Vanadium-titanium magnetite blast furnace smelting method capable of improving vanadium yield

A technology of vanadium-titanium magnetite and blast furnace smelting, which is applied in the field of steelmaking to achieve the effects of accelerating reduction, good promotion and application value, and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

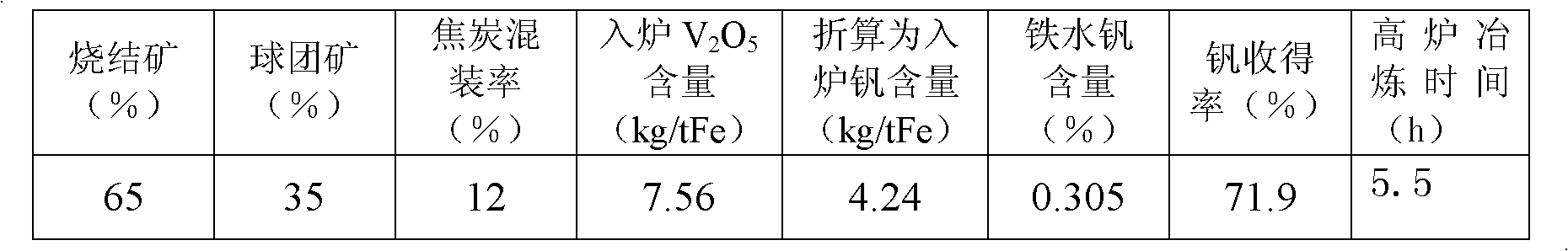

[0024] Embodiment one uses the inventive method to smelt vanadium-titanium magnetite

[0025] Preparation of sintered ore: 35% of vanadium-titanium magnetite concentrate, 45% of ordinary iron ore, 5% of fuel (coke powder) and flux: 8.5% of limestone and 6.5% of quicklime according to the weight ratio. Adding water and mixing, the amount of water added is 7% of the total weight of the above raw materials, and then sintering with gas ignition, the sintering temperature is 1200-1350°C, and the sintering time is 45 minutes. Then the sintered ore is obtained by crushing and screening. Sinter basicity CaO / SiO 2 For: 2.4.

[0026] Preparation of vanadium-titanium pellets: adding 1.8% bentonite to the raw vanadium-titanium magnetite concentrate according to the weight ratio, mixing, moistening and grinding, forming pellets, drying and oxidizing roasting. The drying method is draft drying, the wind speed is 1-1.5 m / s, the initial drying temperature is 50-100°C, the preheating temper...

Embodiment 2

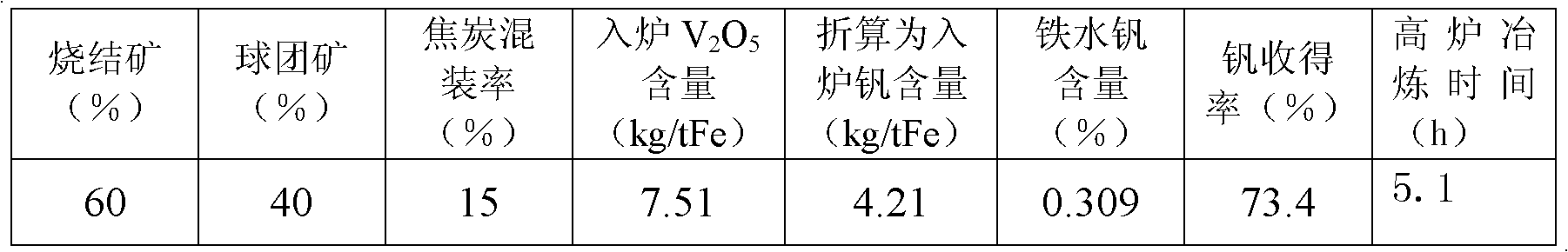

[0030] Embodiment two uses the inventive method to smelt vanadium-titanium magnetite

[0031] Preparation of sintered ore: 38% of vanadium-titanium magnetite concentrate, 42% of ordinary iron ore, 5% of fuel (coke powder) and flux: 7.5% of limestone and 7.5% of quicklime in proportion by weight. Adding water and mixing, the amount of water added is 7.2% of the total weight of the above raw materials, and then sintering with gas ignition, the sintering temperature is 1200-1350°C, and the sintering time is 45 minutes. Then crush and sieve to obtain sintered ore. Sinter basicity CaO / SiO 2 For: 2.45.

[0032] Preparation of vanadium-titanium pellets: adding 1.8% bentonite to the raw vanadium-titanium magnetite concentrate according to the weight ratio, mixing, moistening and grinding, forming pellets, drying and oxidizing roasting. The drying method is draft drying, the wind speed is 1-1.5 m / s, the initial drying temperature is 50-100°C, the preheating temperature is 400-800°C,...

Embodiment 3

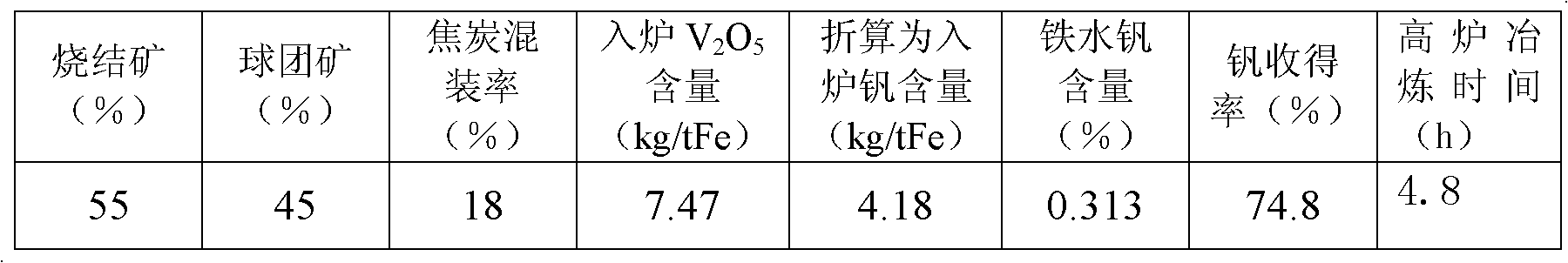

[0036] Embodiment three uses the inventive method to smelt vanadium-titanium magnetite

[0037] Preparation of sintered ore: 40% of vanadium-titanium magnetite concentrate, 40% of ordinary iron ore, 5% of fuel (coke powder) and flux: 6.5% of limestone and 8.5% of quicklime according to the weight ratio. Adding water and mixing, the amount of water added is 7.5% of the total weight of the above raw materials, and then sintering with gas ignition, the sintering temperature is 1200-1350°C, and the sintering time is 45 minutes. Then crush and sieve to obtain sintered ore. Sinter basicity CaO / SiO 2 For: 2.50.

[0038] Preparation of vanadium-titanium pellets: adding 1.8% bentonite to the raw vanadium-titanium magnetite concentrate according to the weight ratio, mixing, moistening and grinding, forming pellets, drying and oxidizing roasting. The drying method is draft drying, the wind speed is 1-1.5 m / s, the initial drying temperature is 50-100°C, the preheating temperature is 40...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mana absorption | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com