Combined equipment for preparing polymer compound by grinding method

A compound and polymer technology, applied in the chemical industry, can solve problems such as low production efficiency, poor product quality, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

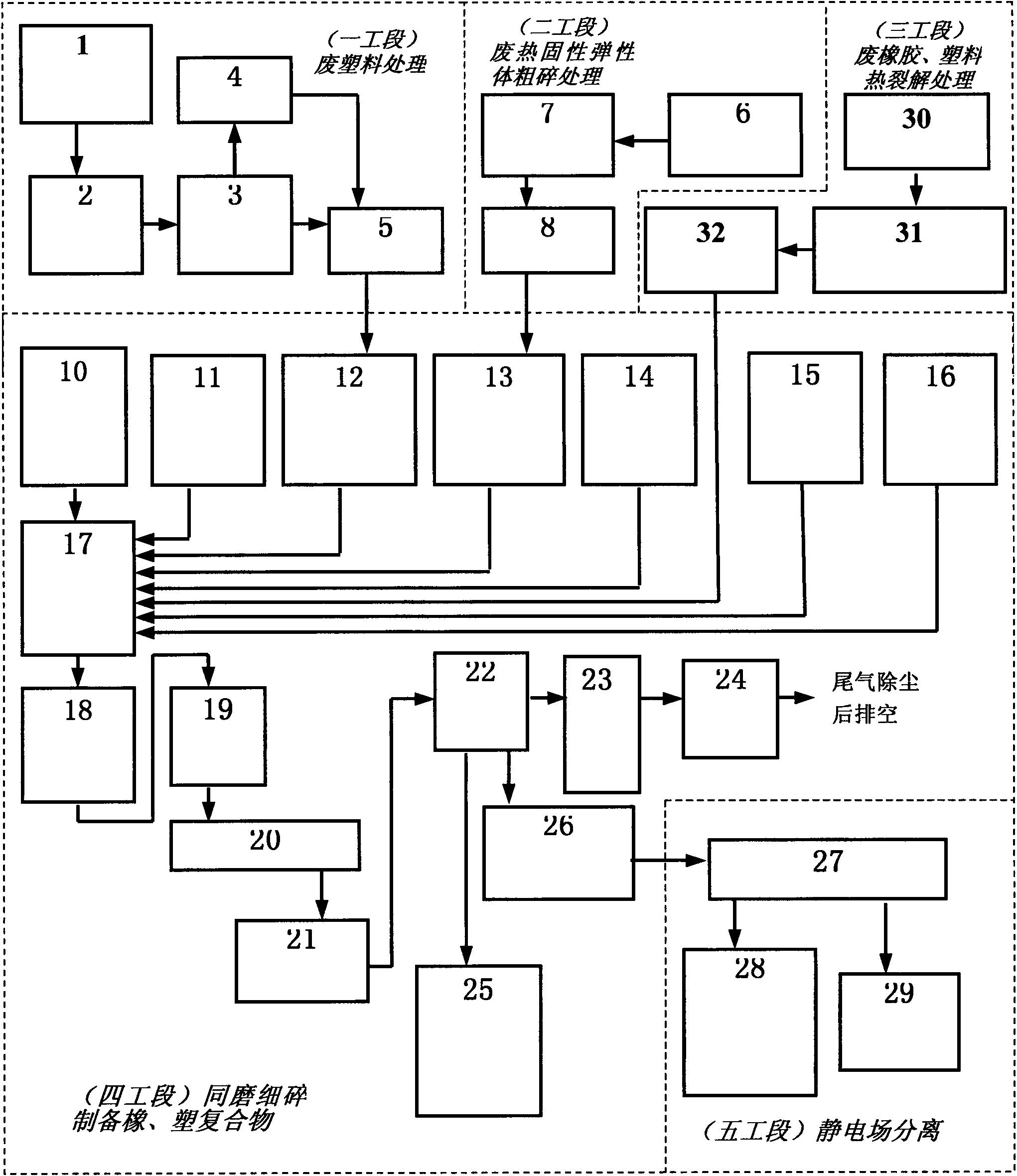

[0063] Such as figure 1 As shown, it is a schematic block diagram of "a combined equipment suitable for preparing polymer composites by milling" described in the present invention, figure 1 Middle 21 is a grinding fine crusher, that is, the normal temperature disc-type elastomer fine grinder equipped with "an improved elastomer fine grinder screw and grinding disc cooperation mechanism" set in the fine crushing sub-combination device I according to the present invention ";

[0064] figure 1 Among them, 10 is the high-level warehouse for new plastic particles, 11 is the high-level warehouse for fillers, 12 is the high-level plastic warehouse for passing through 1-25mm aperture sieves, 13 is the elastomer high-level warehouse for passing 5-30 mesh aperture sieves, and 14 is other additives 15 is the high position warehouse for other additives, 16 is the high position warehouse for other elastomers, 17 is the weighing and batching mechanism, 18 is the stirring and mixing mechan...

