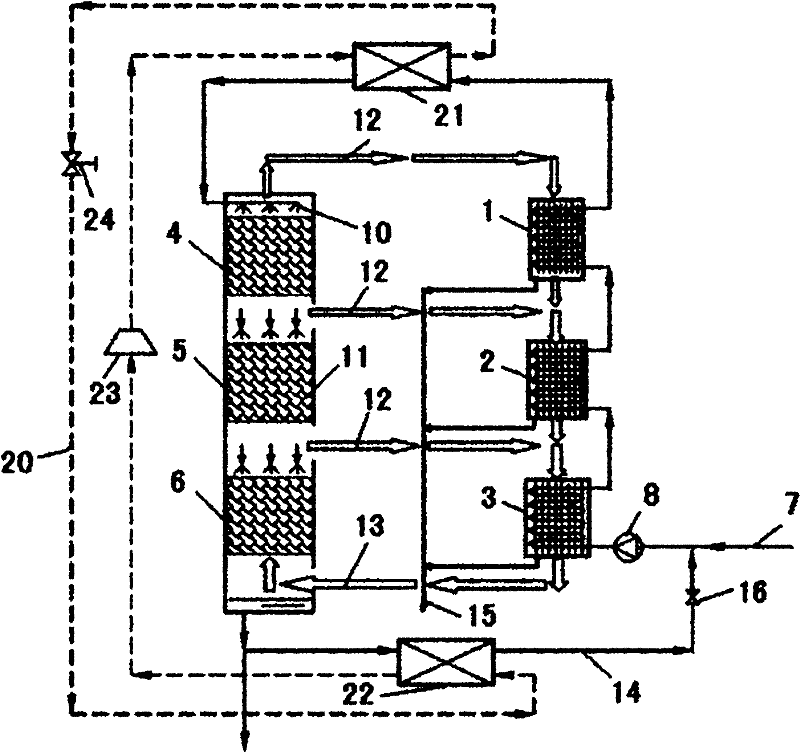

[0027] Such as figure 2 As shown, the basic configuration of this embodiment is the same as that of Embodiment 1, the difference is that the seawater heating device is different, and a set of conventional heat pump circulation system 20 is set to replace the solar heating system 9 . The heat pump circulation system 20 includes: a condenser 21 arranged on the pipeline between the water outlet of the heat exchange tube of the third stage heat exchanger 3 and the water inlet of the first stage spray tower 4, and arranged on the spray seawater discharge pipe 15 An evaporator 22 on the top, a compressor 22 is arranged on the pipeline between the evaporator 21 and the condenser 23, and an expansion valve 24 is arranged on the pipeline between the condenser 21 and the evaporator 22.

[0028] When this embodiment is working, the two countercurrent heat exchange processes are the same as in Embodiment 1, the difference is that: the seawater flowing out from the water outlet of the thi...

Embodiment 3

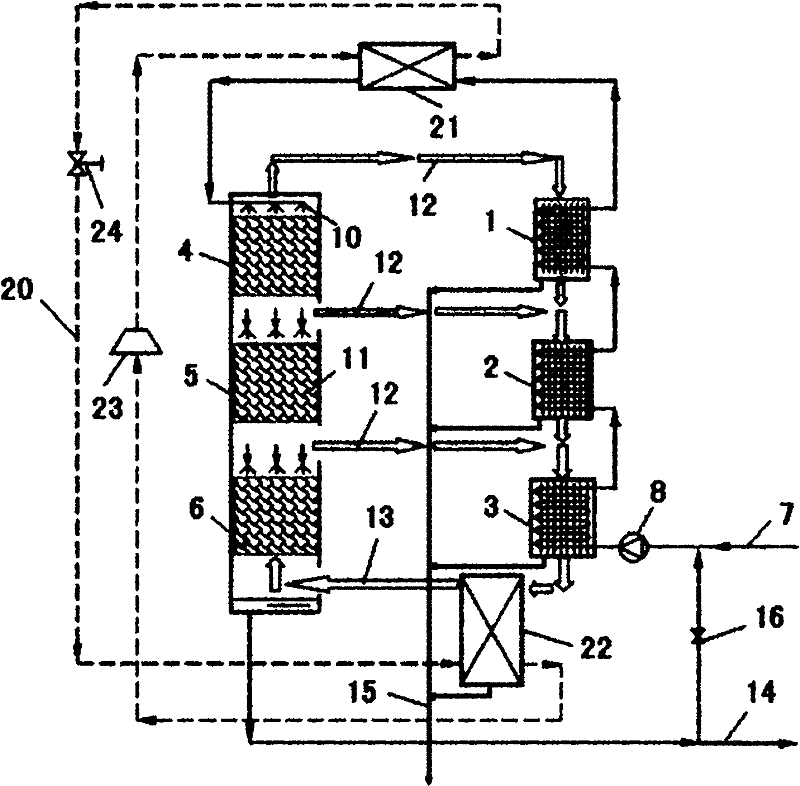

[0030] Such as image 3 As shown, this embodiment is basically the same as Embodiment 2, and a set of conventional heat pump circulation system 20 is also provided. It differs from Embodiment 2 in that: the evaporator 22 is not arranged on the spray seawater discharge pipe 15, but It is arranged on the return air pipe 14 between the bottom of the first-stage heat exchanger 1 and the bottom of the third-stage spray tower 6, and is connected to the fresh water collection pipe 13 in parallel at the bottom of the evaporator 22 through a pipeline.

[0031] When this embodiment works, the difference from Embodiment 2 is that the evaporator 22 absorbs the heat from the low-temperature hot and humid air entering the third-stage spray tower 6 from the first-stage heat exchanger 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com