Method for extracting oleuropein from olive leaves

A technology of olive leaves and oleuropein, which is applied in the field of extracting oleuropein, and can solve the problem of insufficient oleuropein products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

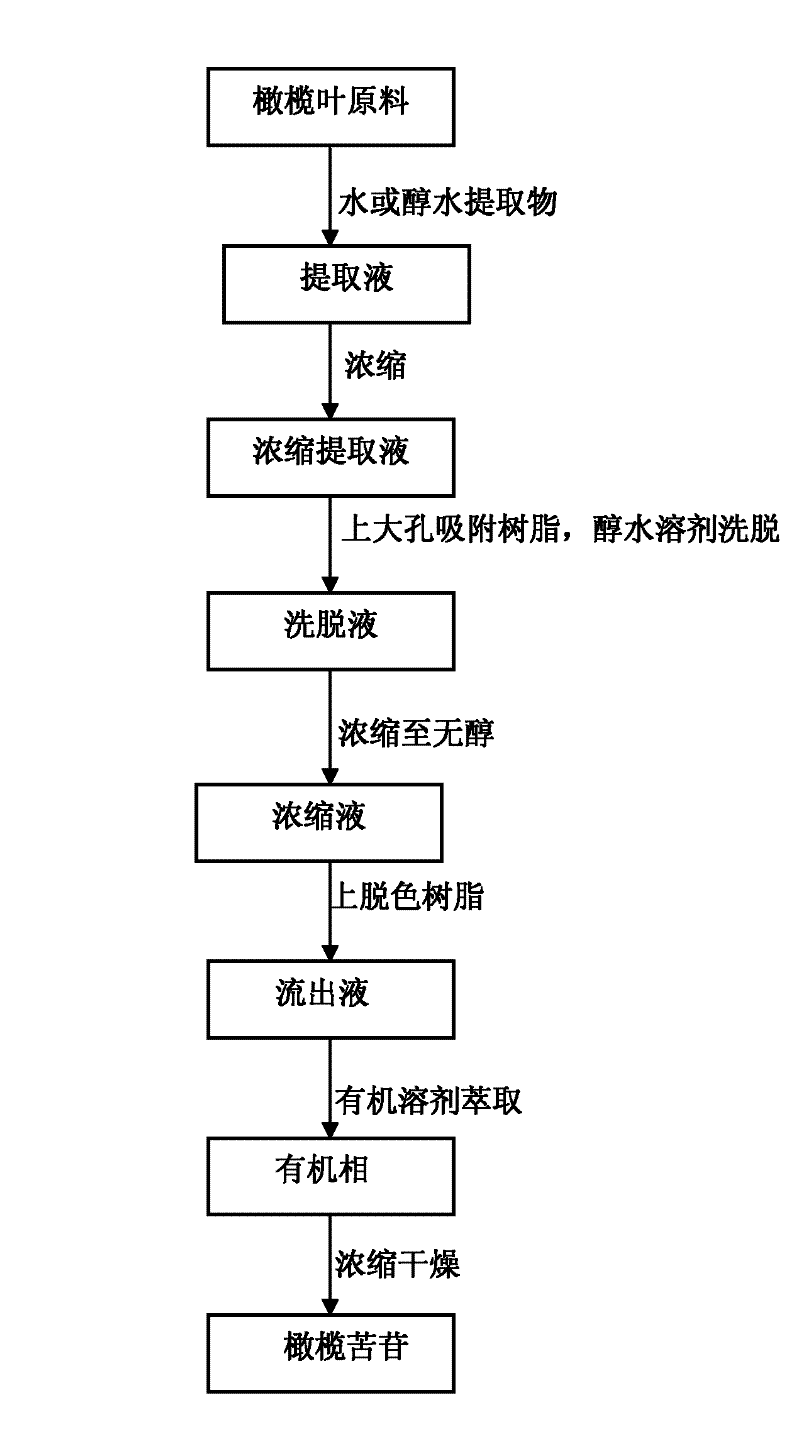

Method used

Image

Examples

Embodiment 1

[0026] Crush 100g of cleaned olive leaves, add 1000ml of water, heat and extract at 60°C for 1 hour, filter, and collect the filtrate; add 1000ml of water to the olive leaves and heat and extract again, extract three times under the same conditions, combine the filtrate and concentrate to 600ml ;

[0027] After cooling to room temperature, the concentrated extract was loaded on the macroporous adsorption resin DM130, eluted with 50% methanol (volume ratio), and the eluate was collected;

[0028] Concentrate the collected eluent (liquid A) under reduced pressure to remove methanol, concentrate to no alcohol, let it cool down to room temperature, apply the concentrated solution to the decolorization resin XDA-7, and collect all the effluent (liquid B);

[0029] Extract with n-butanol of 1 times the volume of the effluent (liquid B), collect the organic phase, concentrate and dry to remove the organic solvent, and obtain 1.52 g of the extract.

