Method for preparing ethylene-trifluorochlor oethylene copolymer porous membrane

A technology of chlorotrifluoroethylene and copolymer, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as poor mechanical properties and low porosity, and achieve high mechanical strength, high porosity, The effect of broadening the range of concentration selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

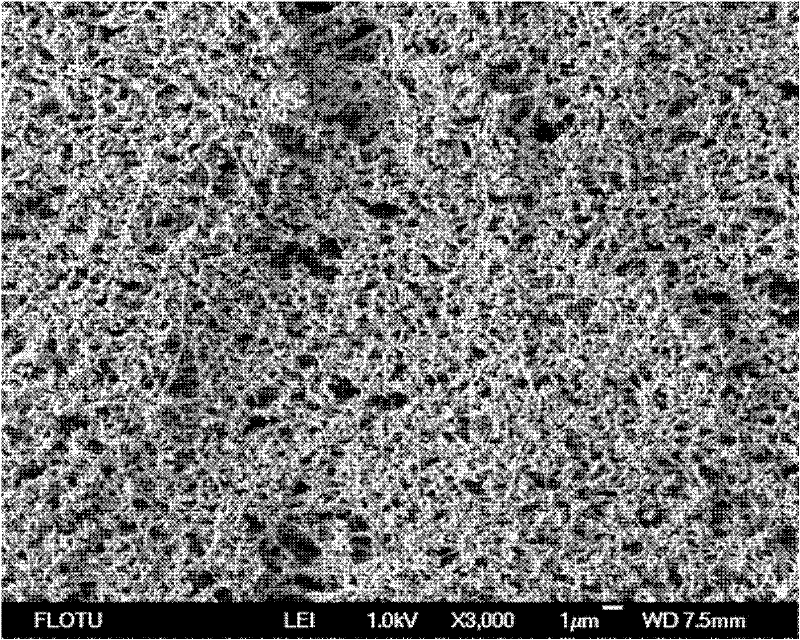

[0036] With ethylene-chlorotrifluoroethylene copolymer and diethyl phthalate, its component is that the mass percentage composition of ethylene-trifluoroethylene copolymer is 10wt%, and the mass percentage composition of diethyl phthalate is 90 wt%, put it into a high-temperature stirred tank and heat up to 240 degrees Celsius, stir and mix evenly to form a polymer homogeneous solution, and let it stand for 24 hours. Then the polymer homogeneous solution was directly hang-coated on the support net to form a flat film with a film thickness of 200 μm, and entered into a cooling liquid bath at 30°C to separate and solidify the solution into a film. The cooling liquid was a water bath. The cured flat film was extracted with ethanol and dried.

[0037]The cross-section of the membrane is a uniform sponge-like structure with a porosity of 84% and a breaking strength of 3.25MPa.

