Production process of glass fiber reinforced plastic paint

A fiberglass and coating technology, applied in the direction of coating, etc., can solve the problems of coating layer falling off, affecting service life and appearance, poor adhesion, etc., and achieve the effect of strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

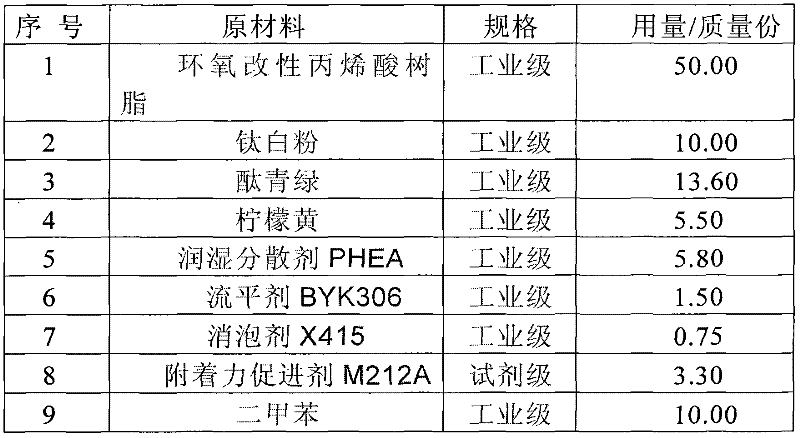

[0005] In order to make the FRP paint have good adhesion, the present invention has successfully developed a paint base material with superior adhesion, namely epoxy-modified acrylic resin, and the required colored paint can be obtained by adding the required pigments to the base material. The paint is sprayed onto the surface of the glass product to obtain a highly adherent coating with color.

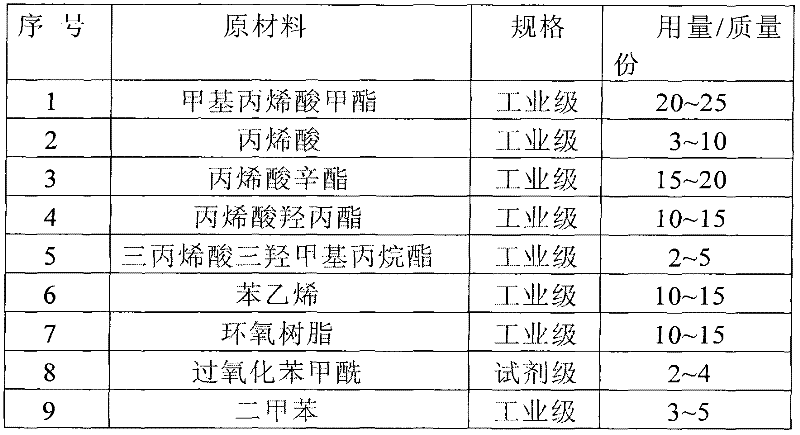

[0006] The formula and proportioning table for preparing epoxy-modified acrylic resin are as follows:

[0007] Epoxy modified acrylic resin production formula

[0008]

[0009] The process of preparing epoxy-modified acrylic resin: Put epoxy resin and xylene into the reaction kettle according to the ratio in the above table, start stirring and raise the temperature to 78-82°C, add acrylic acid dropwise after stirring evenly, and the dropping time is controlled at About 30min. After all the acrylic acid has been added dropwise, react for 2-2.5 hours.

[0010] Mix methyl methacryl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com