Mechanical straw temperature rising device for sunlight greenhouse

A solar greenhouse and mechanical technology, applied in greenhouse cultivation, air heaters, climate change adaptation, etc., can solve the problems of expensive heating and difficult heating, and achieve the effects of good growth environment, sufficient combustion and uniform heating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

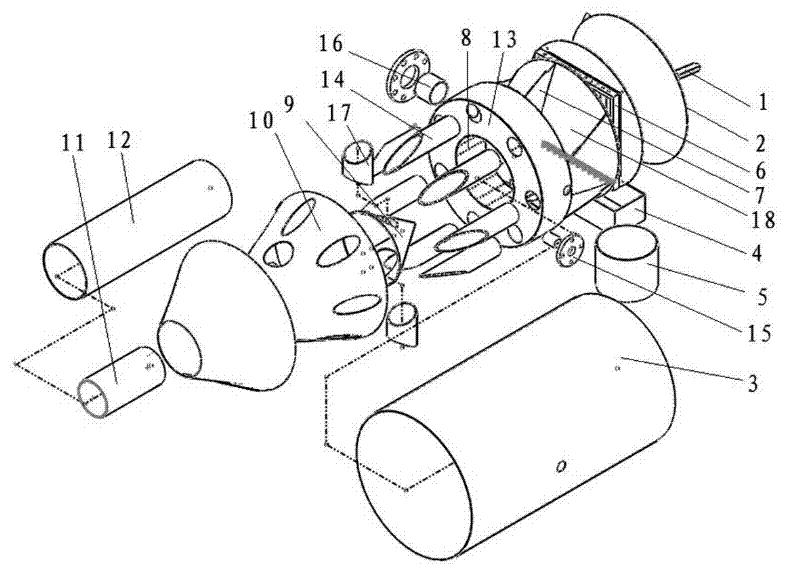

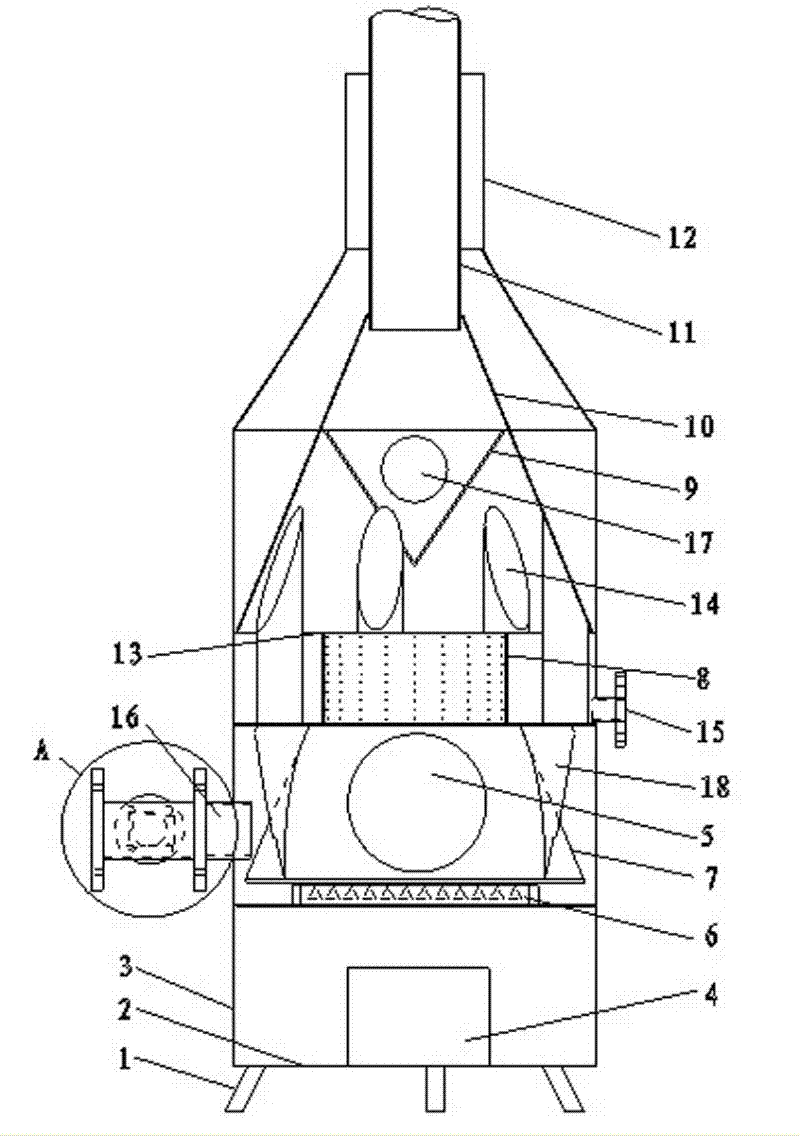

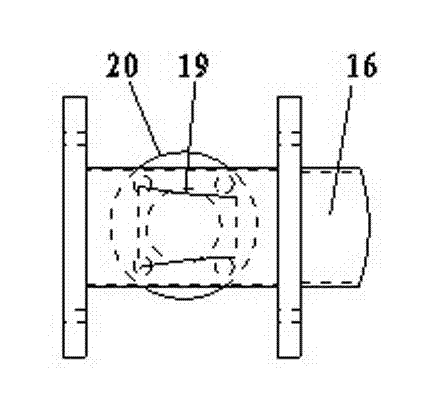

[0029] The specific embodiment of the present invention will be further described in conjunction with the accompanying drawings.

[0030] A mechanical stalk warming device for a solar greenhouse, which includes a furnace outer cylinder 3, a fuel port 5 and an ash outlet 4 are opened on the furnace outer cylinder 3, and a furnace bar assembly 6 is arranged between the fuel port 5 and the ash outlet 4, It is characterized in that a conical primary burner 7, a cylindrical secondary burner 8, a reverse conical fire extinguisher and dust collector 9 and a conical secondary stage heat exchanger 10;

[0031] The bottom of the primary burner 7 is fixed on the outer cylinder 3 of the furnace, and there is a gap between the upper part of the primary burner 7 and the outer cylinder 3 of the furnace, and the top of the primary burner 7 is connected to the bottom of the secondary burner 8;

[0032] The secondary burner 8 has a number of micro-holes, and the secondary burner 8 is cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com