Engine electric control auxiliary cooling system freeing from engine rotational speed influence

An auxiliary cooling system, engine speed technology, applied in the direction of engine cooling, engine components, machines/engines, etc., can solve the problems of increased engine fuel consumption, limited flow capacity, low engine operating temperature, etc., to overcome the limited flow capacity, Easy to popularize and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

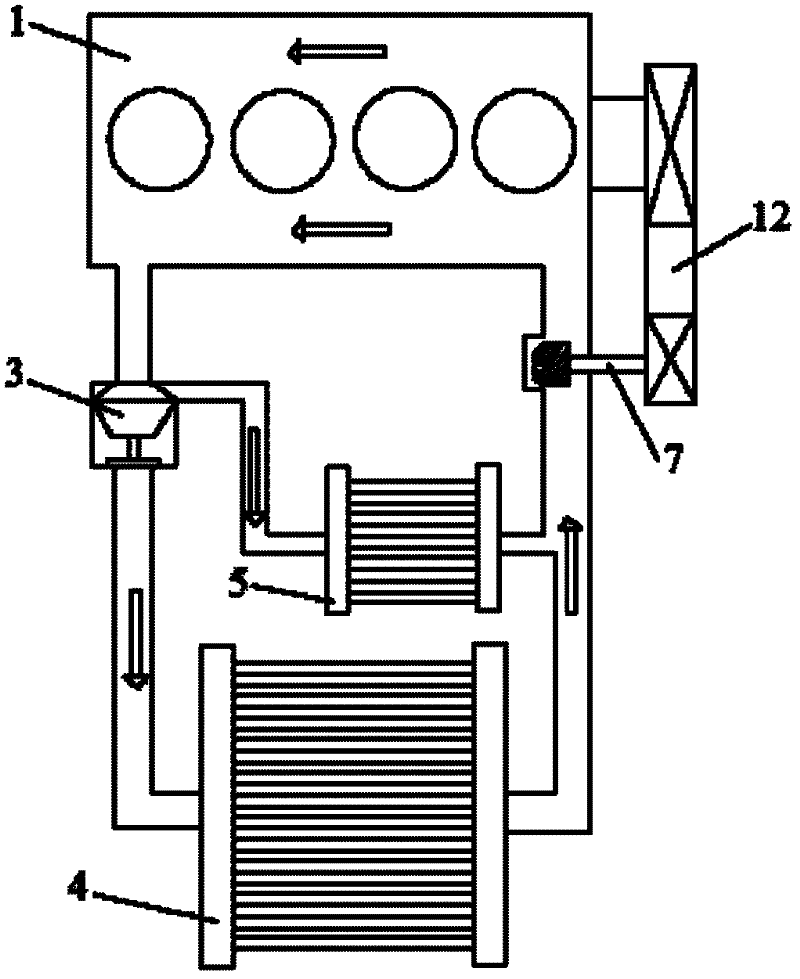

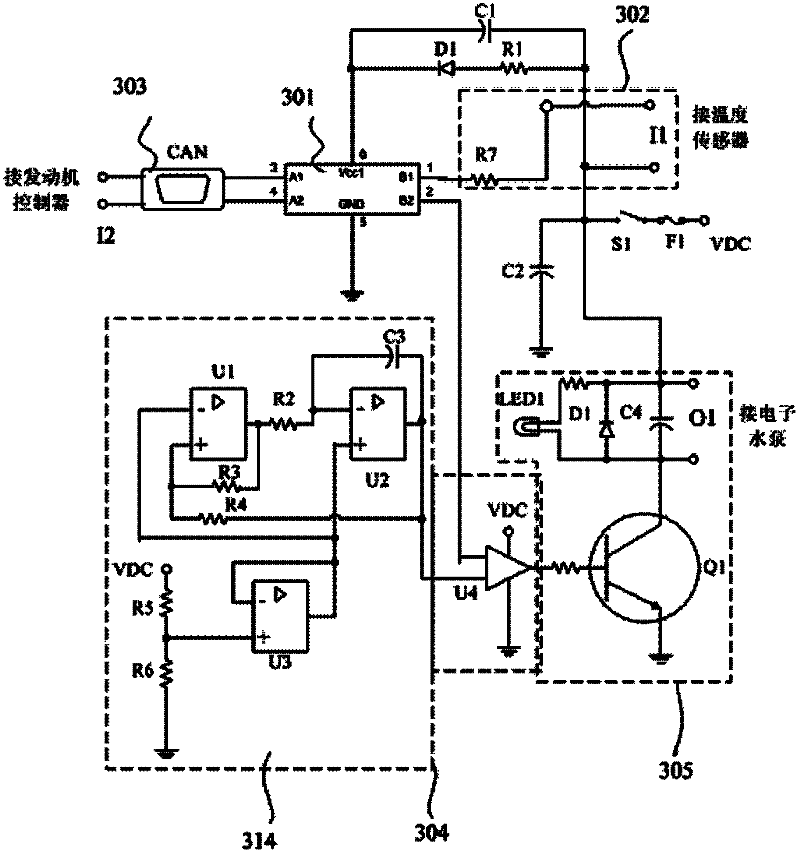

Embodiment approach 1

[0035]When the engine is cold started, the temperature of the engine 1 is relatively low, and it takes a certain time to reach the normal temperature. At this stage, the mechanical water pump 7 is running with the engine 1 . When the electronic water pump controller 10 detects that the engine outlet water temperature is low through the engine coolant temperature sensor 2, and detects that the engine 1 is running through the engine controller 11, it controls the electronic water pump 8 not to operate, and the main valve of the thermostat 3 is closed. state; under the action of the coolant pressure difference, the second one-way valve 9 at the outlet of the electronic water pump is closed, and the first one-way valve 6 at the inlet of the mechanical water pump is fully opened; the coolant pressurized by the mechanical water pump 7 flows through the engine 1 respectively , 3 secondary valves of the thermostat and the warm air core 5 get back to the 7 inlets of the mechanical wate...

Embodiment approach 2

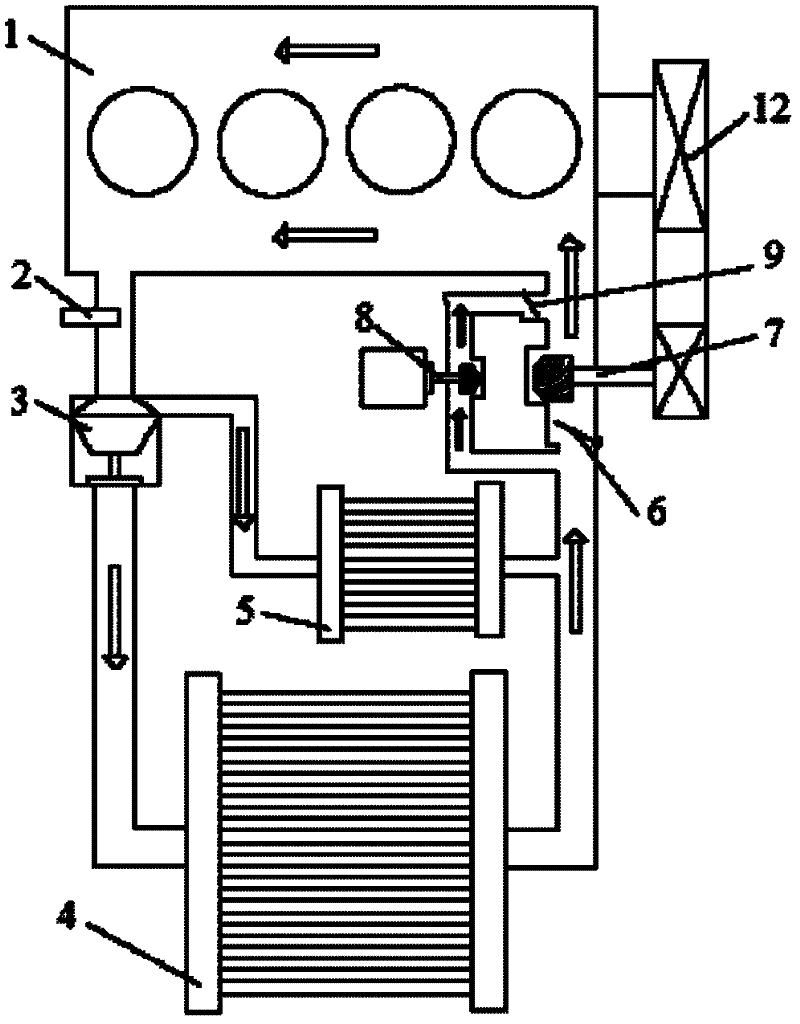

