Improved aeration well for in-situ remediation of polluted underground water and remediation method

An in-situ repair and groundwater technology, applied in the direction of oxidized water/sewage treatment, etc., can solve the problems of inapplicability of sites with high pollutant concentrations and long repair time, so as to reduce repair costs and maintenance costs, reduce The effect of lateral diffusion and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

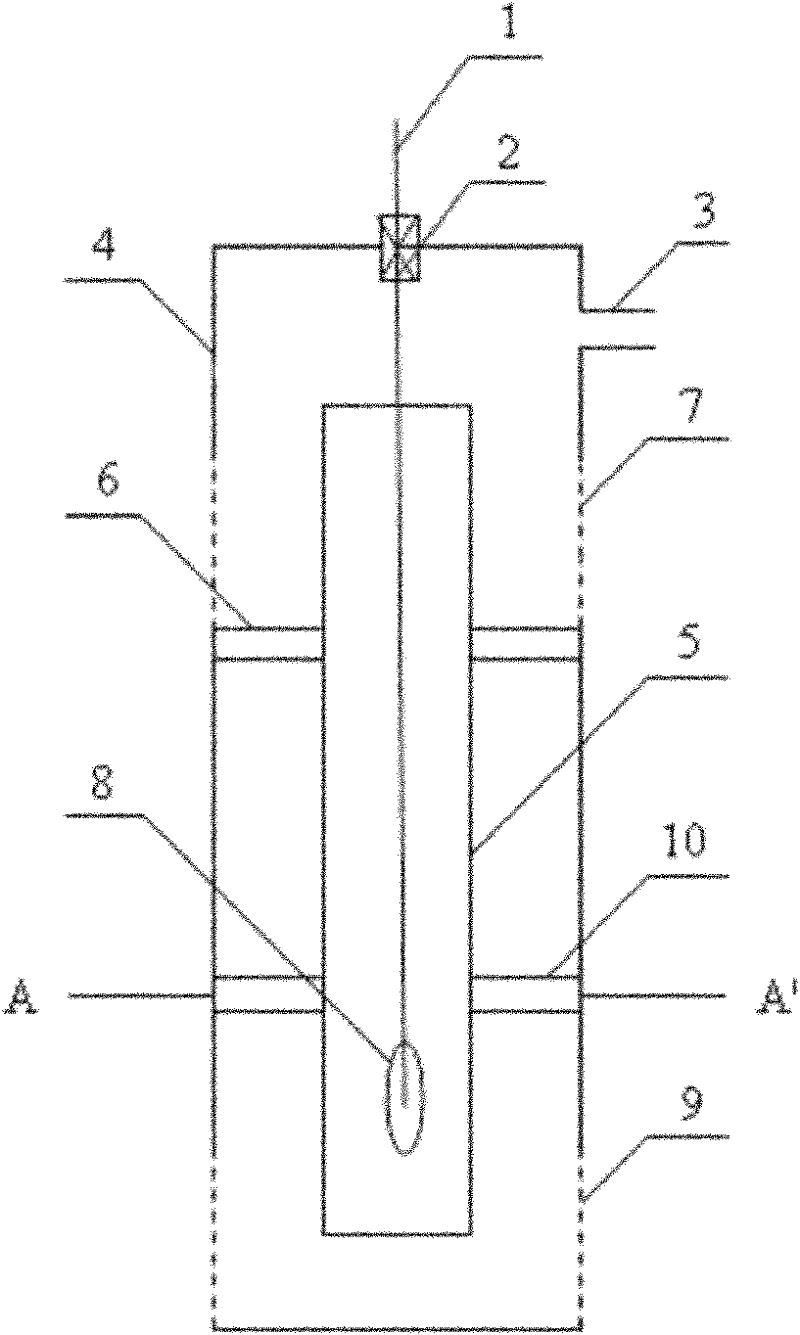

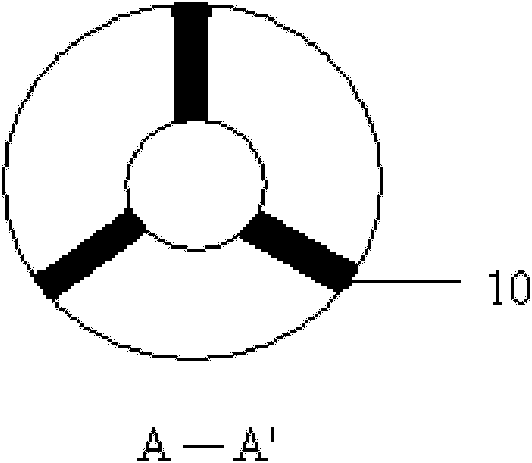

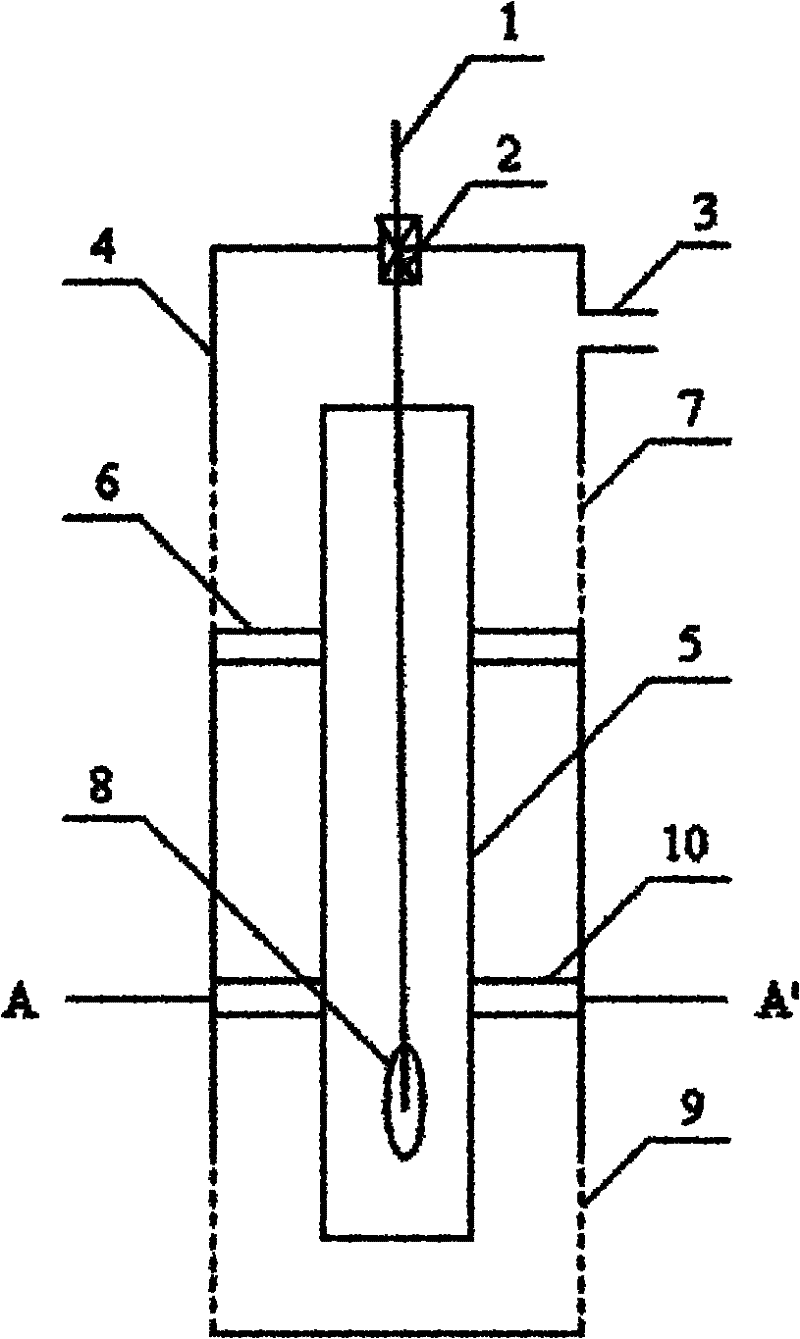

[0037] The improved aeration well for repairing polluted groundwater in situ is that the inner well pipe 5 is set inside the outer well pipe 4, and the inner well pipe is fixed in the outer well pipe 4 by the upper fixing bracket and the lower fixing bracket 10, and the inner well pipe The lower part of 5 is equipped with an aeration head 8, and the aeration head 8 is connected with the aeration pump through the aeration pipe 1 and the regulating valve 2 fixed on the top of the outer well pipe 4. The air hole 3 is connected to the polluting gas monitor, the top of the inner well pipe 5 is lower than the vent hole 3, and the lower part of the upper vent hole 3 of the outer well pipe 4 is provided with an upper flower tube 7, and the top hole of the upper flower tube 7 is lower than the inner well pipe. Well pipe 5, the lower section of outer well pipe 4 is provided with lower floral tube 9, the top hole of lower floral tube 9 is higher than the bottom end surface of inner well p...

Embodiment 2