Embodiment 2

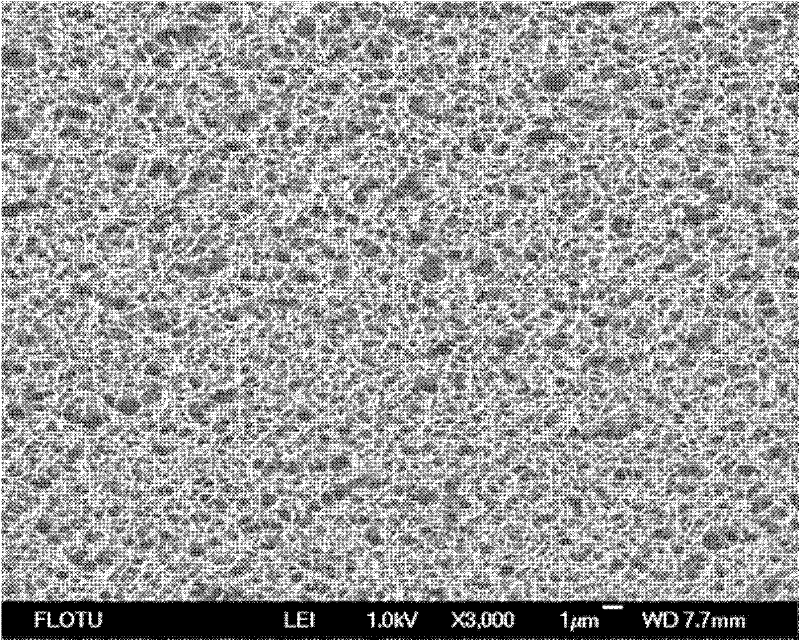

[0039] With ethylene-chlorotrifluoroethylene copolymer and diethyl phthalate, its component is that the mass percent composition of ethylene-trifluoroethylene copolymer is 28wt%, and the mass percent composition of diethylphthalate is 72 wt%, put it into a high-temperature stirred tank and heat up to 240 degrees Celsius, stir and mix evenly to form a polymer homogeneous solution, and let it stand for 24 hours. Then the polymer homogeneous solution was directly hang-coated on the support net to form a flat film with a film thickness of 200 μm, and entered into a cooling liquid bath at 30°C to solidify the solution into a film by phase separation. The cooling liquid was a glycerol bath. The cured flat film was extracted with ethanol and dried.

[0040] The cross-section of the membrane is a uniform sponge-like structure with a porosity of 71% and a breaking strength of 10.58MPa.

Embodiment 3

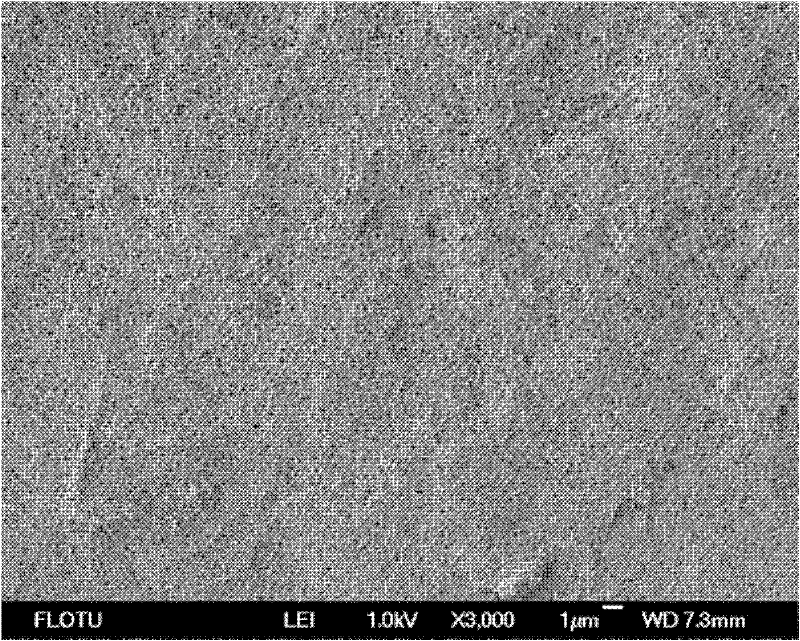

[0042] With ethylene-chlorotrifluoroethylene copolymer and diethyl phthalate, its component is that the mass percent composition of ethylene-trifluoroethylene copolymer is 60wt%, and the mass percent composition of diethylphthalate is 40 wt%, put it into a high-temperature stirred tank and heat up to 250 degrees Celsius, stir and mix evenly to form a polymer homogeneous solution, and let it stand for 24 hours. Then the polymer homogeneous solution was directly hang-coated on the support net to form a flat film with a film thickness of 200 μm, and entered into a cooling liquid bath at 30°C to separate and solidify the solution into a film. The cooling liquid was a water bath. The cured flat film was extracted with ethanol and dried.

[0043] The cross-section of the membrane is a uniform sponge-like structure with a porosity of 31% and a breaking strength of 14.59MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com