Elementary substance Bi nano-structured material and preparation method and application thereof

A nanostructure and elemental technology, applied in the fields of nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve problems such as not being widely developed and lack of Bi nanostructure materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

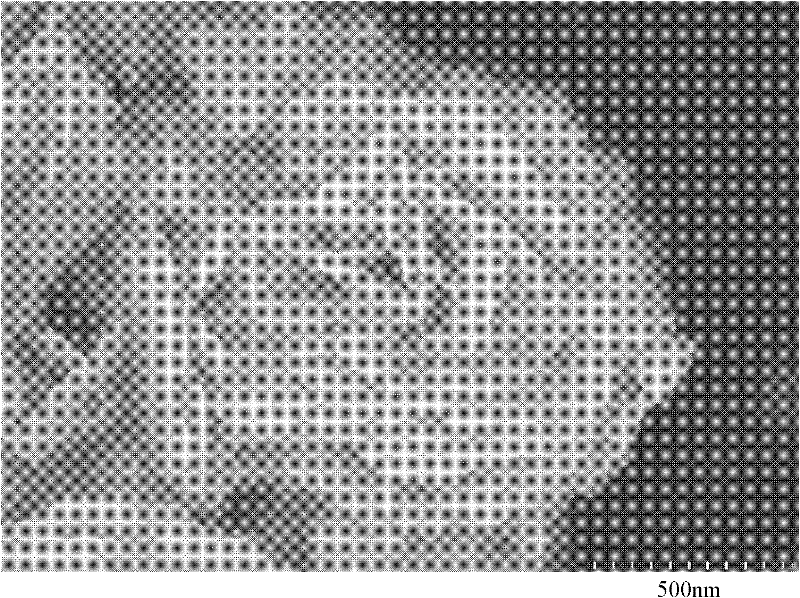

[0019] Example 1. Preparation of Bi elemental nanostructure material

[0020] 0.2g of surfactant sodium polystyrene sulfonate was dissolved in 50g of water and stirred on a magnetic stirrer for 0.8 hours. After it was completely dissolved, 2g of hydrazine hydrate was added and stirred for 0.5 hours, then 0.3g of bismuth trichloride was dispersed in it and stirred 0.8 hours. The obtained white suspension was transferred to a polytetrafluoroethylene lined stainless steel hydrothermal reactor with a capacity of 80 mL, and after sealing, it was placed in an oven and heated at 90°C for 28 hours. After the completion of the reaction, the hydrothermal reactor was allowed to stand to cool down in a room temperature environment. The obtained product was transferred to a centrifuge tube and centrifuged at 1000 rpm for 10 minutes; the precipitate was discarded, the upper suspension was transferred to a centrifuge tube, and centrifuged at 8000 rpm for 15 minutes, and the upper layer was dis...

