Perovskite-like catalyst used for purifying automobile tail gas, and preparation method thereof

A technology for automobile exhaust gas and catalyst, which is applied in chemical instruments and methods, separation methods, dispersed particle separation and other directions, can solve the problems of unsuitable purification of automobile exhaust gas and low activity, and achieves the effects of low cost, simple operation and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Weigh 9.1g lanthanum nitrate (La(NO 3 ) 3 ·6H 2 O), 1.1g strontium nitrate (Sr(NO 3 ) 2 ), 3.8g nickel nitrate (Ni(NO 3 ) 3 ·6H 2 O), 2.5g citric acid (C 6 h 8 o 7 ·H 2 (0), it was dissolved in 100ml deionized water, stirred and dissolved at a temperature of 50° C. for half an hour; the mixed solution was heated at a temperature of 110° C., and the water was evaporated to obtain a catalyst precursor; Pre-calcining the catalyst precursor in a muffle furnace at a heating rate of ℃ / min, the temperature was raised to 400°C, kept at a constant temperature for 3 hours, and weighed to obtain 6.5g of the catalyst precursor after cooling; the pre-calcined catalyst precursor was mixed with Add 0.2 g of ground activated carbon powder, and press it into tablets with a pressure of 9 MPa; under the protection of nitrogen, calcinate the catalyst precursor after the tablet molding at a heating rate of 10 °C / min, and the temperature rises to 1100 ℃, constant temperature for 3...

Embodiment 2

[0022] Weigh 9.1g lanthanum nitrate (La(NO 3 ) 3 ·6H 2 O), 1.1g strontium nitrate (Sr(NO 3 ) 2 ), 3.8g nickel nitrate (Ni(NO 3 ) 3 ·6H 2 O), 2.9g citric acid (C 6 h 8 o 7 ·H 2 O), it was dissolved in 90ml deionized water, stirred and dissolved at a temperature of 50°C for half an hour; the mixed solution was heated at a temperature of 100°C, and the water was evaporated to obtain a catalyst precursor; The catalyst precursor was pre-calcined at a heating rate of / min, and the temperature was raised to 450°C, kept at a constant temperature for 2.5 hours, and weighed after cooling to obtain 6.2g of the catalyst precursor; 0.3g of Printex-U was added to the pre-calcined catalyst precursor Type carbon black, with a pressure of 10MPa, it is tableted; under the protection of nitrogen, the catalyst precursor after tableting is calcined at a heating rate of 10°C / min, and the temperature rises to 900°C, and the temperature is maintained for 4 hours. The catalyst was obtained ...

Embodiment 3

[0025] Weigh 9.1g lanthanum nitrate (La(NO 3 ) 3 ·6H 2 O), 1.1g strontium nitrate (Sr(NO 3 ) 2 ), 3.8g nickel nitrate (Ni(NO 3 ) 3 ·6H 2 O), 2g citric acid (C 6 h 8 o 7 ·H 2 O), it was dissolved in 100ml deionized water, stirred and dissolved at a temperature of 50°C for half an hour; the mixed solution was heated at a temperature of 100°C, and the water was evaporated to dryness to obtain a catalyst precursor; The catalyst precursor was pre-calcined at a heating rate of ℃ / min. The temperature was raised to 410°C, kept at a constant temperature for 3.5 hours, and weighed to obtain 7.3g of the catalyst precursor after cooling; The final activated carbon powder was pressed into tablets with a pressure of 10MPa; under the protection of nitrogen, the catalyst precursor was calcined at a heating rate of 9°C / min, and the temperature was raised to 1200°C and kept at a constant temperature for 4 hours. , and the catalyst was obtained after cooling.

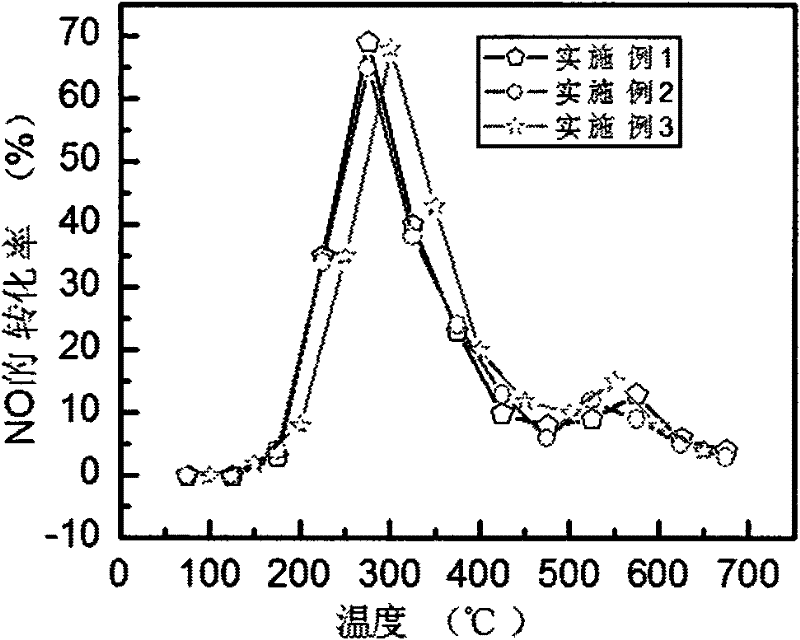

[0026] Activity evalua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com