Method for producing organic fertilizer by fermentation method

A technology of organic fertilizer and fermentation method, which is applied in the field of compost fermentation to produce organic fertilizer, which can solve the problems of manpower-consuming cleaning and repairing ventilation pipes, affecting the quality of organic fertilizer products, and damaging ventilation pipes, etc., and achieves low operation and maintenance costs and is convenient for promotion , Complete effect of sterilization and deodorization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

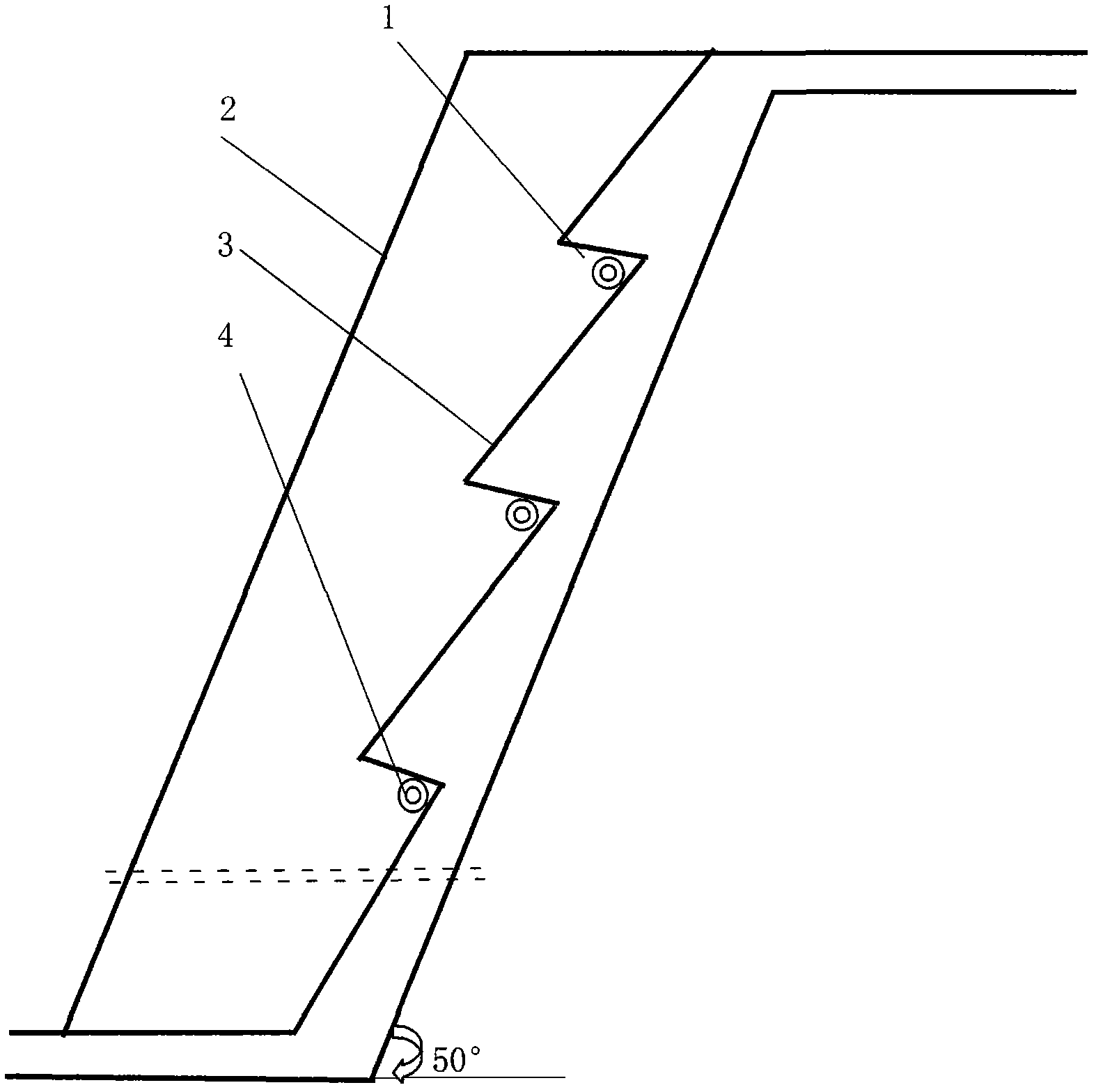

[0023] Embodiment 1: Utilize livestock and poultry manure as raw material, take mushroom dregs, bran and humic acid soil as auxiliary materials, add organic material decomposing agent in the prior art, through uniform stirring, adopt artificial ventilation to carry out composting fermentation, after Ripe to produce organic fertilizer. The fermentation adopts slope fermentation, that is, the fermentation tank is built on the slope, and the fermentation tank with multiple slope staggered layers is built by using the hillside terrain, and the "hanging rock" formed by the adjacent slope staggered layers is used as the ventilation channel. A timed air blower is installed outside each ventilation channel to blow air to supply oxygen, thus forming a static aeration system. The specific operation is as follows:

[0024] 1. Construction of slope-type fermentation facilities: as shown in Figure 1, the fermentation tank is built on the slope by using the hillside terrain, and the origin...

