1-methyl cyclopropene slow release formulation and preparation method thereof

A technology of methylcyclopropene and sustained-release agent, which is applied in the field of 1-methylcyclopropene corrosion inhibitor and its preparation, can solve the problems of low content, short sustained-release time, and short fresh-keeping time of fruits and vegetables, and achieve extended release time , long release time and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

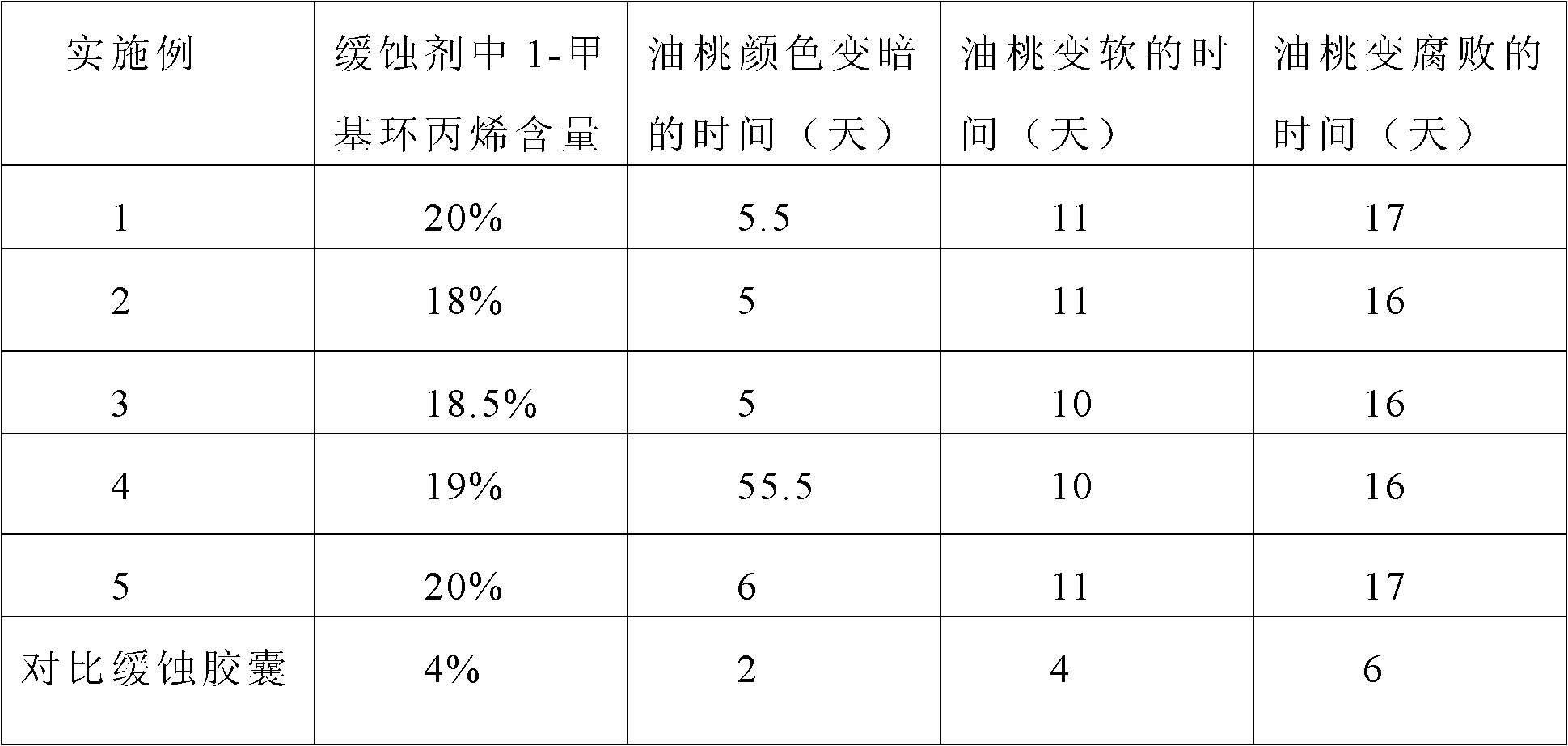

Examples

Embodiment 1

[0024] A kind of 1-methylcyclopropene slow-release agent, coating film material is gelatin, core material is 1-methylcyclopropene, when preparing described 1-methylcyclopropene slow-release agent, the 1-methylcyclopropene used The usage weight ratio of cyclopropene and gelatin raw material is 20:100.

[0025] The preparation method of the 1-methylcyclopropene slow-release agent comprises the following steps successively:

[0026] 1) Add an appropriate amount of water into the reaction vessel, then add a certain amount of gelatin, stir to form a 10% solution by weight, put it in an ice bath, and control its temperature at 1-4°C;

[0027] 2) adding 1-methylcyclopropene equivalent to 20% by weight of gelatin into the reaction vessel, and stirring at a speed of 1000 rpm until a uniform gelatin-coated microemulsion of 1-methylcyclopropene is formed;

[0028] 3) Add sodium sulfate equal to the weight of gelatin for precipitation, and the 1-methylcyclopropene microemulsion will sett...

Embodiment 2

[0034] A 1-methylcyclopropene sustained-release agent, the coated film material is gelatin, and the core material is 1-methylcyclopropene. When preparing the 1-methylcyclopropene slow-release agent, the weight ratio of the 1-methylcyclopropene to the gelatin raw material used is 20:100.

[0035] Its preparation method comprises the following steps in turn:

[0036] 1) Add a certain amount of water into the reaction vessel, and then add a certain amount of gelatin to form a 2% solution by weight, put it in an ice bath, and control its temperature at 1-4°C;

[0037] 2) adding 1-methylcyclopropene equivalent to 20% by weight of gelatin into the reaction vessel, and stirring at a speed of 1000 rpm until a uniform gelatin-coated microemulsion of 1-methylcyclopropene is formed;

[0038] 3) adding 2% peach gum solution in parts by weight for precipitation, adjusting the pH value to 4 with acetic acid to complete the precipitation, and continuing to stir for 30 minutes;

[0039] 4) ...

Embodiment 3

[0044] A 1-methylcyclopropene sustained-release agent, the coating material is gelatin, and the core material is 1-methylcyclopropene. When preparing the 1-methylcyclopropene slow-release agent, the weight ratio of the 1-methylcyclopropene to the gelatin raw material used is 15:100.

[0045] Its preparation method comprises the following steps in turn:

[0046] 1) Add a certain amount of water into the reaction vessel, and then add a certain amount of gelatin to prepare a 6% solution by weight, put it in an ice bath, and control its temperature at 1-4°C;

[0047] 2) adding 1-methylcyclopropene equivalent to 15% by weight of gelatin into the reaction vessel, and stirring at a speed of 1000 rpm until a uniform gelatin-coated microemulsion of 1-methylcyclopropene is formed;

[0048] 3) adding sodium sulfate equal to the weight of gelatin for salting out and precipitation, and continuing to stir for 30 minutes;

[0049] 4) Add glutaraldehyde which is 5% by weight of gelatin to s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com