[0037] After the engine is warmed up, the mechanical water pump 7 runs with the engine 1. When the coolant temperature at the engine outlet reaches temperature B, the main valve of the thermostat 3 is opened, and part of the coolant flows through the radiator 4, and the other part of the coolant flows through the heater core. child 5. As the temperature rises, when the electronic water pump controller 10 detects that the engine outlet water temperature exceeds the threshold temperature D through the engine coolant temperature sensor 2, and detects that the engine 1 is running through the engine controller 11, the electronic water pump 8 starts to work in the middle mode. Under the action of pressure, the second check valve 9 at the outlet of the electronic water pump opens, and the flow rate of the system coolant is equal to the sum of the flow rate of the mechanical water pump 7 and the flow rate of the electronic water pump 8 . When the electronic water pump controller 10 de...

Embodiment approach 3

[0039] When the operating temperature of the engine is high, the electronic water pump 8 works at a medium speed. When the electronic water pump controller 10 detects that the engine outlet coolant temperature rises to a threshold temperature F higher than the threshold temperature D through the engine coolant temperature sensor 2, the electronic water pump 8 starts to work at full speed, and the flow rate of the system coolant is equal to the sum of the flow rate of the mechanical water pump 7 and the flow rate of the electronic water pump 8 . When the electronic water pump controller 10 detects through the engine coolant temperature sensor 2 that the engine outlet coolant temperature drops to a threshold temperature E which is lower than the threshold temperature F but higher than the threshold temperature D, the electronic water pump 8 starts to work at a medium speed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com