Production equipment and production process of environment-friendly epoxy zinc-rich anti-corrosion powder coating

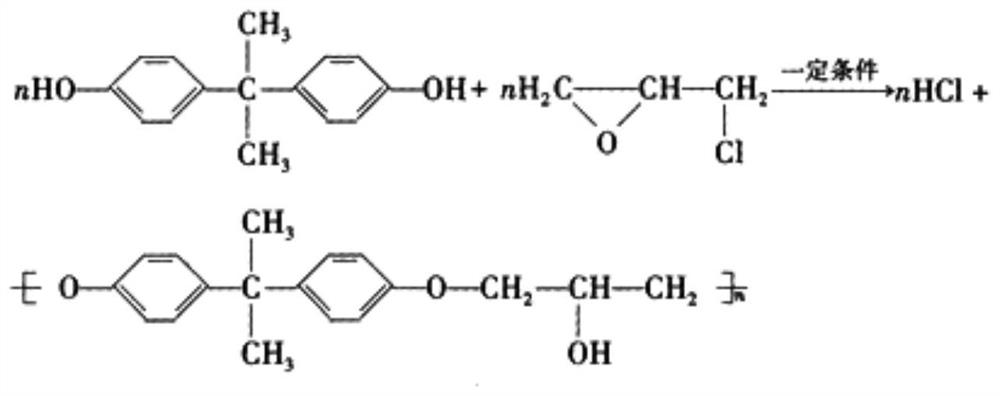

An epoxy zinc-rich powder coating technology, which is applied in powder coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve the problem of affecting the bonding force of the upper coating and zinc-rich coating, reducing the anti-corrosion performance of the coating, and inconvenient mixing and fusion and other problems, the production conditions are not harsh, the salt spray resistance performance is improved, and the preparation method is optimized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