Embodiment 2

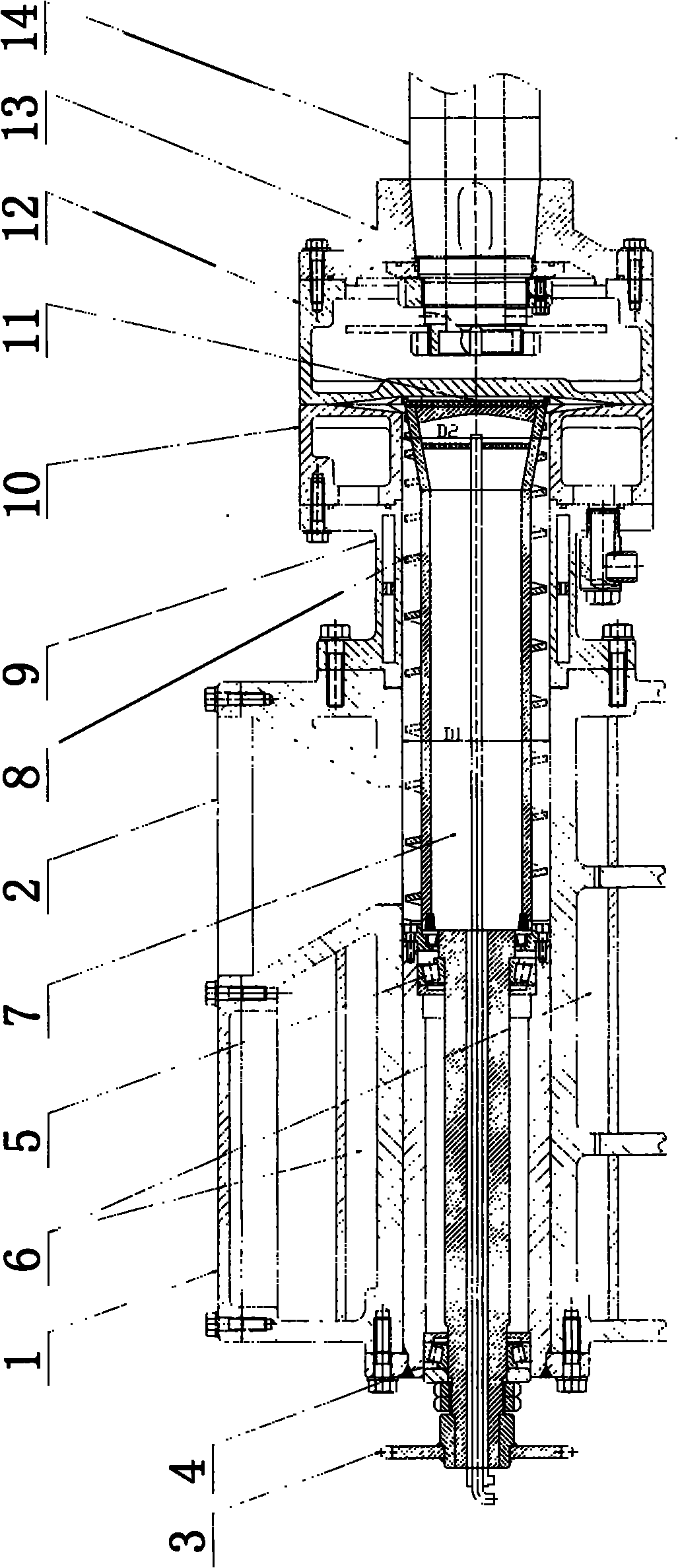

[0074] Such as figure 2 As mentioned above, it is a schematic diagram of an embodiment of the "improved mechanism for the cooperation between the screw and the grinding disc of the elastomer fine grinder" of the present invention, figure 2 Middle: 1 is the body, 2 is the feeding hopper, 3 is the feeding sprocket, 4 is the front bearing device, 5 is the rear bearing device, 6 is the water cooling device; 13 is the dynamic grinding seat, 14 is the transmission main shaft; these are It is a known component on the normal temperature disc type elastomer fine crusher of the prior art;

[0075] 7 is a feed screw provided with a water-cooling device, 8 is a continuous helical tooth with gradually tightening and unequal pitches or / and gradually increasing and unequal tooth heights arranged on the conveying screw, and 9 is a static grinding seat (also a feeding screw) Part of the screw tube), 10 is a static grinding disc, 11 is a lubricating soft filling member, and 12 is a moving gr...