Embodiment 2

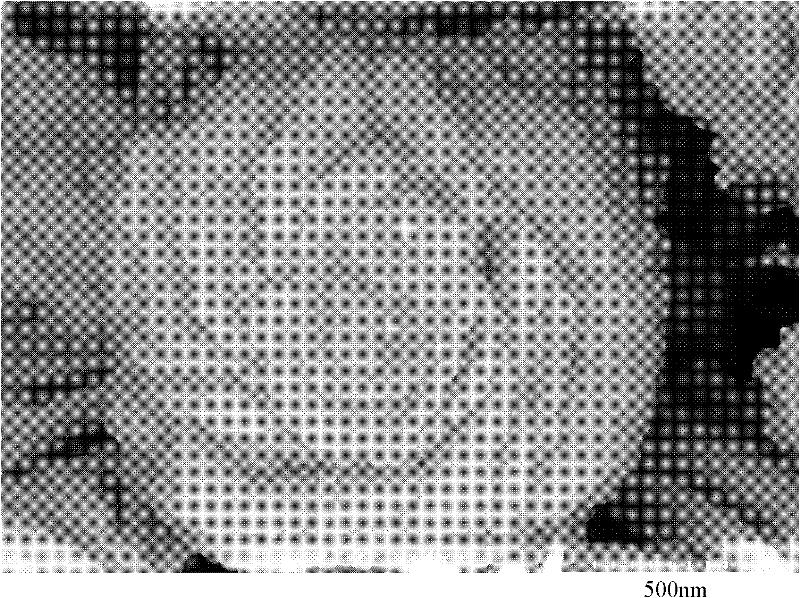

[0023] Example 2. Preparation of Bi elemental nanostructure material

[0024] Dissolve 0.3g of sodium polystyrene sulfonate as a surfactant in 50g of water, stir for 1 hour on a magnetic stirrer, add 1g of hydrazine hydrate and stir for 0.5 hour, then disperse 0.35g of bismuth trichloride in it and stir. 1 hour. The obtained white suspension was transferred to a polytetrafluoroethylene-lined stainless steel hydrothermal reactor with a capacity of 80 mL, and after sealing, it was placed in an oven and heated at 100°C for 26 hours. After the completion of the reaction, the hydrothermal reactor was allowed to stand to cool down in a room temperature environment. The resulting product was transferred to a centrifuge tube and centrifuged at a speed of 1500 rpm for 12 minutes; the precipitate was discarded, the upper suspension was transferred to a centrifuge tube, and centrifuged at a speed of 10,000 rpm for 15 minutes, and the upper layer was discarded liquid. The product obtained...

Embodiment 3

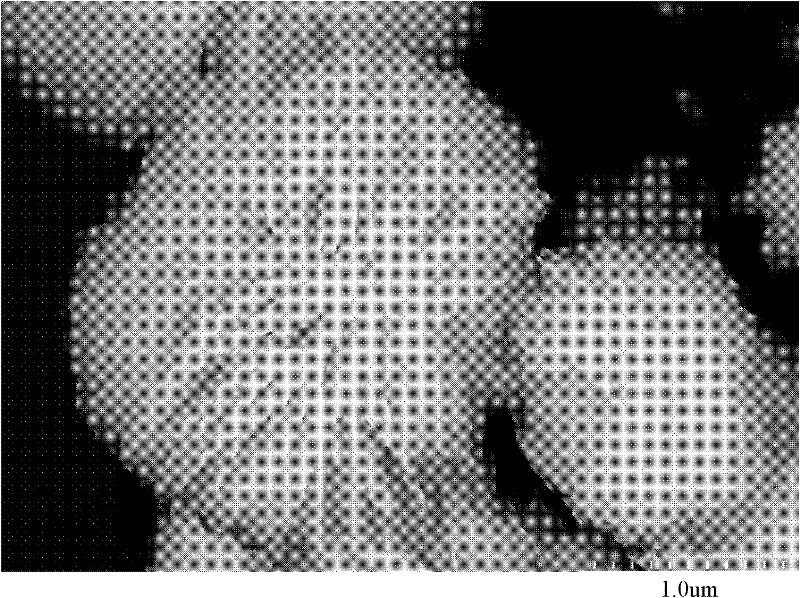

[0027] Example 3. Preparation of Bi elemental nanostructure material

[0028] 0.4g of surfactant sodium polystyrene sulfonate was dissolved in 50g of water, stirred on a magnetic stirrer for 0.5 hours, after complete dissolution, 2.5g of hydrazine hydrate was added, stirred for 1 hour, and 0.4g of bismuth trichloride was dispersed in it. Stir for 0.5 hour. The obtained white suspension was transferred to a polytetrafluoroethylene-lined stainless steel hydrothermal reactor with a capacity of 80 mL, and after sealing, it was placed in an oven and heated at 110°C for 24 hours. After the completion of the reaction, the hydrothermal reactor was allowed to stand to cool down in a room temperature environment. The obtained product was transferred to a centrifuge tube and centrifuged at 1000 rpm for 15 minutes; the precipitate was discarded, the upper suspension was transferred to a centrifuge tube, and centrifuged at 10,000 rpm for 15 minutes, and the upper layer was discarded liquid....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com