Micro-fluidic cell suspension culture chip and application thereof

A cell suspension, microfluidic technology, applied in tissue cell/virus culture devices, enzymology/microbiology devices, bioreactor/fermenter combinations, etc., can solve the complex and limited chip design and processing and drive control systems The number of units, the area of the chip occupied, etc., to achieve the effect of less cross-contamination, easy control, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0085] Embodiment 1 refers to Figure 1A ~D, this embodiment is composed of a culture array distributed on a chip, the array includes 4 culture units 100 connected in series on a plane, and each culture unit includes a culture channel 111 on the first layer and a culture channel 111 on the first layer. The cultivation channel 121 of the second layer, the two ends of the two sections of the cultivation channel are connected to each other, forming a closed loop that is viewed as a rectangle when viewed from above. The thickness of the first layer 110 of the chip is 1.5 mm. micron, 3 cm long; the second layer 120 of the chip is 10 micron thick, and the culture channel 121 of the second layer is 100 micron wide, 10 micron deep, and 3 cm long; each culture unit has an independent liquid inlet 113 and a liquid outlet 123, with a diameter of 2 mm, used for the injection and discharge of liquid and culture; the shape and size of each culture unit 100 are consistent, and they are arrang...

Embodiment 2

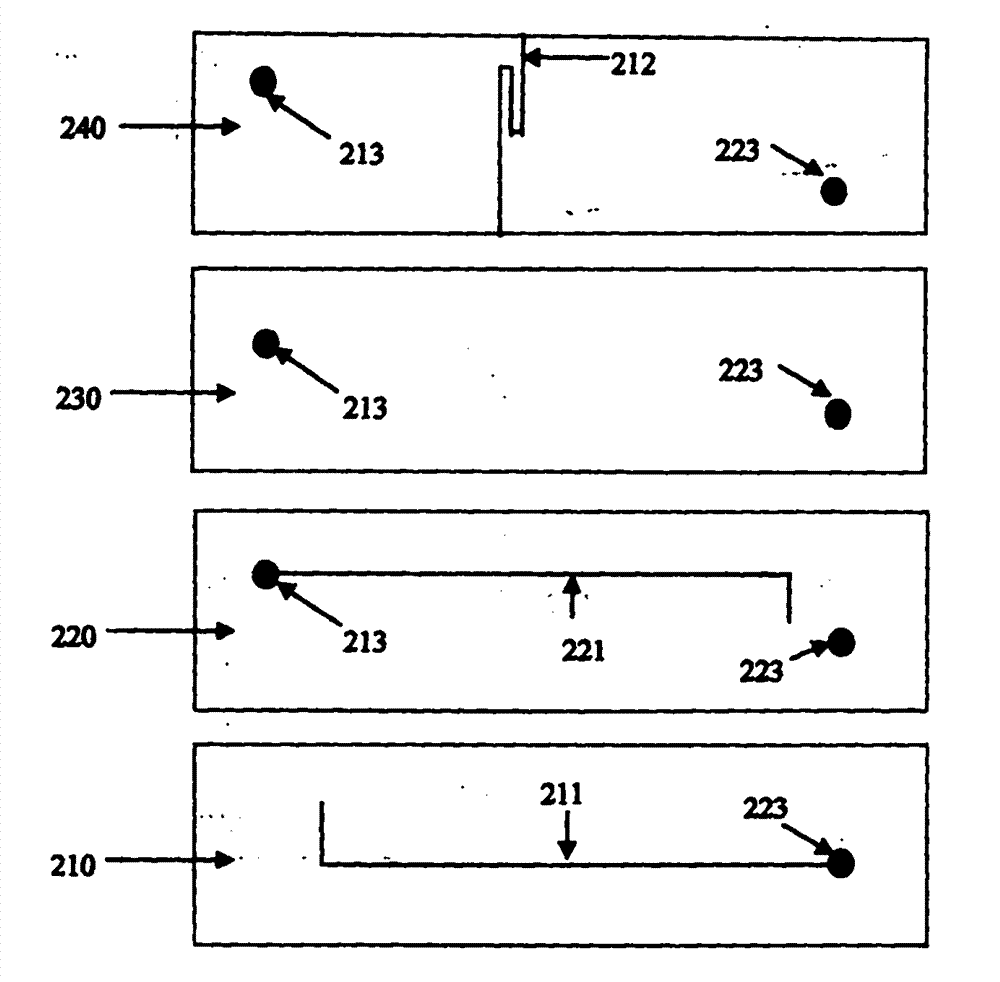

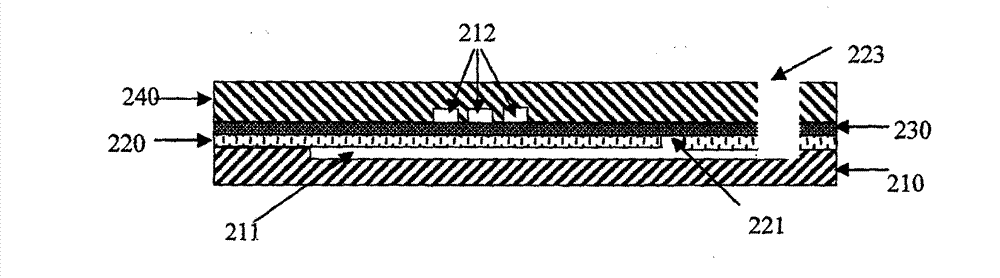

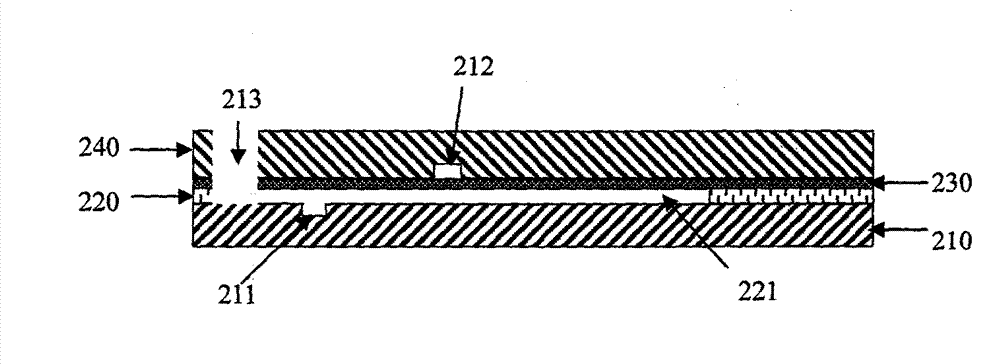

