Method for preparing daptomycin by fermentation

A technology of daptomycin and fermentation method, which is applied in the field of artificial mutagenesis of high-yield strains of daptomycin to produce daptomycin, which can solve the problems of long fermentation period, low unit yield, and low conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

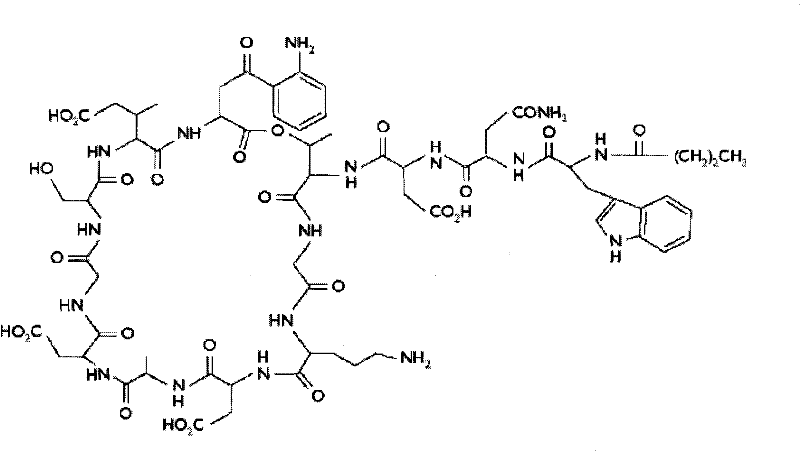

Image

Examples

Embodiment 1

[0030] (1) Seed cultivation

[0031] Primary seed medium: 2.0% trypsin soybean broth, 2.0% dextrin, supplemented with deionized water, pH 6.0.

[0032] Secondary seed medium: soybean powder 0.4%, yeast extract 0.4%, calcium gluconate 0.8%, KCl 0.01%, MgSO 4 ·7H 2 O 0.01%, FeSO 4 ·7H 2 O 0.0003%, Sag 471 (organic silicon defoamer) 0.02%, supplemented with deionized water, the pH value is 6.0.

[0033] Culture conditions: After recovery, the strains were directly inoculated into a 250mL Erlenmeyer flask containing 50mL of primary seed medium, and cultured on a shaker at 30°C at 250rpm for 48h. Take 10 mL of primary seed medium, inoculate it into a 500 mL Erlenmeyer flask with 250 mL of secondary seed medium, and incubate at 250 rpm at 30°C for 24 hours.

[0034] (2) Fermentation culture

[0035] Fermentation medium: glucose 0.85%, CaCO 3 0.3%, soybean flour 3.0%, yeast extract 0.15%, Fe(NH 4 ) 2 SO 4 ·6H 2 O 0.068%, KCl 0.025%, MgSO 4 ·7H 2 O 0.025%, FeSO 4 ·7H 2...

Embodiment 2

[0041] (1) Seed cultivation

[0042] Primary seed medium: 3.0% trypsin soybean broth, 2.5% dextrin, supplemented with deionized water, pH 7.0.

[0043] Secondary seed medium: soybean powder 0.45%, yeast extract 0.5%, calcium gluconate 0.9%, KCl 0.02%, MgSO 4 ·7H 2 O 0.02%, FeSO 4 ·7H 2 O 0.0004%, Sag 471 (organic silicon defoamer) 0.03%, supplemented with deionized water, the pH value is 7.0.

[0044] Culture conditions: After recovery, the strains were directly inoculated into a 250mL Erlenmeyer flask containing 50mL of primary seed medium, and cultured on a shaker at 30°C at 250rpm for 48h. Take 10 mL of primary seed medium, inoculate it into a 500 mL Erlenmeyer flask with 250 mL of secondary seed medium, and incubate at 250 rpm at 30°C for 24 hours.

[0045] (2) Fermentation culture

[0046] Fermentation medium: glucose 0.83%, CaCO 3 0.2%, soybean flour 2.0%, yeast extract 0.1%, Fe(NH 4 ) 2 SO 4 ·6H 2 O 0.066%, KCl 0.02%, MgSO 4 ·7H 2 O 0.02%, FeSO 4 ·7H 2 O...

Embodiment 3

[0052] (1) Seed cultivation

[0053] Primary seed medium: 4.0% trypsin soybean broth, 3.0% dextrin, supplemented with deionized water, pH 8.0.

[0054] Secondary seed medium: soybean powder 0.5%, yeast extract 0.6%, calcium gluconate 1.0%, KCl 0.03%, MgSO 4 ·7H 2 O 0.03%, FeSO 4 ·7H 2 O 0.0005%, Sag 471 (organic silicon defoamer) 0.04%, supplemented with deionized water, the pH value is 8.0.

[0055] Culture conditions: After recovery, the strains were directly inoculated into a 250mL Erlenmeyer flask containing 50mL of primary seed medium, and cultured on a shaker at 30°C at 250rpm for 48h. Take 10 mL of primary seed medium, inoculate it into a 500 mL Erlenmeyer flask with 250 mL of secondary seed medium, and incubate at 250 rpm at 30°C for 24 hours.

[0056] (2) Fermentation culture

[0057] Fermentation medium: glucose 0.80%, CaCO 3 0.1%, soybean flour 1.0%, yeast extract 0.05%, Fe(NH 4 ) 2 SO 4 ·6H 2 O 0.065%, KCl 0.015%, MgSO 4 ·7H 2 O 0.015%, FeSO 4 ·7H 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com