Dehydration method for desorption gas used in desulphurization of flue gas

A desorption and gas technology, applied in separation methods, chemical instruments and methods, sulfur compounds, etc., can solve the problems of dilution of desulfurization solution, reduction of energy consumption for desorption, and increase of energy consumption for desulfurization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

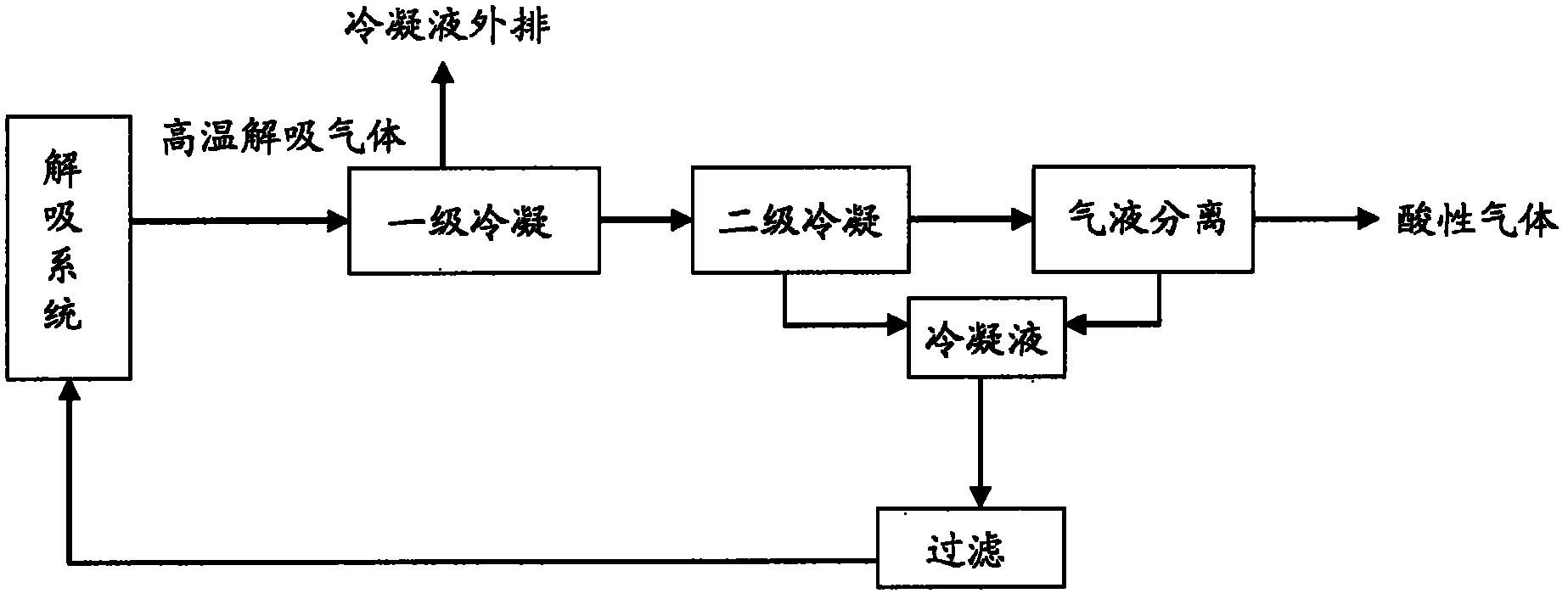

[0026] refer to figure 1 , In this embodiment, the high-temperature desorption gas desorbed from the desorption system is subjected to two-stage condensation. The first condensate produced by the primary condensation is directly discharged, and the first condensate mainly contains water and a small amount of sulfurous acid. Then the desorption gas mainly containing desulfurizing agent, water and impurities produced by the primary condensation is subjected to secondary condensation to produce a second condensate and desorption gas. The second condensate is a saturated sulfurous acid solution and contains a small amount of desulfurizing agent and impurities ( Such as sulfur, etc.).

[0027] Subsequently, the desorbed gas is supplied to a gas-liquid separation device for gas-liquid separation, thereby generating sulfur dioxide-containing acid gas and liquid. The liquid produced by gas-liquid separation mainly contains water, and contains a large amount of sulfur dioxide and imp...

