Method for purifying lysine

A purification method and technology of lysine, applied in the field of lysine purification, can solve the problems of unfavorable process continuous operation, affecting the efficiency of lysine separation and purification, and low lysine purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] This example is used to illustrate the purification method of lysine.

[0070] (1) will be 0.8m 3 Lysine fermentation liquid (lysine content 11.2g / 100ml, purity 59.4% by weight) carries out membrane filtration (membrane material is pottery (membrane surface microporous UF1 aperture 0.1um, UF2 aperture 0.2um), membrane filtration pressure is 1.5bar , membrane filtration temperature is 75 DEG C, and filtration time is 1 hour), obtains the lysine fermented supernatant liquid that the pH value is 3 through membrane filtration, and mixes with washing liquid (the washing liquid that step (3) obtains), and washing liquid The consumption that makes the pH value of the mixed solution containing lysine obtained is 6;

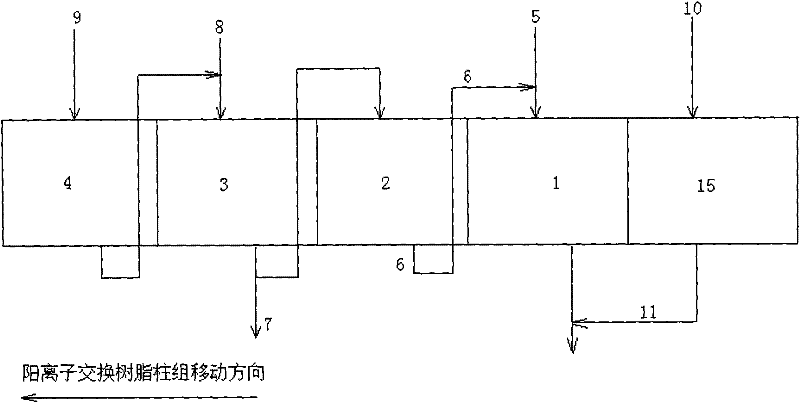

[0071] (2) at 40 DEG C, the solution containing lysine with a pH value of 6 obtained in step (1) is continuously pumped in from the upper end of the resin column group at the first place in the adsorption area (the flow rate of the solution containing lysine is 6...

Embodiment 2

[0078] This example is used to illustrate the purification method of lysine.

[0079] Purify lysine according to the method of Example 1, except that in step (1), the amount of washing liquid is such that the pH value of the resulting mixed solution containing lysine is 3.5. In the obtained lysine eluate, the content of lysine was 21.4 g / 100 ml, and the purity was 96% by weight.

Embodiment 3

[0081] This example is used to illustrate the purification method of lysine.

[0082] According to the method for embodiment 1, lysine is purified, and difference is:

[0083] In step (1), the amount of washing liquid makes the resulting mixed solution containing lysine have a pH value of 3.5;

[0084] In step (2), the temperature of ion exchange is 50°C, the flow rate of the solution containing lysine is 5m / h, and the weight ratio of the solution containing lysine to the resin is 1.6:1;

[0085] In step (3), the temperature of the eluent is 60° C., the flow rate of the eluent is 9.5 m / h, and the weight ratio of the eluent to the resin adsorbed with lysine is 1:1;

[0086] In step (4), the analytical temperature is 60° C., and the adsorbed resin column of step (3) is eluted successively with 5.6% by weight of dilute ammonia water, and the flow rate of ammonia water is 13.6 m / h. The weight ratio of the resin of amino acid is 0.9: 1, and the lysine eluate (purity 96.5% by weig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com