Method for preparing monocrystalline CaTiO3 dendrite

A single crystal and ethanol technology, applied in the directions of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems of difficult preparation and complexity, and achieve the effect of convenient control and simple process route.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1) Dissolve butyl titanate in ethanol, stir until uniform to obtain liquid A, and the molar ratio of butyl titanate and ethanol is 1:10;

[0019] 2) Dissolve calcium chloride dihydrate in distilled water, and mix and stir with ethanol to obtain liquid B. The molar ratio of butyl titanate: calcium chloride dihydrate: water: ethanol is 1:1:400:5;

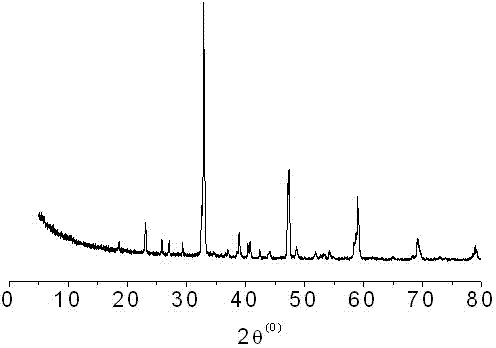

[0020] 3) Add solution A dropwise to solution B, stir for 10min, then gradually add NaOH solution dropwise, adjust the pH value to 10, continue to stir for 15min and mix, put it in a hydrothermal kettle, and keep it at a hydrothermal temperature of 180°C for 36h , washed with distilled water 6 times to obtain CaTiO 3 dendrites. Its X-ray diffraction pattern is figure 1 shown, its diffraction peaks are consistent with the orthogonal CaTiO 3 The standard spectra of the phases are consistent, indicating that the obtained product is orthorhombic CaTiO 3 Mutually.

Embodiment 2

[0022] 1) Dissolve butyl titanate in ethanol, stir until uniform to obtain liquid A, and the molar ratio of butyl titanate and ethanol is 1:6;

[0023] 2) Dissolve calcium chloride dihydrate in distilled water, and mix and stir with ethanol to obtain liquid B. The molar ratio of butyl titanate: calcium chloride dihydrate: water: ethanol is 1:1:400:5;

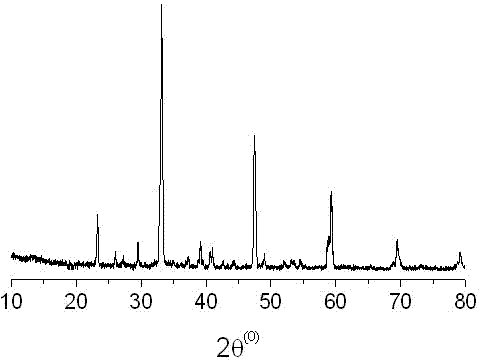

[0024] 3) Add liquid A into liquid B dropwise, stir for 5 minutes, then gradually add NaOH solution dropwise, adjust the pH value to 10, continue to stir for 15 minutes and mix, put it in a hydrothermal kettle, and keep it at a hydrothermal temperature of 200 ° C for 24 hours . Washed with distilled water for 3 times to obtain CaTiO 3 dendrites. Its X-ray diffraction pattern is figure 2 shown, its diffraction peaks are consistent with the orthogonal CaTiO 3 The standard spectra of the phases are consistent, indicating that the obtained product is orthorhombic CaTiO 3 Mutually.

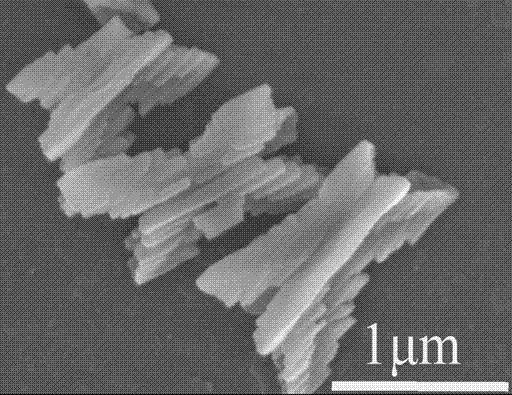

[0025] CaTiO prepared in this example 3 El...

Embodiment 3

[0027] 1) Dissolve butyl titanate in ethanol, stir until uniform to obtain liquid A, and the molar ratio of butyl titanate and ethanol is 1:6;

[0028] 2) Dissolve calcium chloride dihydrate in water, mix and stir with ethanol to obtain liquid B, butyl titanate: dihydrate

[0029] The molar ratio of calcium chloride: water: ethanol is 1:1:20:9;

[0030] 3) Add solution A dropwise to solution B, stir for 8min, then gradually add NaOH solution dropwise, adjust the pH value to 10, continue to stir for 15min and mix, put it in a hydrothermal kettle, and keep it at a hydrothermal temperature of 260°C for 18h , washed with distilled water 6 times to obtain CaTiO 3 dendrites.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com