Embodiment 2

[0029] Embodiment 2: the specific implementation process of this embodiment is as follows, and other conditions are the same as embodiment 1.

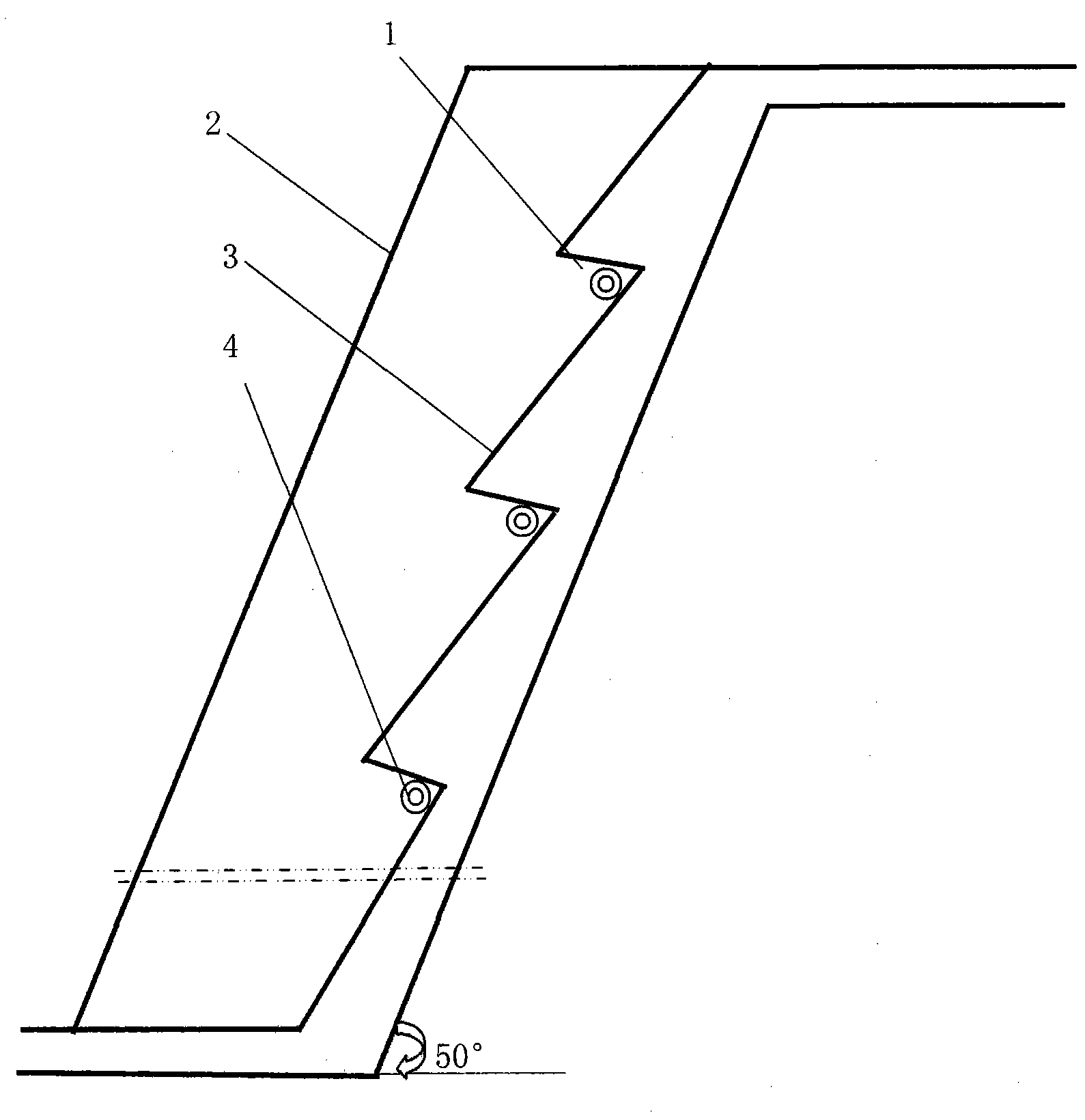

[0030] 1. Slope-type fermentation facility construction: use the hillside terrain to build the fermentation tank on the slope. The tank depth is 1.2 meters, the tank width is 2.0 meters, the tank length is 10 meters, the slope of the fermentation tank is 45°, and the slope through the bottom of the tank is 1.0 meters apart. The staggered layers form a "hanging rock" as a ventilation channel, and a small blower is installed outside the tank to blow air.

[0031] 2. Ingredients, mixing and stacking: Turn on the special organic fertilizer production mixer, add 1 ton of chicken manure, 0.4 tons of bran and 140 grams of organic material decomposing agent into the mixer, stir evenly, and then put the evenly mixed fermentation materials from The upper end of the fermentation tank is poured in, and the fermentation tank is automatically slid d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com