Embodiment 3

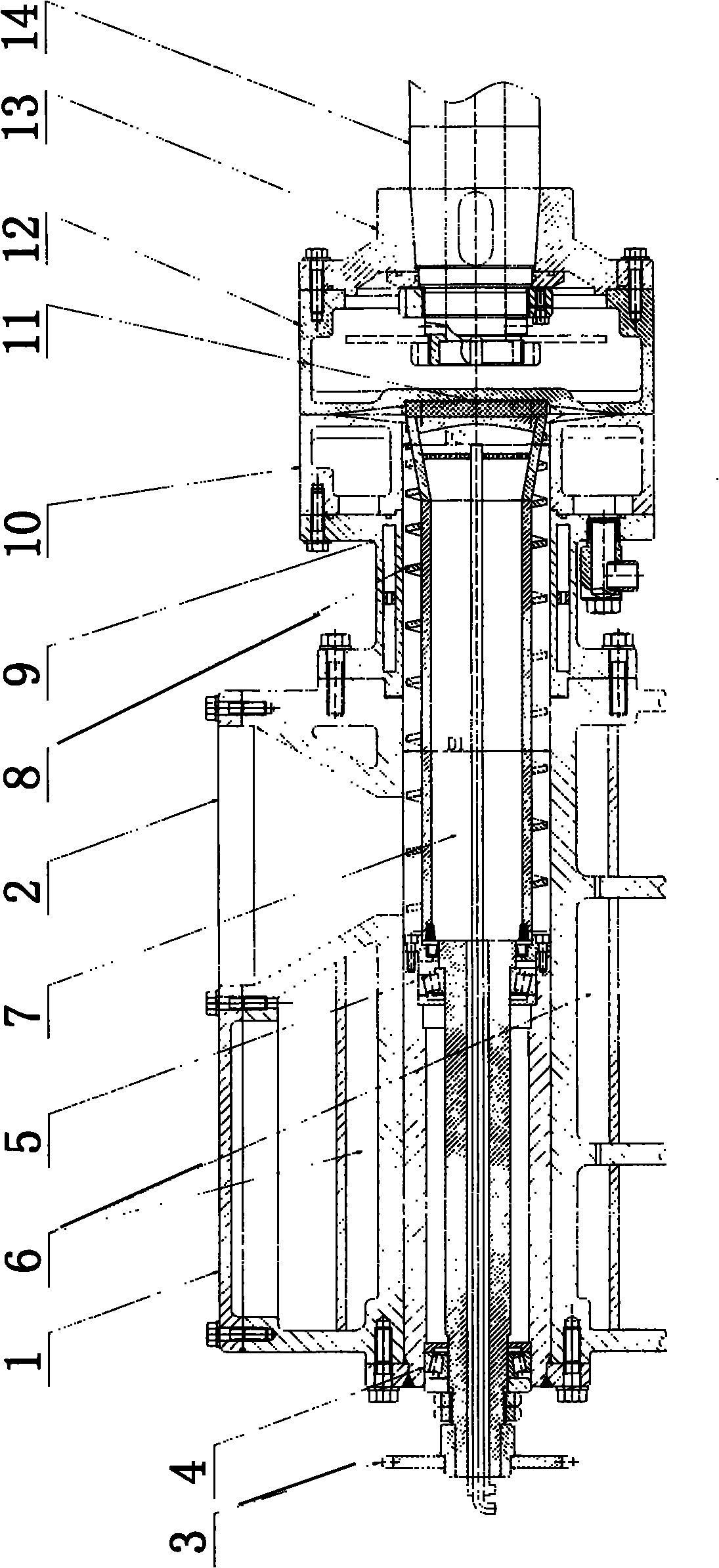

[0081] Such as image 3 As mentioned above, it is a schematic diagram of another embodiment of the "improved mechanism for cooperating between the screw and the grinding disc of the elastomer pulverizer" of the present invention, image 3 Middle: 1 is the body, 2 is the feeding hopper, 3 is the feeding sprocket, 4 is the front bearing device, 5 is the rear bearing device, 6 is the water cooling device; 13 is the dynamic grinding seat, 14 is the transmission main shaft; these are It is a known component on the normal temperature disc type elastomer fine crusher of the prior art;

[0082] 7 is a feeding screw provided with a water-cooling device, 8 is a continuous helical tooth with gradually tightening tooth pitch arranged on the conveying screw, 9 is a static grinding seat (also a part of the feeding screw tube), 10 is a static grinding disc, 11 For lubricating the soft filling member, 12 is a moving grinding disc; these are the screw rod and grinding disc matching mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com