Embodiment 2

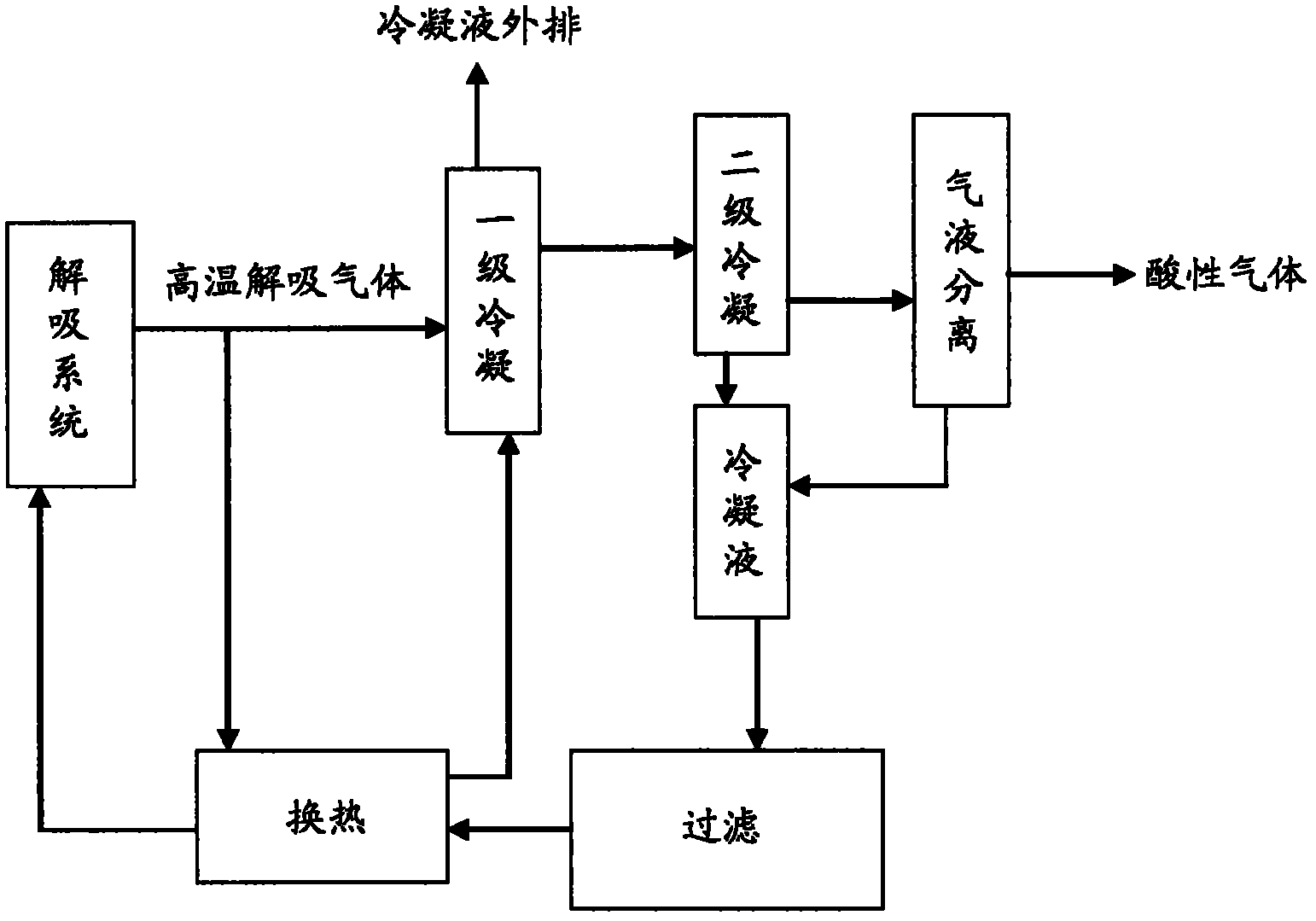

[0031] refer to figure 2 , in this embodiment, in addition to including the steps in Embodiment 1, the method of this embodiment also includes the following steps: before providing the filtered desulfurization liquid into the desorption system, making the desulfurization solution The thermal system exchanges heat with a part of the desorbed gas desorbed from the desorption system, then supplies the desulfurization solution after heat exchange to the desorption system, and makes the part of the desorbed gas after heat exchange go through steps such as primary condensation.