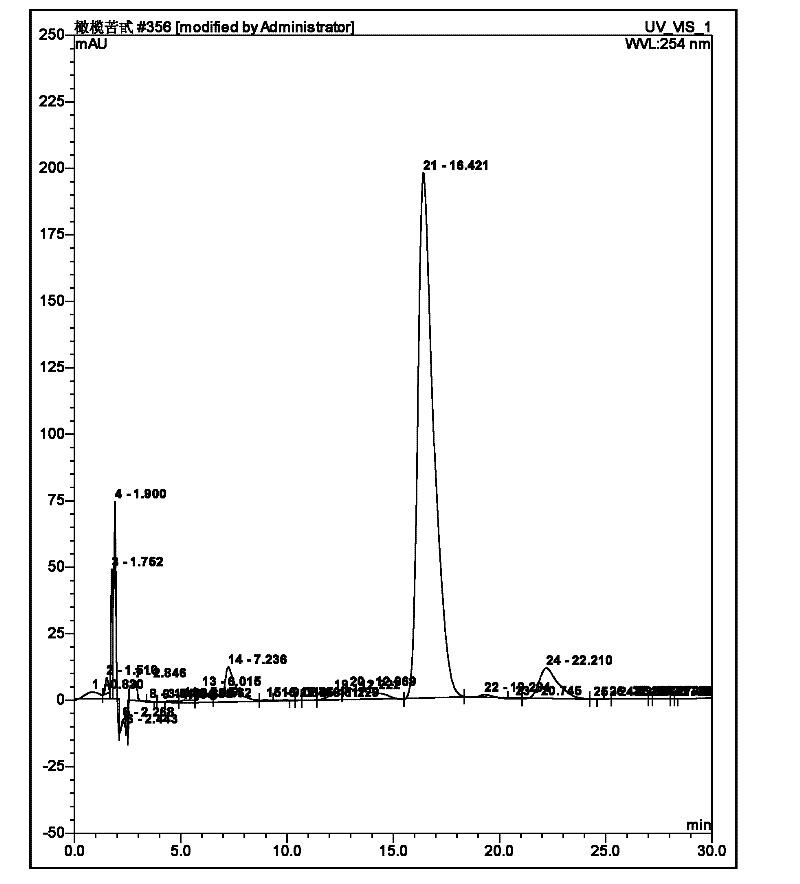

[0030] Use HPLC method to detect ...

Embodiment 2

[0032] After crushing 100g of dried olive leaves, add 2000ml of 80% ethanol, heat and reflux for extraction for 1h, filter, and collect the filtrate; extract three times in total, combine the filtrate to concentrate to no alcohol, add water to 800ml, let cool to room temperature, and load the sample on the macropore Adsorbed resin DM130, eluted with 70% ethanol, and collected the eluate (solution A);

[0033] Concentrate the collected eluent (liquid A) under reduced pressure to remove ethanol, concentrate to no alcohol, let it cool down to room temperature, apply the concentrated solution to decolorizing resin LX-68, and collect the effluent (liquid B);

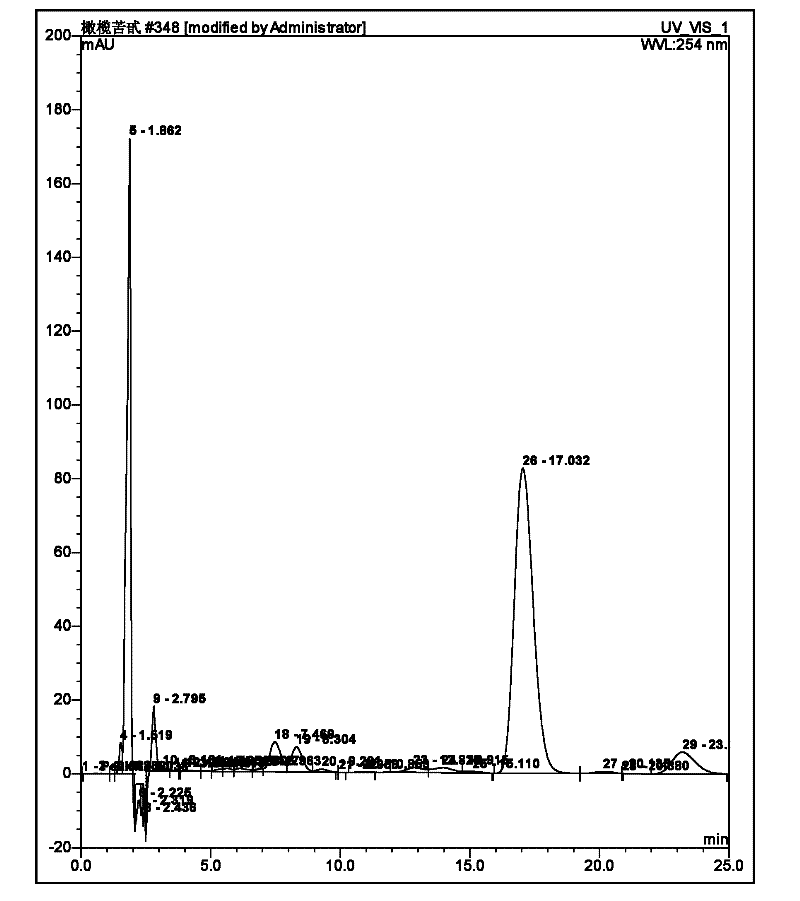

[0034] Extract with ethyl acetate of 0.8 times the volume of the effluent (liquid B), collect the organic phase (ethyl acetate phase), concentrate and dry to remove the organic solvent, obtain 1.21 g of the extract, and detect the content of oleuropein in the extract was 75.46%.

Embodiment 3

[0036] After crushing 100g of cleaned olive leaves, add 5000ml of 20% methanol, heat and reflux for extraction for 1h, filter, and collect the filtrate; extract three times in total, combine the filtrate and concentrate to 1000ml, let it cool to room temperature, and load it on macroporous adsorption resin D101 , eluted with 20% methanol, and collected the eluate (solution A);

[0037] Concentrate the collected eluate (liquid A) under reduced pressure to remove methanol, concentrate to no alcohol, let it cool down to room temperature, apply the concentrated solution to the decolorization resin LX-10G, and collect the effluent (liquid B);

[0038] Extract with ethyl acetate of 1.0 times the volume of the effluent (liquid B), collect the organic phase (ethyl acetate phase), concentrate and dry to remove the organic solvent, obtain 0.54 g of the extract, and detect the content of oleuropein in the extract is 93.22%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com