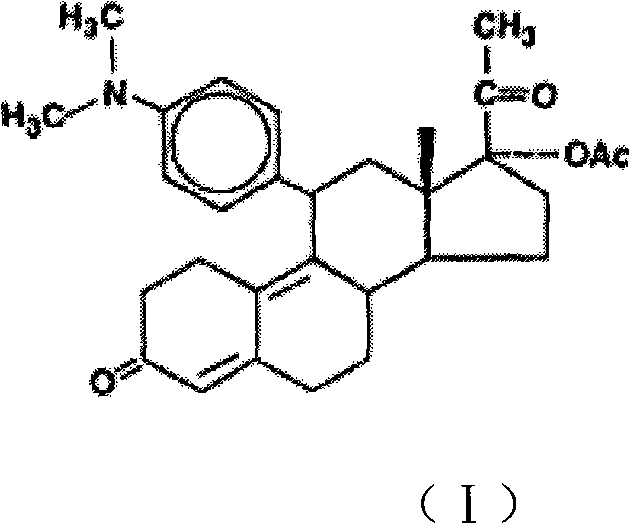

Method for purifying ulipristal serving as synthetic progesterone receptor regulator

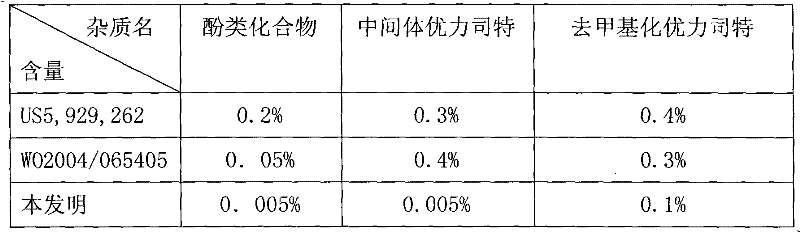

A purification method, a Uliplast-style technology, applied in the field of progesterone receptor modulator Uliplast acetate, which can solve the problem that the purity of the final product is difficult to control, the intermediates Uliplast and demethylated Ulipast Extraordinary residues and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] 1) 40 g of the crude product of uliplast acetate was concentrated and dried with 60 g of silica gel (1.5 times) for sample loading, passed over 800 g of silica gel (200-300 mesh silica gel, 20 times the weight consumption), and dichloromethane: acetone = 20:1 After elution, the product was collected and concentrated to dryness to obtain 35 g of the desired product.

[0016] 2) After concentrating to dryness, 35 g of uliplast acetate was dissolved in 105 ml of ethyl acetate, 315 ml of petroleum ether was added, and stirred for one hour. Then filter. The solid was washed twice with 50 ml of a mixed solution of petroleum ether: ethyl acetate = 5:1. Dry under reduced pressure. 32 g of white solid powder were obtained.

[0017] 3) Dissolve 32 grams of white solid powder in 300ml of absolute ethanol, add 360ml of water under reflux conditions under controlled temperature (70~75°C), and let stand to cool down to room temperature. The crystals were filtered and dried under ...

Embodiment 2

[0019] 1) 80 g of the crude product of uliplast acetate was concentrated and dried with 120 g of silica gel, and then passed through 2400 g of silica gel (200-300 mesh silica gel, 30 times the amount by weight), eluted with dichloromethane: acetone = 10: 1, and collected The product was concentrated to dryness to obtain 70g of the desired product.

[0020] 2) After concentrating to dryness, 70 g of uliplast acetate was dissolved in 210 ml of ethyl acetate, 210 ml of petroleum ether was added, and stirred for one hour. Then filter. The solid was washed twice with 100 ml of petroleum ether:ethyl acetate=1:1 mixed solution. Dry under reduced pressure. 58 g of white solid powder were obtained.

[0021] 3) Dissolve 58 grams of white solid powder in 500ml of absolute ethanol, add 500ml of water under reflux under controlled temperature (70~75°C), and let stand to cool down to room temperature. The crystals were filtered and dried under reduced pressure at 40°C to obtain 52 g of ...

Embodiment 3

[0023] 1) Concentrate 60 g of the crude product of Uliplast Acetate with 100 g of silica gel (1.5 times) to dry and load the sample, pass through 900 g of silica gel (200-300 mesh silica gel), elute with dichloromethane: acetone = 15: 1, and collect the product , and concentrated to dryness to obtain 52g of the desired product.

[0024] 2) After concentrating to dryness, 52 g of uliplast acetate was dissolved in 156 ml of ethyl acetate, 780 ml of petroleum ether was added, and stirred for one and a half hours. Then filter. The solid was washed twice with 60 ml of a mixed solution of petroleum ether:ethyl acetate=5:1. Dry under reduced pressure. 49 g of white solid powder were obtained.

[0025] 3) Dissolve 49 grams of white solid powder in 300ml of absolute ethanol, add 450ml of water under reflux conditions under controlled temperature (70~75°C), and let stand to cool down to room temperature. The crystals were filtered and dried under reduced pressure at 40°C to obtain 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com