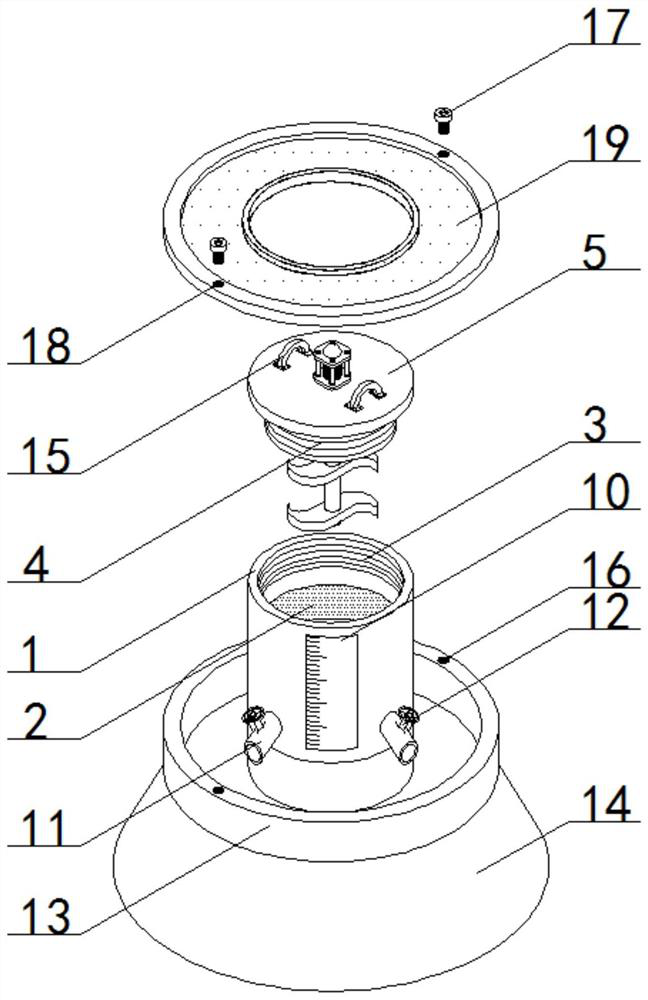

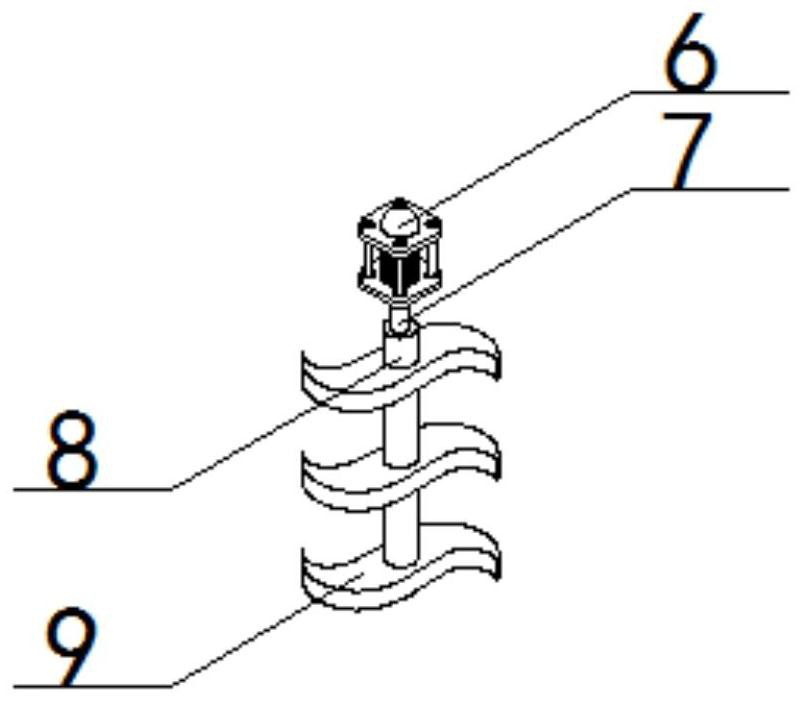

Image

Examples

Embodiment 1

[0059] The present embodiment epoxy zinc-rich anticorrosion powder coating is made up of the raw material of following weight portion:

[0060] E-12 epoxy resin 40%, novolak epoxy resin 10%, trimethylhexamethylenediamine 5%, aminopropyltriethoxysilane 2%, dimethylimidazole 1%, polyvinyl alcohol Butyraldehyde 3%, zinc powder 14%, nano powder 3%, graphene powder 3%, ethylene bis stearamide 4%, antioxidant 5%, composite filler 10%. The zinc powder is zinc powder with a particle diameter of 5 μm.

[0061] The composite filler consists of the following percentages of raw materials: glass flakes 40%, xylene 20%, aluminum silicate 20%, nano jade powder 6%, nitride nano powder 2%, hydroxide nano powder 2%, rare earth powder 3%, Polyethylene glycol 4%, octyl di-n-octyl tin 3%.

[0062] Composite fillers are prepared by the following methods:

[0063] (1) Stir the glass flakes and xylene at 20°C for 15 minutes, mix the aluminum silicate according to the above percentage, stir at 60°C...

Embodiment 2

[0074] The present embodiment epoxy zinc-rich anticorrosion powder coating is made up of the raw material of following weight portion:

[0075] E-12 epoxy resin 40%, novolak epoxy resin 10%, trimethylhexamethylenediamine 5%, aminopropyltriethoxysilane 2%, dimethylimidazole 1%, polyvinyl alcohol Butyraldehyde 3%, zinc powder 14%, nano powder 3%, graphene powder 3%, ethylene bis stearamide 4%, antioxidant 5%, composite filler 10%. The zinc powder is zinc powder with a particle diameter of 20 μm.

[0076] The composite filler consists of the following percentages of raw materials: glass flakes 40%, xylene 20%, aluminum silicate 20%, nano jade powder 6%, nitride nano powder 2%, hydroxide nano powder 2%, rare earth powder 3%, Polyethylene glycol 4%, octyl di-n-octyl tin 3%.

[0077] Composite fillers are prepared by the following methods:

[0078] (1) Stir the glass flakes and xylene at 20°C for 15 minutes, mix the aluminum silicate according to the above percentage, stir at 60°...

Embodiment 3

[0089] The present embodiment epoxy zinc-rich anticorrosion powder coating is made up of the raw material of following weight portion:

[0090] E-12 epoxy resin 40%, novolak epoxy resin 10%, trimethylhexamethylenediamine 5%, aminopropyltriethoxysilane 2%, dimethylimidazole 1%, polyvinyl alcohol Butyraldehyde 3%, zinc powder 14%, nano powder 3%, graphene powder 3%, ethylene bis stearamide 4%, antioxidant 5%, composite filler 10%. The zinc powder is zinc powder with a particle diameter of 15 μm.

[0091] The composite filler consists of the following percentages of raw materials: glass flakes 40%, xylene 20%, aluminum silicate 20%, nano jade powder 6%, nitride nano powder 2%, hydroxide nano powder 2%, rare earth powder 3%, Polyethylene glycol 4%, octyl di-n-octyl tin 3%.

[0092] Composite fillers are prepared by the following methods:

[0093] (1) Stir the glass flakes and xylene at 20°C for 15 minutes, mix the aluminum silicate according to the above percentage, stir at 60°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| salt spray resistance time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com