High heat radiation LED (Light Emitting Diode) nonmetal substrate and high heat radiation LED element as well as making method thereof

A non-metallic plate and non-metallic technology, which is applied in the field of LED non-metallic substrate manufacturing method, can solve the problems of inability to apply LED chip packaging, reduced area of bonding die pad, small precision, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

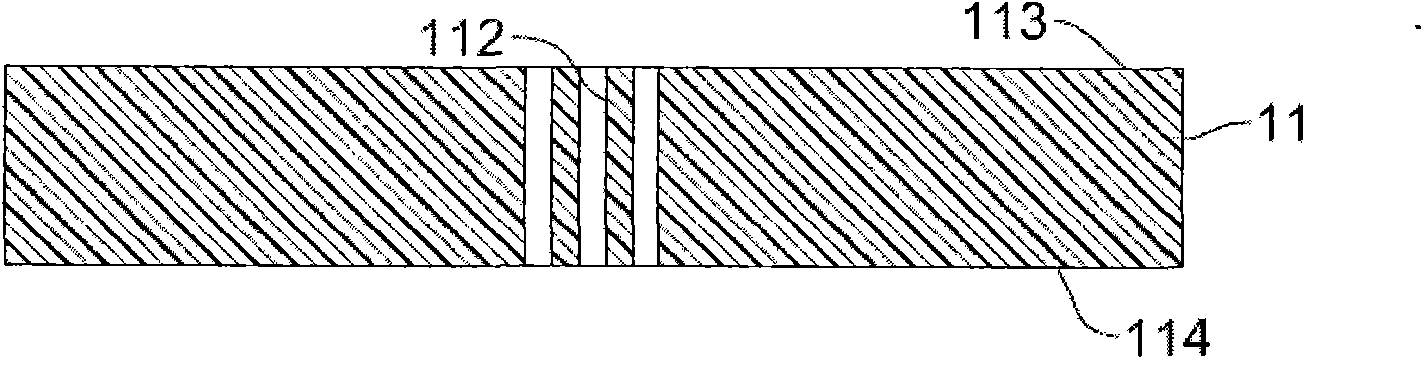

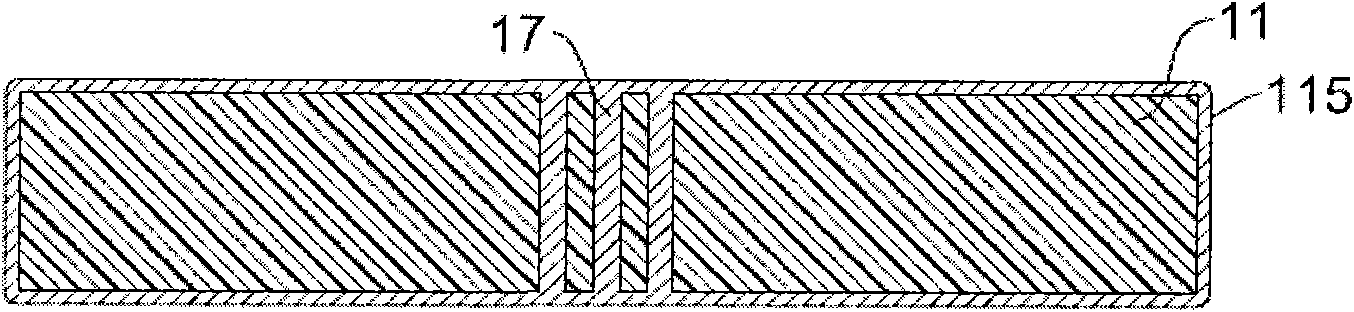

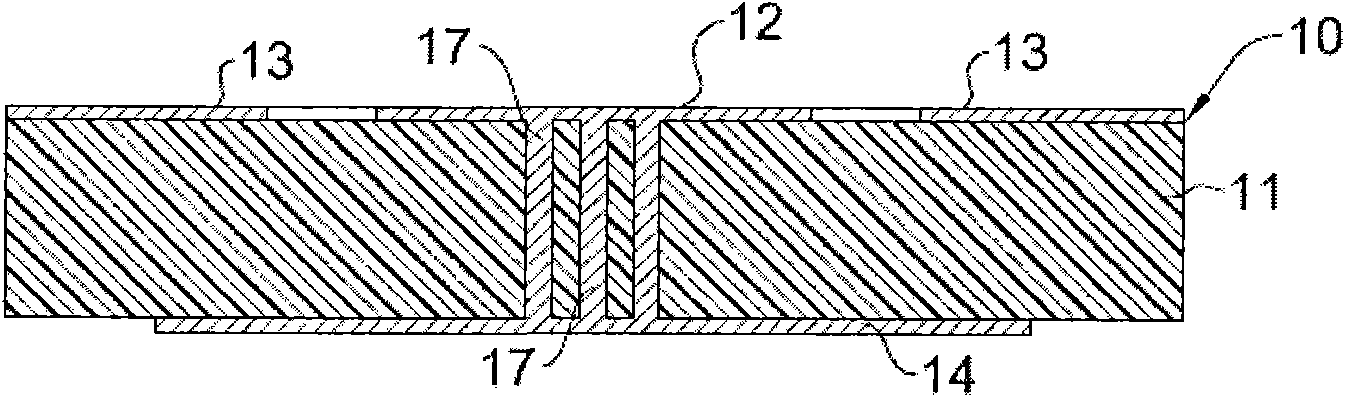

[0052] See first Figures 1A to 1EAs shown, it is a production flow chart of the first preferred embodiment of a high heat dissipation LED element of the present invention. In this embodiment, the high heat dissipation LED element is used to be welded on the heat dissipation module 40, as Figure 8A As shown, it contains:

[0053] Provide a non-metallic plate body 11; in this embodiment, the non-metallic plate body 11 is a ceramic plate body, also can be a silicon substrate, its thickness is 0.3mm to 2mm;

[0054] At least one second through hole 112 is formed on the non-metallic plate body 11; in this embodiment, each second through hole 112 is formed by laser drilling or other drilling processing methods, and its diameter is more than 0.02 mm;

[0055] Electroplating the outer surface of the non-metal plate body 11 and each second through hole 112, and forming an electroplated copper layer 115 on the outer surface, and forming a solid thermally conductive copper column 17 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com