Preparation method of high-purity coal tar pitch from industrial coal tar pitch

A coal pitch, high-purity technology, applied in the processing of tar pitch/petroleum pitch/natural pitch, processing tar pitch/petroleum pitch/natural pitch by distillation, and processing tar pitch/petroleum pitch/natural pitch by selective extraction, etc. It can solve the problems that the requirements of high-purity graphite raw materials cannot be met, the requirements of high-purity graphite raw materials cannot be met, and chemical impurities have not been removed, and the effect of high recovery rate, short process and lower production costs can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

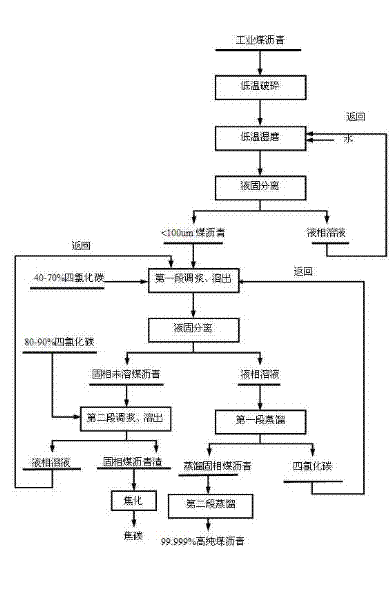

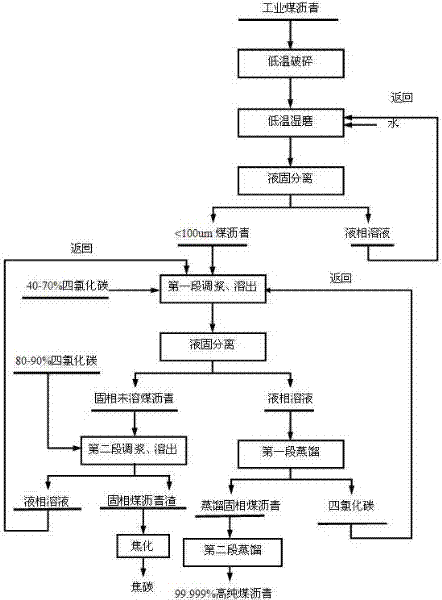

[0007] Example 1. The content of Zn in industrial coal tar pitch is 4.2%, the content of Al is 1.25%, the content of Ti is 0.95%, the content of Fe is 1.35%, and the total ash content is 6.10%. The coal tar pitch is crushed at low temperature, wet-milled, and liquid-solid separated to obtain a material with a particle size of <100um.

[0008] Mix the obtained coal tar pitch with a particle size of <100um and 50% carbon tetrachloride into a reactor with a volume of 3 liters, and react for 8 hours at a temperature of 20-25°C. This is the first stage of slurry mixing. Dissolution. After the reaction time is up, liquid-solid separation is carried out to obtain the dissolved solid-phase coal tar pitch and the organic liquid phase solution containing coal tar pitch molecules. The obtained organic liquid phase solution is charged into a distiller to enter the first stage of distillation process. Heating up to 80-85°C and reaction pressure <0.2Mpa for 5 hours of reaction time, no ca...

Embodiment 2

[0011] Example 2. The content of Zn in industrial coal tar pitch is 3.2%, the content of Al is 1.45%, the content of Ti is 0.75%, the content of Fe is 1.63%, and the total ash content is 6.50%. The coal tar pitch is first subjected to low-temperature crushing, wet grinding, and liquid-solid separation to obtain a raw material with a particle size of <100um.

[0012] Mix the obtained coal tar pitch with a particle size of <100um and 60% carbon tetrachloride together, this is the first stage of slurry mixing and dissolution: add it to a reactor with a volume of 3 liters, and react for 7 hours at a temperature of 30-35°C , after the reaction time is up, liquid-solid separation is carried out to obtain the dissolved solid phase coal tar pitch and the organic liquid phase solution containing coal tar pitch molecules, and the obtained organic liquid phase is loaded into a distiller to enter the first stage of distillation process. Raise the temperature and heat, the temperature is 9...

Embodiment 3

[0015] Example 3. The content of Zn in industrial coal tar pitch is 2.8%, the content of Al is 1.04%, the content of Ti is 0.75%, the content of Fe is 1.65%, and the total ash content is 6.10%. The coal tar pitch is first crushed at low temperature, wet-milled, and liquid-solid separated to obtain a material with a particle size of <100um.

[0016] The obtained coal tar pitch preparation with a particle size of <100um is slurried together with 70% carbon tetrachloride, and added to a reactor with a volume of 3 liters. The temperature is 40-45°C, and the reaction is carried out for 5 hours. After the reaction time is up, the liquid-solid separation is carried out to obtain the leached solid phase coal tar pitch and the organic liquid phase solution containing coal tar pitch molecules. The obtained organic liquid phase is loaded into a distiller and enters the first stage of distillation process. Raise the temperature and heat, the temperature is 100-105°C, and the reaction tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com