Catalyst for gas phase hydrogenation of acetic acid to prepare ethanol

A technology for preparing ethanol and catalysts, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, organic chemistry, etc., to reduce energy consumption and improve selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

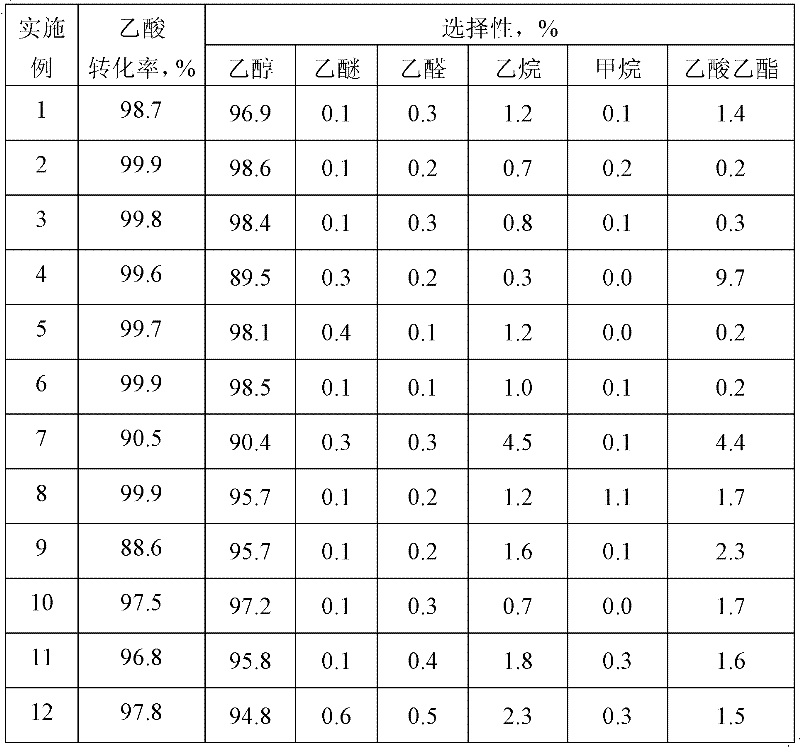

Examples

Embodiment 1

[0027] The catalyst of embodiment 1 is 10%Mo-5%Re-1.0%Ru / almond kernel carbon. Prepared by conventional impregnation method: take 8.40 grams of apricot kernel charcoal (20-40 mesh), soak and boil in 3%wt nitric acid for 4 hours before use, wash with distilled water to about pH=7.0, dry at 120°C for 6 hours, and configure 15ml contains 1.8971 grams (NH 4 ) 2 Mo 2 o 4 .4H 2 O, 0.7203 g NH 4 ReO 4 and 0.1996 g RuCl 3 .3H 2 O aqueous solution, air-dried naturally, and oven-dried at 120°C for 4 hours. Before use, in hydrogen at 300°C (atmospheric pressure, 1000h -1 ) reduction activation for 5 hours.

Embodiment 2

[0029] Catalyst 10%W-5.0%Re-1.0%Ru / almond charcoal of embodiment 2. In addition to the configuration 15ml contains 1.5443 grams (NH 4 ) 2 WO 4 Except aqueous solution, all the other preparation steps are identical with embodiment 1.

Embodiment 3

[0031] Catalyst of Example 3 10%W-5.0%Re-1.0%Ru / coir charcoal. Except weighing 8.40 grams of coconut shell charcoal, all the other preparation steps are the same as in Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com