Method for manufacturing steel-based particle reinforced composite anti-wear piece

A composite material anti-wear and particle-enhancing technology is applied in the field of preparation of steel-based particle-reinforced anti-wear parts, which can solve the problems of high cost, low interface bonding strength, low density, etc. production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

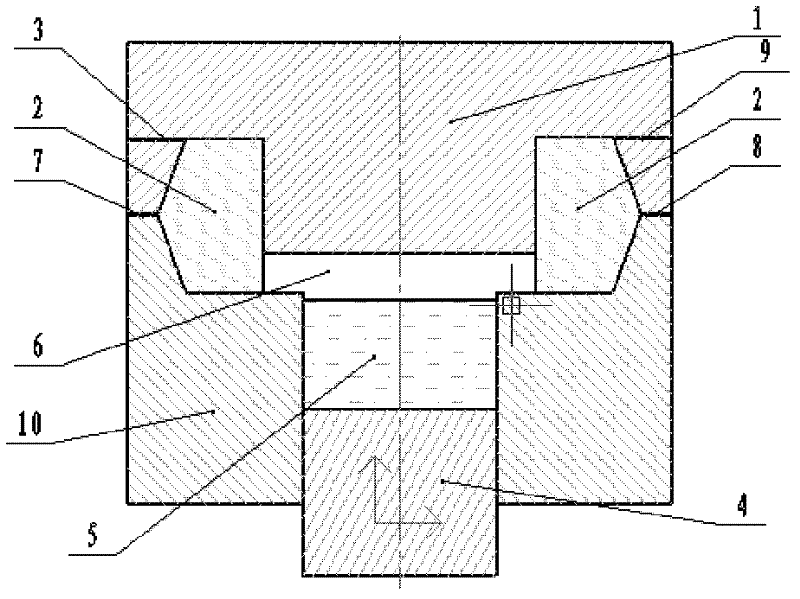

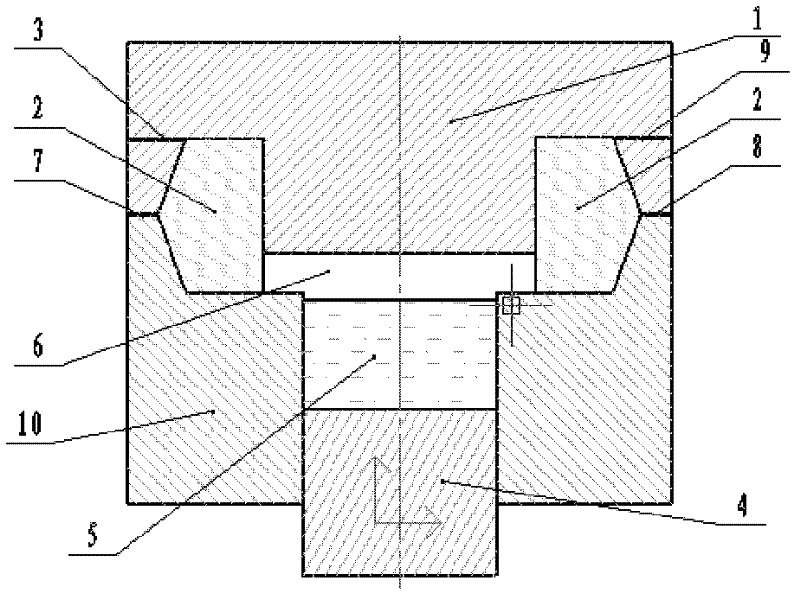

Image

Examples

Embodiment approach 1

[0033] A method for manufacturing a steel-based particle-reinforced composite wear-resistant part, the method comprising the following steps:

[0034] Step 1: Material preparation and pretreatment

[0035] Polystyrene is selected as the carrier material; ethyl acetate solution is used as the organic solvent; titanium carbide is used as the reinforcing particle, and the particle size is 10nm;

[0036] Mix polystyrene and ethyl acetate solutions with a volume ratio of 10:1 to make a viscous fluid carrier;

[0037] Nickel-plated surface pretreatment on titanium carbide;

[0038] Step 2: Prepare the prefab

[0039] Add the titanium carbide reinforced particles that account for 5% of the viscous fluid carrier and have undergone surface pretreatment in step 1 into the viscous fluid carrier, and stir evenly to form a viscous fluid carrier with titanium carbide reinforced particles, and add titanium carbide reinforced particles The viscous fluid carrier is injected into the mold ca...

Embodiment approach 2

[0047] A method for manufacturing a steel-based particle-reinforced composite wear-resistant part, the method comprising the following steps:

[0048] Step 1: Material preparation and pretreatment

[0049] Polystyrene is selected as the carrier material; ethyl acetate solution is used as the organic solvent; titanium carbide is used as the reinforcing particle with a particle size of 10 μm;

[0050] Mix polystyrene and ethyl acetate solutions with a volume ratio of 25:1 to make a viscous fluid carrier;

[0051] Nickel-plated surface pretreatment on titanium carbide;

[0052] Step 2: Prepare the prefab

[0053] Add the titanium carbide reinforced particles that account for 25% of the viscous carrier and have undergone surface pretreatment in step 1 into the viscous carrier, and stir evenly to form a viscous carrier with reinforced particles, and viscous flow of the attached titanium carbide particles The state carrier is injected into the prefabricated body mold cavity whose...

Embodiment approach 3

[0061] A method for manufacturing a steel-based particle-reinforced composite wear-resistant part, the method comprising the following steps:

[0062] Step 1: Material preparation and pretreatment

[0063] Polymethyl methacrylate-styrene copolymer resin is selected as the carrier material; acetone solution is used as the organic solvent; tungsten carbide is used as the reinforcing particle, and the particle size is 30 μm;

[0064] Mix polymethyl methacrylate-styrene copolymer resin and acetone solution with a volume ratio of 10:1 to make a viscous fluid carrier;

[0065] Cobalt-plated surface pretreatment of tungsten carbide;

[0066] Step 2: Prepare the prefab

[0067] Add the tungsten carbide reinforced particles that account for 15% of the viscous fluid carrier and have undergone surface pretreatment in step 1 into the viscous fluid carrier, and stir evenly to form a viscous fluid carrier with tungsten carbide reinforced particles, and add the tungsten carbide reinforced ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com