Industrial preparation method for riboflavine sodium phosphate

A technology of sodium riboflavin phosphate and riboflavin phosphate, which is applied in the field of industrial preparation of sodium riboflavin phosphate, can solve problems such as failure to meet quality requirements, high activity of phosphorus oxychloride, and poor reaction selectivity. Achieve the effects of easy mastery of production technology, low production cost and mild production conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

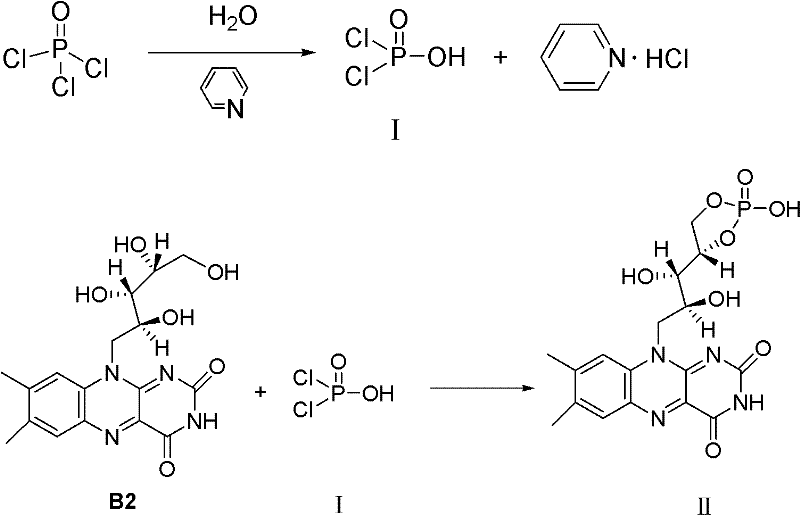

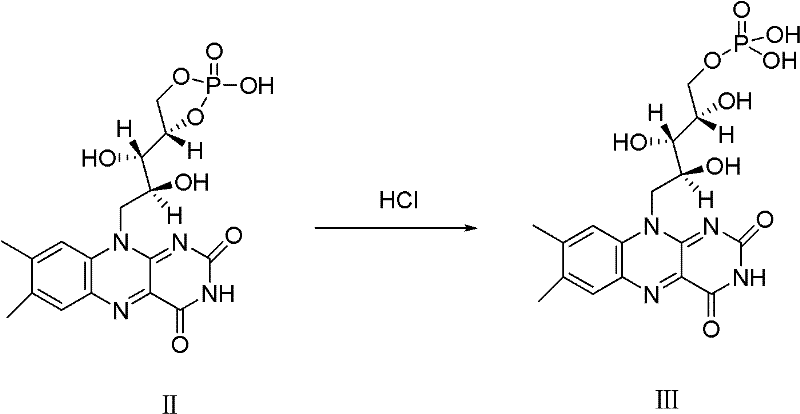

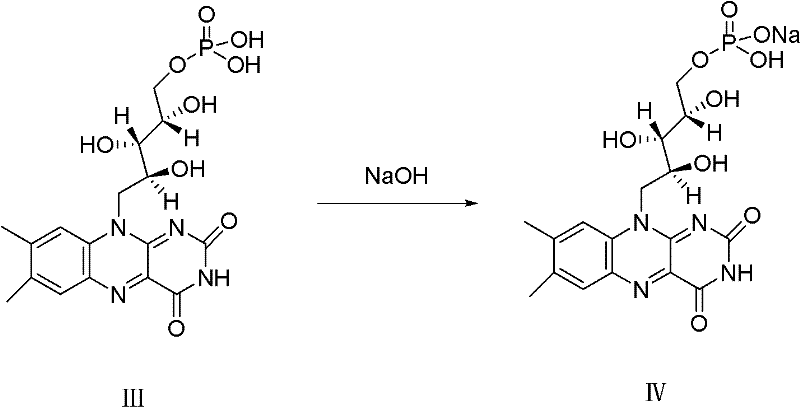

Method used

Image

Examples

Embodiment 1

[0031] 1) Phosphorylation reaction of riboflavin to generate riboflavin cyclic phosphate;

[0032] Extract 180kg (that is, 4390mol) of acetonitrile into the reaction tank, open the jacket and cool the salt to below 8°C. Open the vacuum valve of the pyridine metering tank to accurately extract 126kg of pyridine (1064mol) into the pyridine metering tank. After evacuating the vacuum, open the bottom valve of the metering tank and slowly add pyridine to the reaction tank. ℃. Then accurately extract 244kg (i.e. 1195mol) of phosphorus oxychloride into the metering tank, slowly drip into the reaction tank, and the temperature of the reaction solution is lower than 5°C. 80kg of acetonitrile (i.e. 1951mol) is sucked into the mixed liquid metering tank earlier, and then 12kg of purified water (i.e. 665mol) is sucked in. Close the vacuum valve, the temperature in the reaction tank drops below 5°C, and slowly add the acetonitrile-water mixture to ensure that the temperature is below 10°...

Embodiment 2

[0041] Take 200kg (that is, 4878mol) of acetonitrile into the reaction tank, open the jacket ice salt and cool down to below 5°C. Take 126kg (i.e. 1615mol) of pyridine into the pyridine metering tank. After evacuating the vacuum, open the bottom valve of the metering tank and slowly add pyridine into the reaction tank. Take 260kg (that is, 1688mol) of phosphorus oxychloride into the metering tank, slowly add it to the reaction tank, and the temperature of the reaction solution is lower than 5°C. First pump 100 g (ie 2439 mol) of acetonitrile in the mixed liquid metering tank, and add 10 kg (ie 555 mol) of purified water. When the temperature in the reaction tank drops below 5°C, start to slowly add the acetonitrile-water mixture to ensure that the temperature of the reaction solution is below 10°C during the process. Add 100kg (ie 266mol) riboflavin and react at 5-10°C for 8h. After suction filtration, soak the riboflavin cyclic phosphate filter cake twice with 100kg of acet...

Embodiment 3

[0050] Take 200kg (that is, 2632mol) tetrahydrofuran into the reaction tank, open the jacket ice salt and cool down to below 5°C. Take 126kg (i.e. 1615mol) of pyridine into the pyridine metering tank. After evacuating the vacuum, open the bottom valve of the metering tank and slowly add pyridine into the reaction tank. Take 260kg (that is, 1688mol) of phosphorus oxychloride into the metering tank, slowly add it to the reaction tank, and the temperature of the reaction solution is lower than 5°C. First pump 80kg (ie 1111mol) tetrahydrofuran into the mixed liquid metering tank, and add 12kg (ie 665mol) purified water. When the temperature in the reaction tank drops below 5°C, start to slowly add the acetonitrile-water mixture to ensure that the temperature of the reaction solution is below 10°C during the process. Add 100kg (ie 266mol) of riboflavin (B2) and react at 5-10°C for 8h. After suction filtration, soak the riboflavin cyclic phosphate filter cake with an appropriate a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com