Acid leaching method for extracting potassium, aluminum and silicon elements from potassium feldspar

A technology of potassium feldspar and silicon element, applied in the field of decomposition of potassium-containing rocks, can solve the problems of high production cost, cumbersome operation steps, and low recycling rate, achieve high quality and performance, simplify processing technology, and improve ion exchange efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

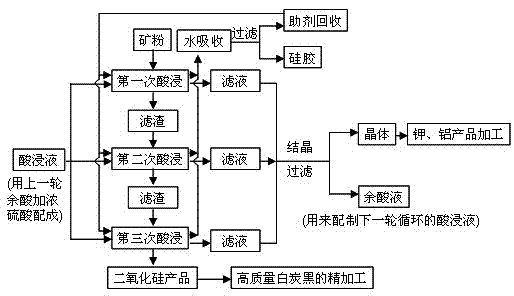

Image

Examples

Embodiment 1

[0036] An acid leaching method for extracting potassium, aluminum and silicon elements from potassium feldspar, the acid leaching method includes the following processes in sequence:

[0037] The first acid leaching process: first add potassium feldspar ore powder with a particle size of 100 mesh to the acid leaching solution, the mass ratio of potassium feldspar ore powder and acid leaching solution is 1:3.5, and then stir under normal pressure for 1– It takes 4 hours for the first acid leaching reaction. During the reaction, slowly add hydrofluoric acid while stirring. The mass ratio of potassium feldspar ore powder to hydrofluoric acid is 1:0.003–0.03, and the reaction temperature is 90°C–120°C. After the reaction, the reaction solution is filtered and separated to obtain the first acid leaching filter residue and the first acid leaching filtrate, and then the first acid leaching filtrate is sequentially cooled and crystallized, filtered and separated to obtain crystallizati...

Embodiment 2

[0044] An acid leaching method for extracting potassium, aluminum and silicon elements from potassium feldspar, the acid leaching method includes the following processes in sequence:

[0045] The first acid leaching process: first add potassium feldspar powder with a particle size of 200 mesh to the acid leaching solution, the mass ratio of potassium feldspar powder and acid leaching solution is 1:2, and the potassium feldspar powder is soaked in sulfuric acid Pretreatment of iron removal process, and then stirring under normal pressure for 1-4 hours to carry out the first acid leaching reaction. During the reaction, sodium fluoride is slowly added while stirring, and the mass ratio of potassium feldspar ore powder to sodium fluoride is 1. : 0.003–0.03, the reaction temperature is 90°C–120°C, after the reaction, the reaction solution is filtered and separated to obtain the first acid leaching filter residue and the first acid leaching filtrate, and then the first acid leaching ...

Embodiment 3

[0052] An acid leaching method for extracting potassium, aluminum and silicon elements from potassium feldspar, the acid leaching method includes the following processes in sequence:

[0053] The first acid leaching process: first add potassium feldspar powder with a particle size of 300 mesh to the acid leaching solution, the mass ratio of potassium feldspar powder and acid leaching solution is 1:3, and the potassium feldspar powder is magnetically separated Pretreatment of iron removal process, and then stirring under normal pressure for 1-4 hours to carry out the first acid leaching reaction. During the reaction, potassium fluoride is slowly added while stirring, and the mass ratio of potassium feldspar ore powder to potassium fluoride is 1 : 0.003–0.03, the reaction temperature is 90°C–120°C, after the reaction, the reaction solution is filtered and separated to obtain the first acid leaching filter residue and the first acid leaching filtrate, and then the first acid leach...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com