[0086] Embodiment 2 refers to Figure 2A~D, this embodiment is composed of a culture array distributed on a chip, the array includes 4 culture units 200 connected in series on a plane, each culture unit 200 includes a culture channel 211 on the first layer and The cultivation channel 221 of the second layer, the two ends of the two sections of the cultivation channel are connected to each other, forming a closed loop viewed as a rectangle when viewed from above. 10 microns, 3 cm long; the second layer 220 of the chip is 10 microns thick, and the culture channel 221 of the second layer is 100 microns wide, 10 microns deep, and 3 cm long; each culture unit 200 has an independent liquid inlet 213 and outlet Liquid port 223, diameter is 2 millimeters, is used for the injection and discharge of liquid and culture; The shape and size of each culture unit 200 are all consistent, arrange in a row; The upper part of the channel is the third layer 230, this layer is a A layer of elasti...

Embodiment 3

[0087] Embodiment 3 refers to Figure 3A ~D, this embodiment is composed of a culture array distributed on a chip, the array includes 4 culture units 300 connected in series on a plane, each culture unit 300 includes a culture channel 311 on the first layer, The cultivation channel 321 of the second layer, the cultivation channel 331 of the third layer, the cultivation channel 341 of the fourth layer, and the cultivation channel 351 of the fifth layer, the two ends of these cultivation channels are connected successively, forming a rectangular shape viewed from above. Closed circuit, the thickness of the first layer 310 of the chip is 1.5 mm, the culture channel 311 of the first layer is 100 microns wide, 10 microns deep, and 3 cm long; the second layer 320 of the chip, the third layer 330 of the chip, the fourth layer 340 of the chip, The fifth layer 350 of the chip and the sixth layer 360 of the chip both have a thickness of 10 microns, and the cultivation channel 321 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com