[0050] The improved aeration well for repairing polluted groundwater in situ is that the inner well pipe 5 is set inside the outer well pipe 4, and the inner well pipe is fixed in the outer well pipe 4 by the upper fixing bracket and the lower fixing bracket 10, and the inner well pipe The lower part of 5 is equipped with an aeration head 8, and the aeration head 8 is connected with the aeration pump through the aeration pipe 1 and the regulating valve 2 fixed on the top of the outer well pipe 4. The air hole 3 is connected to the polluting gas monitor, the top of the inner well pipe 5 is lower than the vent hole 3, and the lower part of the upper vent hole 3 of the outer well pipe 4 is provided with an upper flower tube 7, and the top hole of the upper flower tube 7 is lower than the inner well pipe. Well pipe 5, the lower section of outer well pipe 4 is provided with lower floral tube 9, the top hole of lower floral tube 9 is higher than the bottom end surface of inner well p...

Embodiment 3

[0063] The improved aeration well for repairing polluted groundwater in situ is that the inner well pipe 5 is set inside the outer well pipe 4, and the inner well pipe is fixed in the outer well pipe 4 by the upper fixing bracket and the lower fixing bracket 10, and the inner well pipe The lower part of 5 is equipped with an aeration head 8, and the aeration head 8 is connected with the aeration pump through the aeration pipe 1 and the regulating valve 2 fixed on the top of the outer well pipe 4. The air hole 3 is connected to the polluting gas monitor, the top of the inner well pipe 5 is lower than the vent hole 3, and the lower part of the upper vent hole 3 of the outer well pipe 4 is provided with an upper flower tube 7, and the top hole of the upper flower tube 7 is lower than the inner well pipe. Well pipe 5, the lower section of outer well pipe 4 is provided with lower floral tube 9, the top hole of lower floral tube 9 is higher than the bottom end surface of inner well p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com