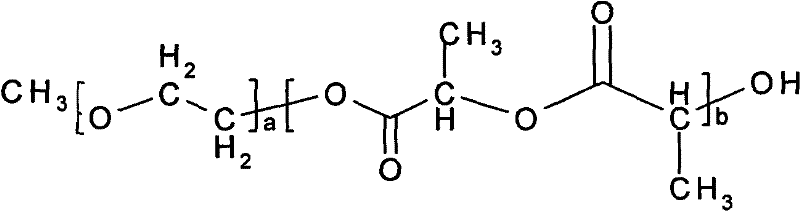

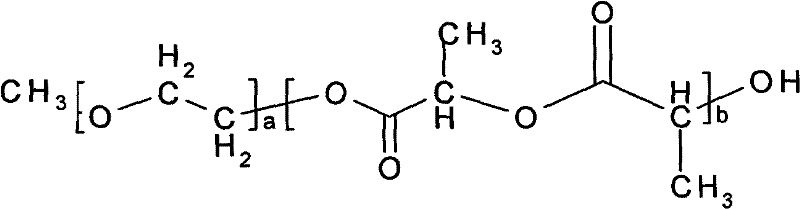

Preparation method of polyethylene glycol monomethyl ether-dl-polylactic acid block copolymer

A technology of polyethylene glycol monomethyl ether and block copolymer, which is applied in the field of preparation of polyethylene glycol monomethyl ether-dl-polylactic acid block copolymer, which can solve the problems of reaction temperature limitation and achieve simple operation Convenience, small loss and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1. Add one of the solvents of cumene, xylene, anisole, dimethylformamide, and dimethyl sulfoxide into a dry reactor according to Table 1. For example, adding three to five times the total amount of anisole according to the preset raw material input, adding the catalyst stannous octoate, and a certain proportion of polyethylene glycol monomethyl ether 2000, dl-lactide according to Table 1. Stir and dissolve evenly. Add nitrogen to remove air. Then it is heated to react. The heating temperature is limited to 110°C and 180°C depending on the solvent used. The reaction time is then set between 4 hours and 12 hours. Then stop the reaction.

[0019] 2. Slowly pour the viscous reactant into the petroleum ether-carbon dioxide dry ice paste mixture while stirring vigorously. Place and filter to get a white solid. Dry in a vacuum oven at 40°C for 24 hours. A white solid of polyethylene glycol monomethyl ether-dl-polylactic acid block copolymer was obtained.

[0020] 3. The str...

Embodiment 2

[0036] 1. Add one of the solvents of cumene, xylene, anisole, dimethylformamide, and dimethyl sulfoxide into the dry reactor according to Table 1, such as the amount according to the preset ratio 3 to 5 times the cumene, followed by adding polyethylene glycol monomethyl ether 2000 and dl-lactide in a certain proportion according to Table 1. Stir and dissolve evenly. After the temperature was raised to 120°C, a catalytic amount of stannous octoate was added, and nitrogen gas was introduced to remove air. Then it is heated to react. The heating temperature is limited to between 120°C and 180°C depending on the solvent used. The reaction time is then set between 4 hours and 12 hours. Then stop the reaction.

[0037] 2. Vacuum distillation try to remove the solvent under reduced pressure. Add polyethylene glycol monomethyl ether-dl-polylactic acid block copolymer in a good solvent such as dichloromethane or methanol, which is 2-8 times the amount, and stir to help dissolve it. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com