Intra-cavity frequency doubling green-ray fiber laser with full optical fiber structure

A fiber laser and intracavity frequency doubling technology, applied in the laser field, can solve the problems of not meeting the needs of technological development, the high stability of the fiber laser is destroyed, and the advantages of the fiber laser cannot be displayed, and the output of the high-power laser can be achieved. , compact structure, low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

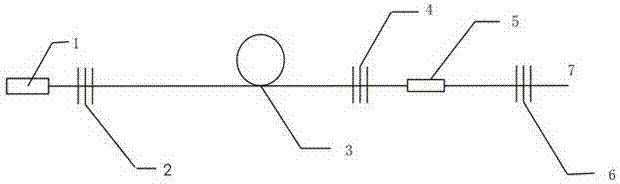

[0034] Such as figure 1 As shown, the intracavity frequency-doubled green fiber laser of the all-fiber structure of the present invention includes a pump assembly 1, a first fiber grating 2, a third fiber grating 4, a second fiber grating 6 and a first pigtail 7, and the pump The output end of the Pu assembly 1 is connected to the first fiber Bragg grating 2, a double-clad ytterbium-doped fiber 3 is connected between the first fiber Bragg grating 2 and the third fiber Bragg grating 4, and the third fiber Bragg grating 4 and the second fiber Bragg grating 6 are connected to each other. There is an intracavity frequency multiplier 5, the output end of the second fiber grating 6 is connected to the first pigtail 7, and the above-mentioned components are connected by welding.

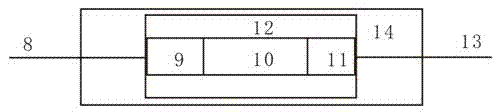

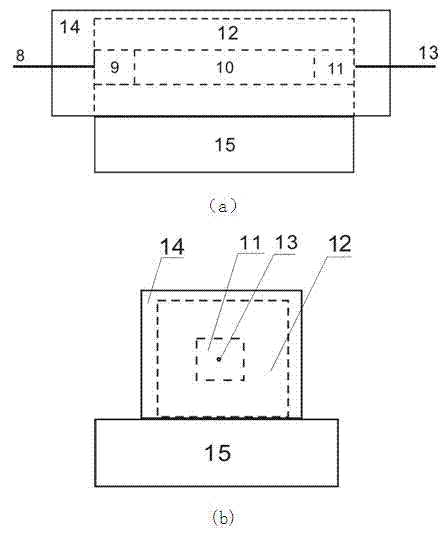

[0035] Such as figure 2 , image 3As shown, the intracavity frequency doubler 5 includes a first self-focusing lens 9, a frequency doubling crystal 10, a second self-focusing lens 11, a second pigtail 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com