Composite structure high barrier molded resin sheet material, and processing method thereof

A resin molding and composite structure technology, applied in synthetic resin layered products, chemical instruments and methods, layered products, etc., can solve the problems of poor barrier properties, product packaging with difficult barrier requirements, and achieve cost optimization and environmental protection optimization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

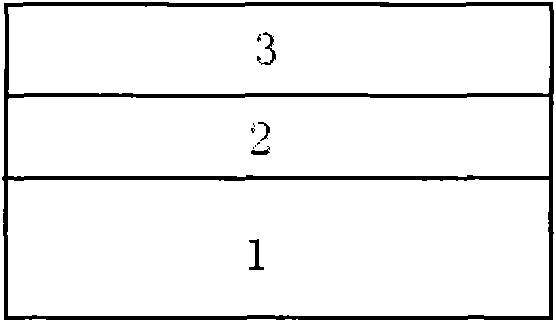

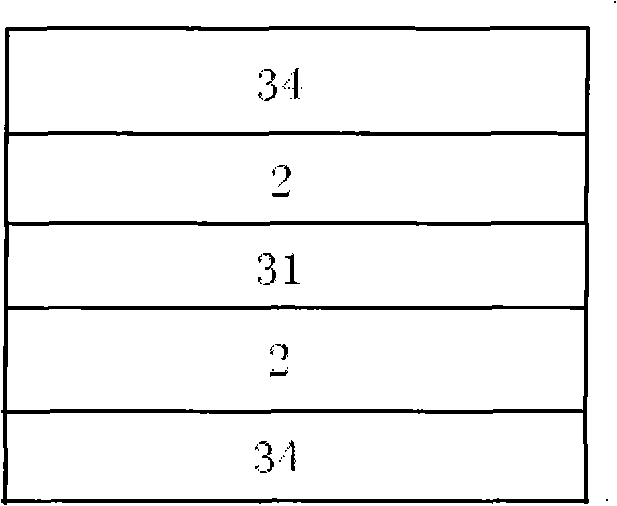

[0027] like Figure 2-4 As shown, the forming outer film layer 1 is a polyethylene terephthalate (PET) sheet of 300 μm, and the inner film layer 3 of 5 layers is a polyethylene layer 32 / adhesive layer 2 / polyethylene layer of 100 μm co-extruded film. Dichloroethylene layer 31 / adhesive layer 2 / polyethylene layer 32 structure, after the adhesive layer 2 is compounded with a retort-resistant two-component polyurethane adhesive, a co-extruded nylon film is used as a cover film. Uses: After molding, it is packaged and sterilized at 120 degrees Celsius, then stored at room temperature, and the shelf life can reach more than 60 days.

[0028] Since polyvinylidene chloride has excellent barrier properties, it is made into a composite sheet with polyethylene terephthalate through a dry composite process, which improves the barrier properties of the sheet. Under the same thickness, the flexibility of the sheet is improved, and multi-functionality, saving, environmental protection and co...

Embodiment 2

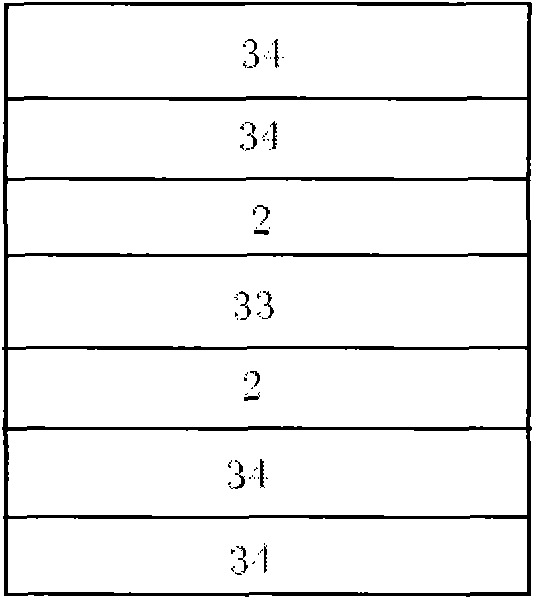

[0031] like Figure 2-5 As shown, the forming outer film layer 1 is a 400 μm polypropylene (PP) sheet, and the inner film layer 3 is a 9-layer co-extruded film and is a 150 μm polypropylene layer 34 / polypropylene layer 34 / polypropylene layer 34 / adhesive The structure of knot layer 2 / nylon layer 33 / adhesive layer 2 / polypropylene layer 34 / polypropylene layer 34 / polypropylene layer 34 is compounded by a two-component polyurethane adhesive that is resistant to cooking after the adhesive layer 2. The co-extrusion film of polyvinylidene chloride is used as the cover film. Uses: After molding, it is packaged and sterilized at 135 degrees Celsius and stored at room temperature. The shelf life can reach more than 90 days.

[0032] Because nylon has good barrier properties, it is made into a composite sheet with polyethylene terephthalate through a dry composite process, which improves the barrier properties of the sheet. Under the same thickness, the flexibility of the sheet is impro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com