Method for producing long-acting compound fertilizer by utilizing waste resources

A technology of waste resources and compound fertilizer, applied in the field of long-term compound fertilizer production, can solve the problems of inability to keep up, high cost, difficult to accumulate and use, etc., and achieve the effect of low cost, promoting grain particles and good fertilizer efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: in terms of producing 500kg compound fertilizer:

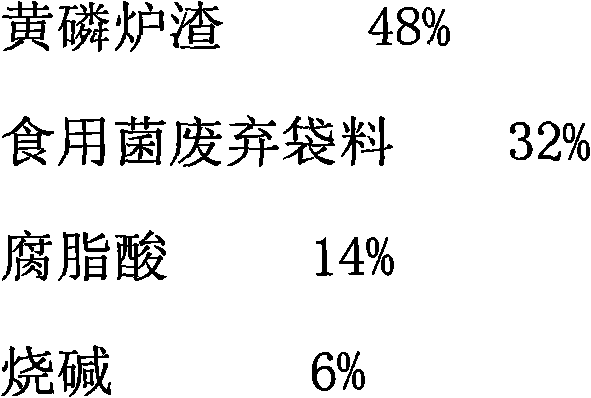

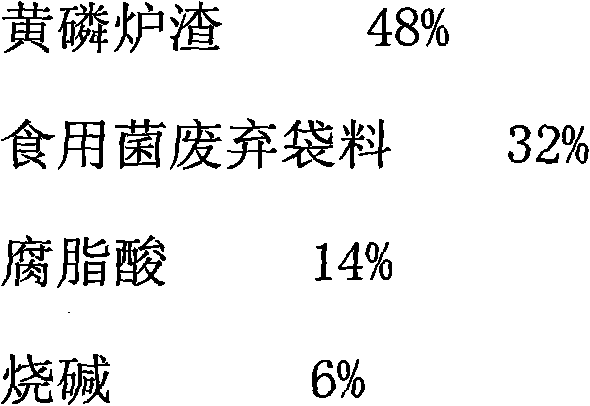

[0019] 1) The weight of the required raw material formula is calculated as a percentage of dry material as follows:

[0020] Refined yellow phosphorus slag 48% 240kg, edible mushroom waste bag 32% 160kg, humic acid 14% 70kg, caustic soda 6% 30kg,

[0021] Two) preparation method is as follows:

[0022] 1) Put the yellow phosphorus slag into a ball mill according to the formula components and grind it to 200 mesh for use; 2) Use a pulverizer to pulverize the waste edible fungus bag material according to the weight of the components to 100 mesh for use; 3) Put the humic acid and After the caustic soda is mixed according to the measurement, add water with twice the total weight of the mixture, stir evenly, heat to 95°C, and form a paste after 2 hours; 4) Mix the materials processed in the above 1), 2) and 3) together Put it into a mixer and stir evenly; 5) Put the evenly stirred material into a pelletizing ...

Embodiment 2

[0023] Embodiment 2: in terms of producing 1000kg compound fertilizer:

[0024] 1) The weight of the required raw material formula is calculated as a percentage of dry material as follows:

[0025] Refined yellow phosphorus slag 48% 480kg, edible mushroom waste bag 32% 320kg, humic acid 14% 140kg, caustic soda 6% 60kg,

[0026] Two) preparation method is as follows:

[0027] 1) Put the yellow phosphorus slag into a ball mill according to the formula components and grind it to 200 mesh for use; 2) Use a pulverizer to pulverize the waste edible fungus bag material according to the weight of the components to 100 mesh for use; 3) Put the humic acid and After the caustic soda is mixed according to the measurement, add water with twice the total weight of the mixture, stir evenly, heat to 95°C, and form a paste after 2 hours; 4) Mix the materials processed in the above 1), 2) and 3) together Put it into a mixer and stir evenly; 5) Put the evenly stirred material into a pelletizin...

Embodiment 3

[0028] Embodiment 3: in terms of producing 2000kg compound fertilizer:

[0029] 1) The weight of the required raw material formula is calculated as a percentage of dry material as follows:

[0030] Refined yellow phosphorus slag 48% is 960kg, edible mushroom waste bag material 32% is 640kg, humic acid 14% is 280kg, caustic soda 6% is 120kg,

[0031] Two) preparation method is as follows:

[0032] 1) Put the yellow phosphorus slag into a ball mill according to the formula components and grind it to 200 mesh for use; 2) Use a pulverizer to pulverize the waste edible fungus bag material according to the weight of the components to 100 mesh for use; 3) Put the humic acid and After the caustic soda is mixed according to the measurement, add water with twice the total weight of the mixture, stir evenly, heat to 95°C, and form a paste after 2 hours; 4) Mix the materials processed in the above 1), 2) and 3) together Put it into a mixer and stir evenly; 5) Put the evenly stirred mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com