Electro-spray disinfection equipment

A sterilization equipment, electrospray technology, applied in electrostatic spraying device, spraying device, preservation of meat/fish through radiation/electrical treatment, etc., can solve problems such as inactivation, high technical requirements for equipment, bacterial breakdown, etc., and achieve structural Simple, good sterilization effect, convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

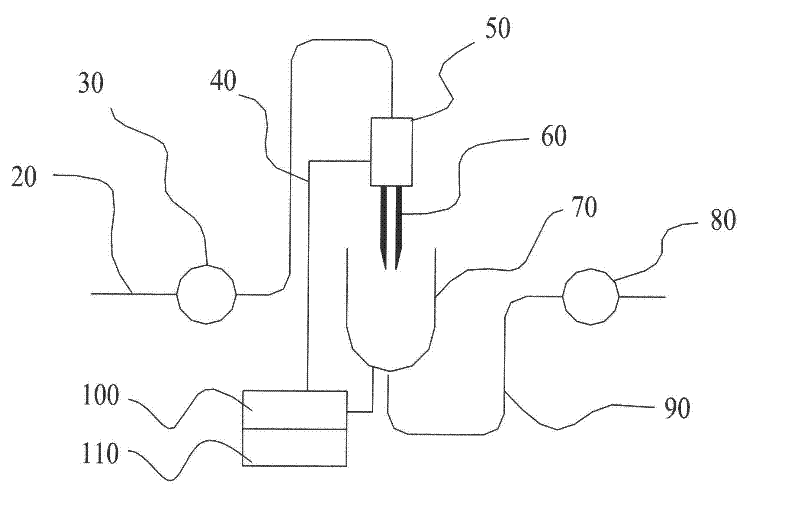

[0021] according to figure 1 The structure shown is assembled with electrospray sterilization equipment, including a voltage device 100 and a voltage connector sleeve 50. The positive electrode of the voltage device 100 is connected to the voltage connector sleeve 50 through a cable 40, and the outlet of the voltage connector sleeve 50 is a hollow capillary tube emitting The needle 60, wherein the voltage connector sleeve 50 is made of metal iron. The voltage of the voltage device 100 is a pulse voltage, wherein the voltage value is 100V; the inlet of the voltage joint sleeve 50 is connected with the input pipeline 20 and the feed delivery pump 30; the width of the outlet end of the hollow capillary emitting needle 60 is 10 mm; The outlet end of the capillary emission needle 60 is opposite to the collection container 70, and the collection container 70 is connected to the discharge delivery pump 80 through the output pipe 90, and the collection container 70 is connected to the...

Embodiment 2

[0025] according to figure 1 The structure shown is assembled with electrospray sterilization equipment, including a voltage device 100 and a voltage connector sleeve 50. The positive electrode of the voltage device 100 is connected to the voltage connector sleeve 50 through a cable 40, and the outlet of the voltage connector sleeve 50 is a hollow capillary tube emitting The needle 60, wherein the voltage connector sleeve 50 is made of metal iron. The voltage of the voltage device 100 is a random pulse voltage, the voltage value of which is 1000V; the inlet of the voltage joint sleeve 50 is connected with the input pipeline 20 and the feeding pump 30; the width of the outlet end of the hollow capillary emitting needle 60 is 8 mm; The outlet end of the hollow capillary emitting needle 60 is opposite to the receiving collection container 70, the collection container 70 is connected to the discharge delivery pump 80 through the output pipe 90, and the collection container 70 is c...

Embodiment 3

[0029] according to figure 1The structure shown is assembled with electrospray sterilization equipment, including a voltage device 100 and a voltage connector sleeve 50. The positive electrode of the voltage device 100 is connected to the voltage connector sleeve 50 through a cable 40, and the outlet of the voltage connector sleeve 50 is a hollow capillary tube emitting The needle 60, wherein the voltage connector sleeve 50 is made of metal iron. The voltage of the voltage device 100 is a unidirectional sine wave voltage, the voltage value of which is 5000V; the inlet of the voltage joint sleeve 50 is connected with the input pipeline 20 and the feeding pump 30; the width of the outlet end of the hollow capillary emitting needle 60 is 0.5 mm; the outlet end of the hollow capillary launch needle 60 is connected to the receiving collection container 70, and the collection container 70 is connected to the discharge delivery pump 80 through the output pipeline 90, and the collecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Voltage value | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com