Nickel-copper conductive paste for electronic component electrode and manufacturing technology thereof

A technology for conductive paste and electronic components, which is used in cable/conductor manufacturing, electrical components, conductive materials dispersed in non-conductive inorganic materials, etc. It can solve the problem of insufficient adhesion and achieve the effect of improving adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following describes the nickel-copper conductor paste and its manufacturing process described in the application of the present invention through specific implementation methods, the purpose is for the public to better understand the technical content described in the application of the present invention, not to limit the technical content , in fact, within the spirit of the present invention, the improvements to the process formula, including the increase, decrease and replacement of the corresponding components, can be obtained by those of ordinary skill in the art without creative work, so they are all included in this Within the technical solution claimed in the invention application.

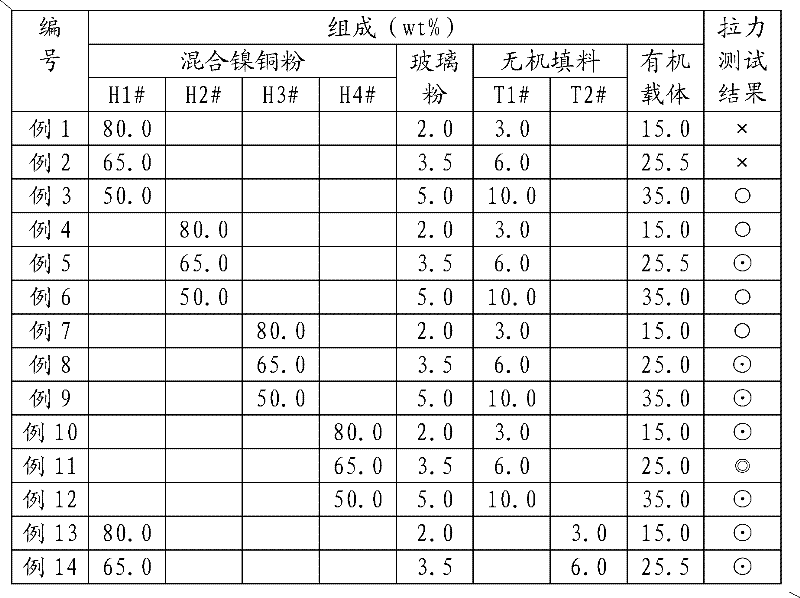

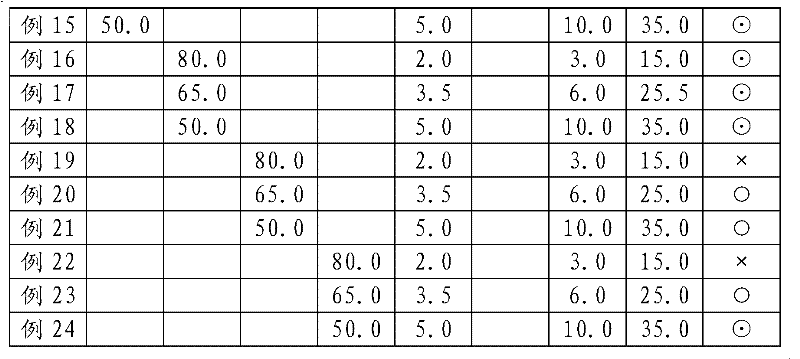

[0022] Here is an example to illustrate the production of nickel-copper conductor paste for electrodes of electronic components. The actual materials used are as follows:

[0023] The preparation of the mixed nickel-copper powder is according to the ratio in Table 1. Accurately w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com