Current detection circuit

A current detection circuit and current technology, applied in the direction of circuit, measuring current/voltage, only measuring current, etc., can solve problems such as low withstand voltage, and achieve the effect of high-precision detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

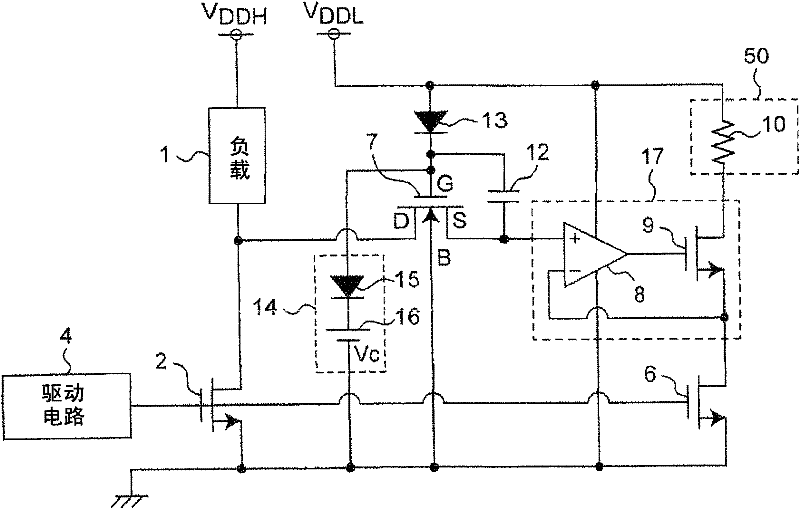

[0039] figure 1 It is a circuit diagram of the current detection circuit of the first embodiment of the present invention. in figure 1 In this embodiment, the current detection circuit of this embodiment is configured as an integrated circuit, and includes a load 1, a power transistor 2, a detection transistor 6, a voltage control circuit 17 including an operational amplifier 8 and an output transistor 9, a detection circuit 50 including a resistor 10, and a protection A MOSFET 7, a diode 13, an electrostatic capacitor 12, a clamping circuit 14 including a diode 15 and a DC voltage source 16, and a driving circuit 4 are used.

[0040] As described in detail later, the current detection circuit of this embodiment is characterized by having:

[0041] (a) The power transistor 2 has a source, a drain, and a gate, and controls the current flowing between the drain and the source by a control voltage applied to the gate;

[0042] (b) The detection transistor 6, which has a source, a dra...

no. 2 approach

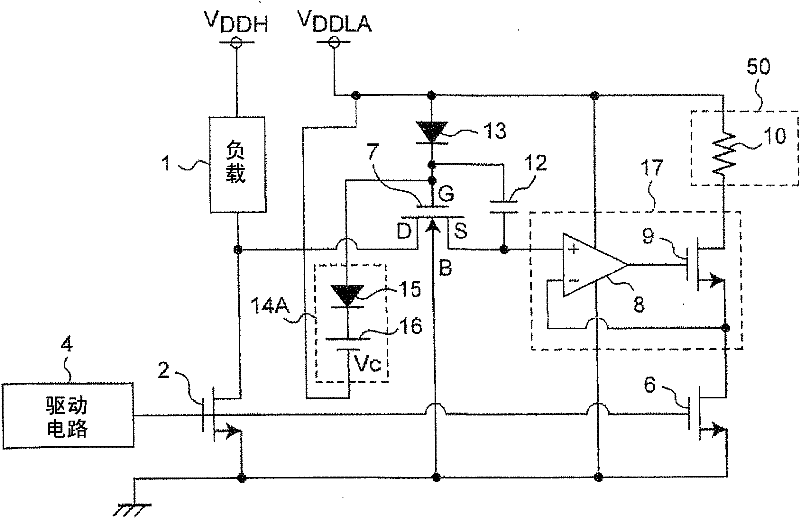

[0076] Figure 7 It is a circuit diagram of the current detection circuit of the second embodiment of the present invention. Compared with the first embodiment, this embodiment is different in that a load 1 is connected between the source of the power transistor 2 and the ground potential. In addition, the connection point between the drain of the power transistor 2 and the protection MOSFET 7 does not pass through the load 1, but is directly connected to the output power supply voltage V DDH Voltage source. in Figure 7 When the power transistor 2 is turned on by the drive circuit 4, the drain current flows through the power transistor 2 as in the first embodiment, and the resistance component of the power transistor 2 when it is turned on is more exciting than when it is not turned on. Drain voltage with low drain voltage. In addition, the voltage between the source and the drain of the power transistor 2 decreases, the potential difference between the drain and the gate of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com