Embodiment 3

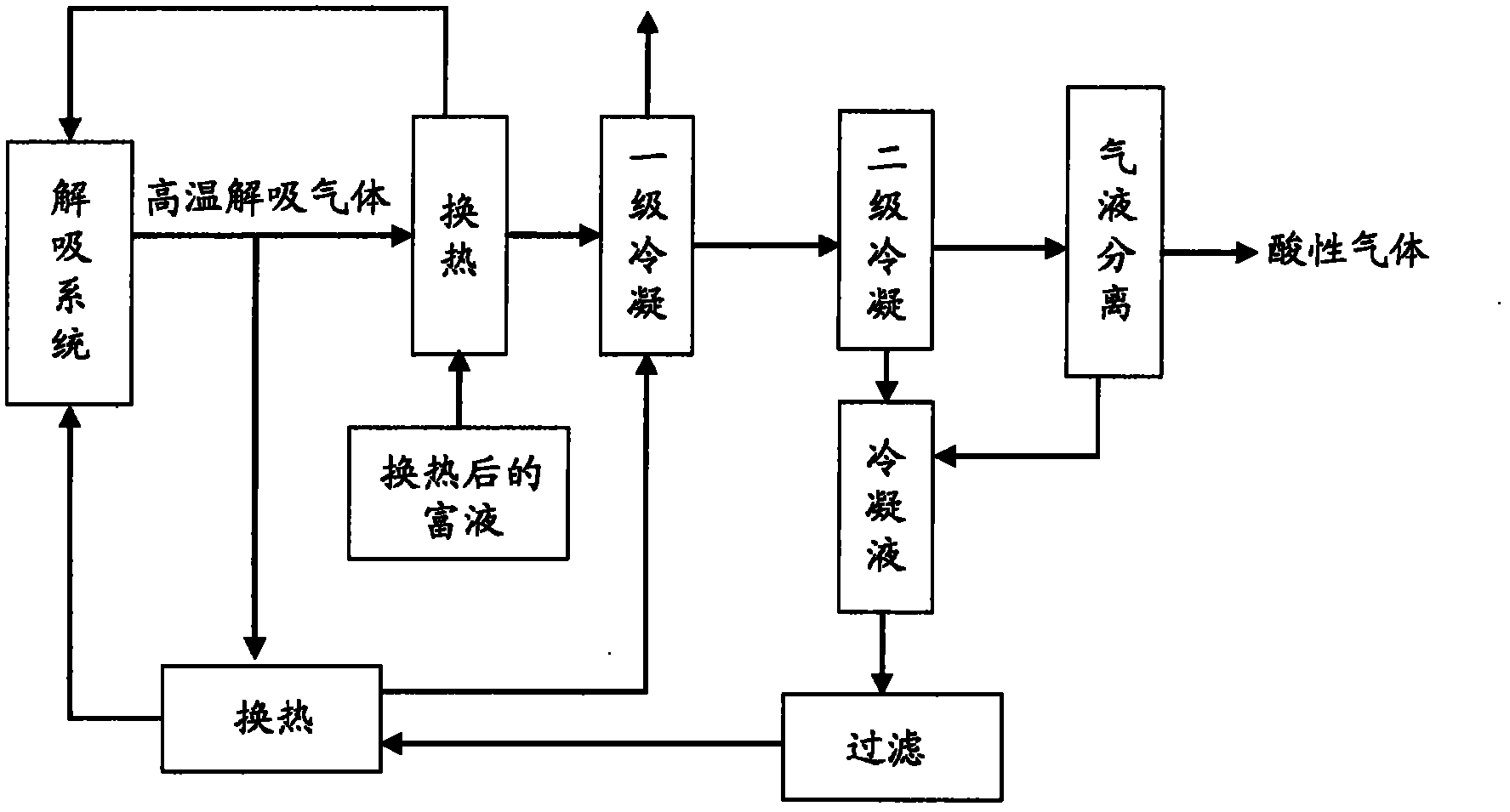

[0033] refer to image 3 , in this embodiment, in addition to including the steps in Embodiment 2, the method of this embodiment also includes the following steps: make another part of the desorbed gas desorbed from the desorption system exchange heat with the second heat exchange system After heat exchange, the rich liquid after heat exchange is then supplied to the desorption system, and the other part of the desorbed gas after heat exchange is subjected to steps such as primary condensation. In this embodiment, the rich liquid after heat exchange is the rich liquid that has absorbed sulfur dioxide after heat exchange with the high-temperature lean liquid from the desorption system from the absorption tower. Specifically, the temperature of the rich liquid that has absorbed sulfur dioxide in the absorption tower is 45-55°C, and the temperature of the high-temperature lean liquid discharged from the bottom of the desorption system is 100-115°C. After the heat exchange of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com