Manufacturing method of crocodile bone powder

A production method and crocodile bone technology are applied in medical preparations containing active ingredients, bone diseases, pharmaceutical formulations, etc., which can solve the problems of loss of calcium and trace elements, high power consumption, and many impurities, and prevent bone loss. Porosis, easy absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

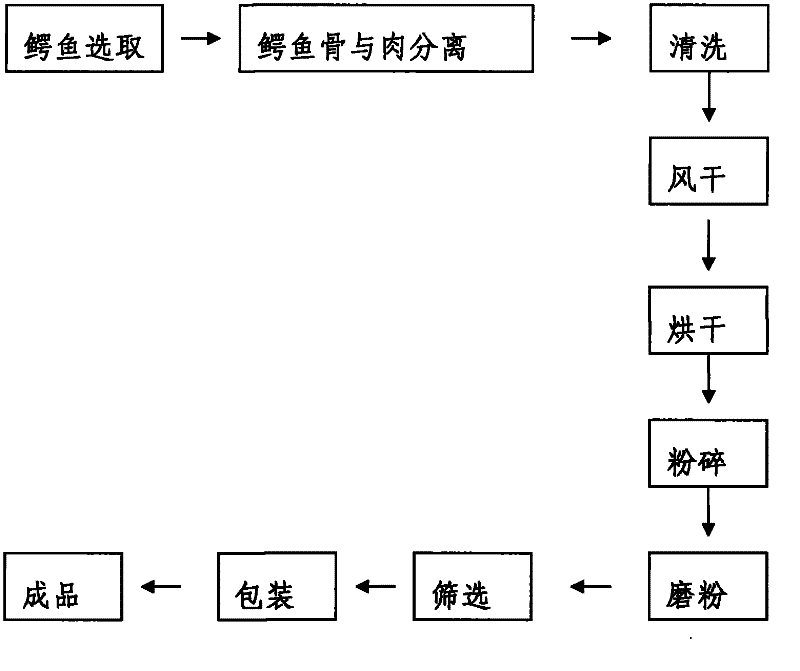

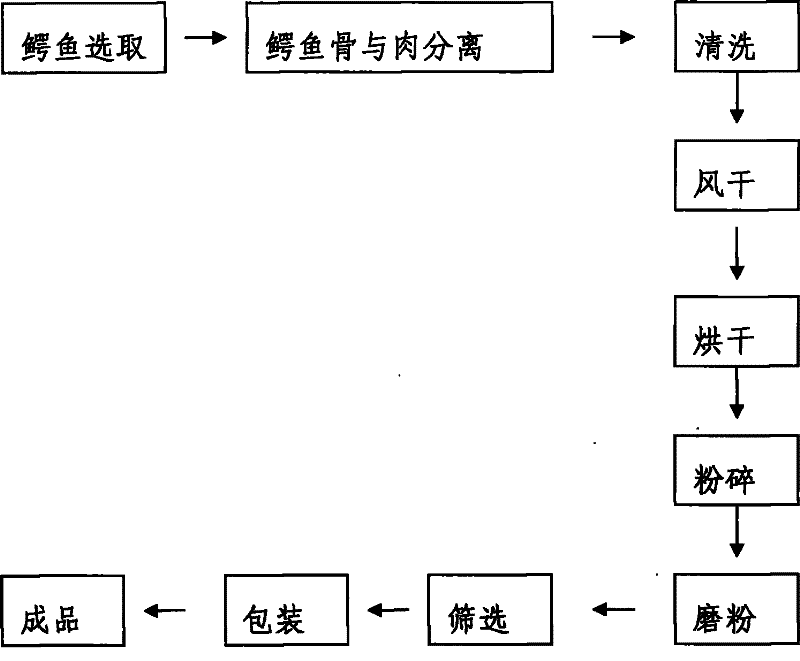

Image

Examples

Embodiment 1

[0010] Embodiment 1: the preparation method of crocodile bone powder

[0011] (1) Crocodile selection: crocodiles are selected from natural or artificially bred crocodiles;

[0012] (2) After the crocodile is slaughtered, separate the bone from the meat: put the crocodile bone with a small amount of meat into the normal saline solution (0.9% sodium chloride aqueous solution) boiled in the pressure cooker, continue to boil and pressurize for 20 minutes , use physiological saline and add fire to boil, pressurize time should not be too long, to ensure that calcium and trace elements will not be lost;

[0013] (3) Cleaning: Take out the boiled crocodile bones from the pressure cooker, remove the meat, soak them in clear water, wash them repeatedly, and then continue soaking and disinfecting them in salt water with a concentration of 2 to 4%. Good effect, low cost, deodorizing, easy to buy and easy to operate and many other advantages, and finally washed repeatedly with clean wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com