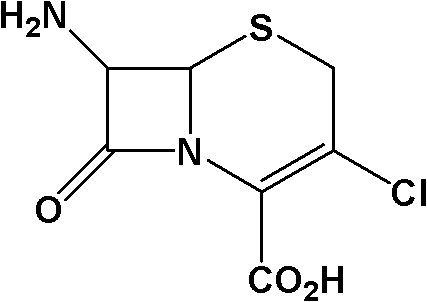

Method for preparing 7-ACCA

A technology for controlling temperature and phenylacetamide, applied in the field of preparation of 7-ACCA

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

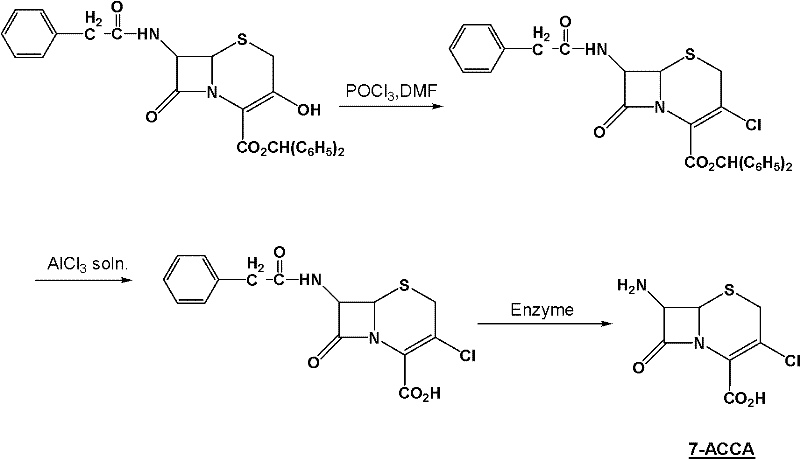

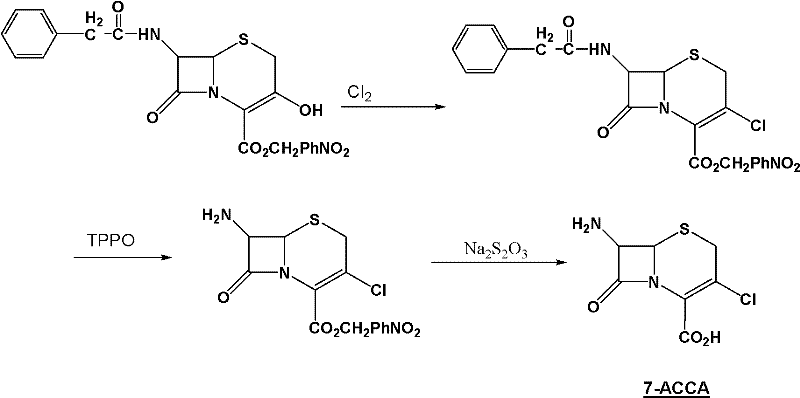

Method used

Image

Examples

Embodiment 1

[0031] 1) Preparation of 7-phenylacetamido-3-chloro-3-cephalosporin-4-carboxylic acid p-nitrobenzyl ester:

[0032] Take 400g of chloroform, 68g of triphosgene (triphosgene, chemical name, bis(trichloromethyl)carbonate, referred to as BTC), 72g of DMF, control the temperature at 0±1°C, stir for 2 hours, add 60g 7-phenylacetamido-3-hydroxyl-3-cephalosporin-4-carboxylic acid p-nitrobenzyl ester, controlled temperature 55±2°C, stirred and reacted for 10 hours, and slowly poured into 150g (10 %, mass percentage concentration) in NaOH solution, control pH 12~13, control temperature 25 ± 2 ℃, stir reaction for 1 hour, stand still, separate layers, distill off chloroform under reduced pressure, add methanol 150g, cool and crystallize, filter, After washing and drying, 54.7 g of p-nitrobenzyl 7-phenylacetamido-3-chloro-3-cephalosporin-4-carboxylate was obtained, with a purity of more than 98%;

[0033] 2) Preparation of 7-phenylacetamido-3-chloro-3-cephalosporin-4-carboxylic acid:

...

Embodiment 2

[0038] 1) Preparation of 7-phenylacetamido-3-chloro-3-cephalosporin-4-carboxylic acid p-nitrobenzyl ester:

[0039] Take 5000g of chloroform, 800g of triphosgene (triphosgene, chemical name, bis(trichloromethyl)carbonate, referred to as BTC), 1000g of DMF, control the temperature at 0±1°C, stir for 3 hours, add 600g 7-phenylacetamido-3-hydroxyl-3-cephalosporin-4-carboxylic acid p-nitrobenzyl ester, controlled temperature 55±2°C, stirred and reacted for 12 hours, and slowly poured into 2000g (10 %, mass percentage concentration) in NaOH solution, control pH 12~13, control temperature 25 ± 2 ℃, stir reaction for 1 hour, stand still, separate layers, distill off chloroform under reduced pressure, add methanol 2000g, cool and crystallize, filter, Washing and drying to obtain 550 g of 7-phenylacetamido-3-chloro-3-cephalosporin-4-carboxylic acid p-nitrobenzyl ester product with a purity of more than 98%;

[0040] 2) Preparation of 7-phenylacetamido-3-chloro-3-cephalosporin-4-carbox...

Embodiment 3

[0045] 1) Preparation of 7-phenylacetamido-3-chloro-3-cephalosporin-4-carboxylic acid p-nitrobenzyl ester:

[0046] Take 2000g of chloroform, 430g of triphosgene (triphosgene, chemical name, bis(trichloromethyl)carbonate, referred to as BTC), 450g of DMF, control the temperature at 0±1°C, stir for 3 hours, add 300g 7-phenylacetamido-3-hydroxyl-3-cephalosporin-4-carboxylic acid p-nitrobenzyl ester, controlled temperature 55±2°C, stirred and reacted for 12 hours, and slowly poured into 1000g (10 %, mass percent concentration) in NaOH solution, control pH 12~13, control temperature 25 ± 2 ℃, stir reaction for 1 hour, stand still, separate layers, distill off chloroform under reduced pressure, add methanol 700g, cool and crystallize, filter, After washing and drying, 270 g of p-nitrobenzyl 7-phenylacetamido-3-chloro-3-cephalosporin-4-carboxylate was obtained, with a purity of more than 98%;

[0047] 2) Preparation of 7-phenylacetamido-3-chloro-3-cephalosporin-4-carboxylic acid: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com