Rotary adjustable water waveguide laser processing device

A laser processing and waveguide technology, applied in the field of rotary adjustable water waveguide laser processing devices, can solve problems such as low efficiency, small processing range, and insufficient processing flexibility, and achieve easy system, good adjustability, and high coupling processing accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

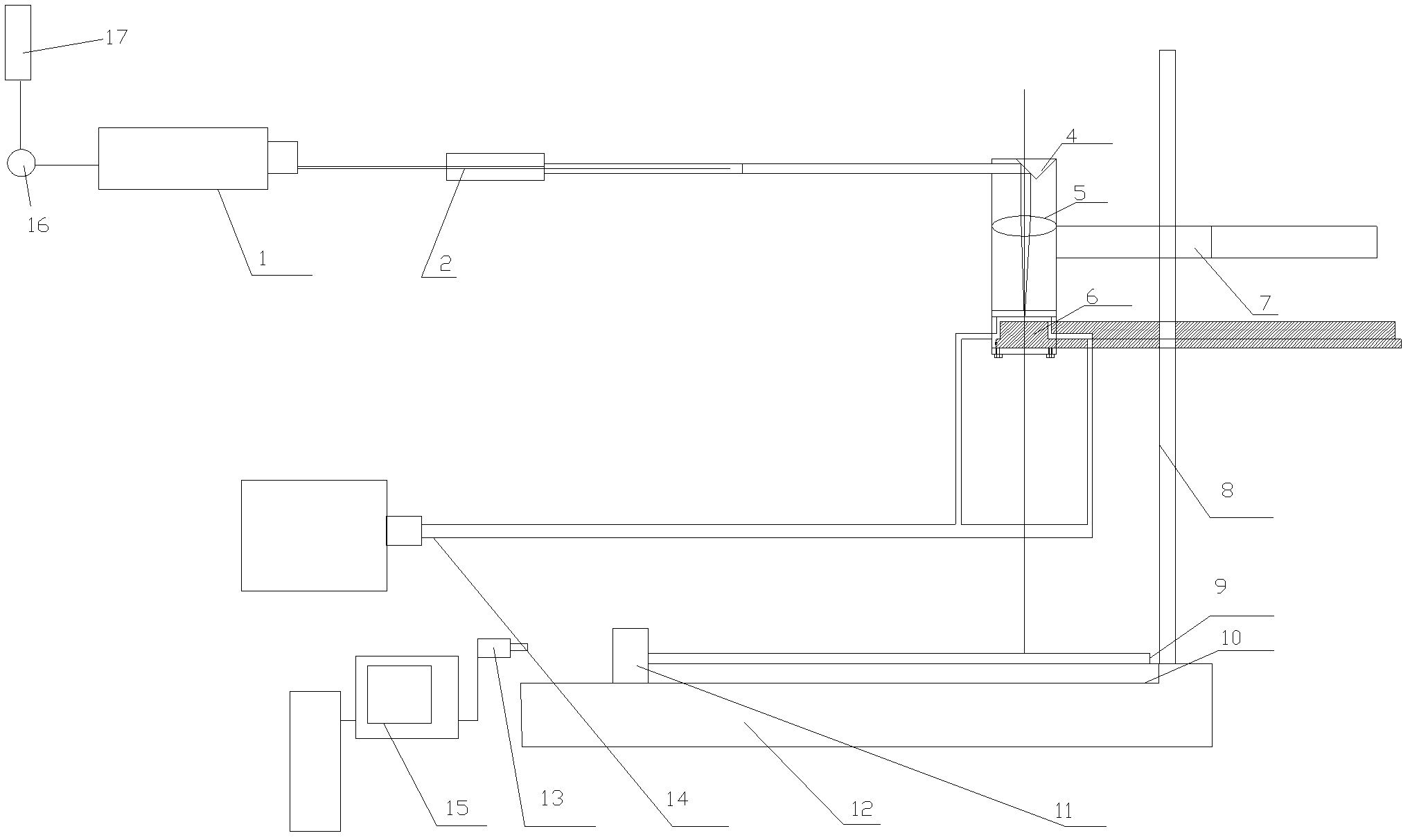

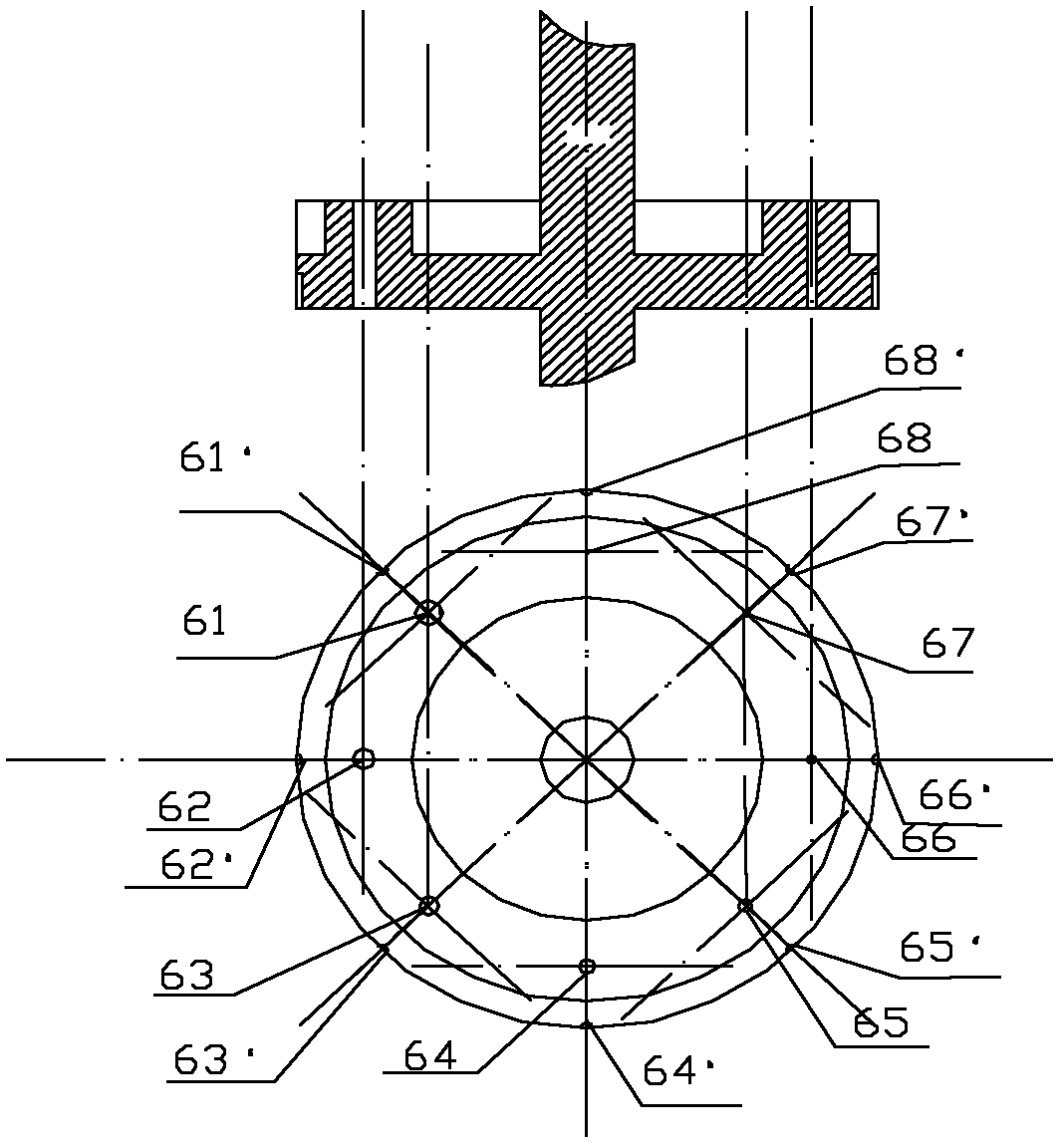

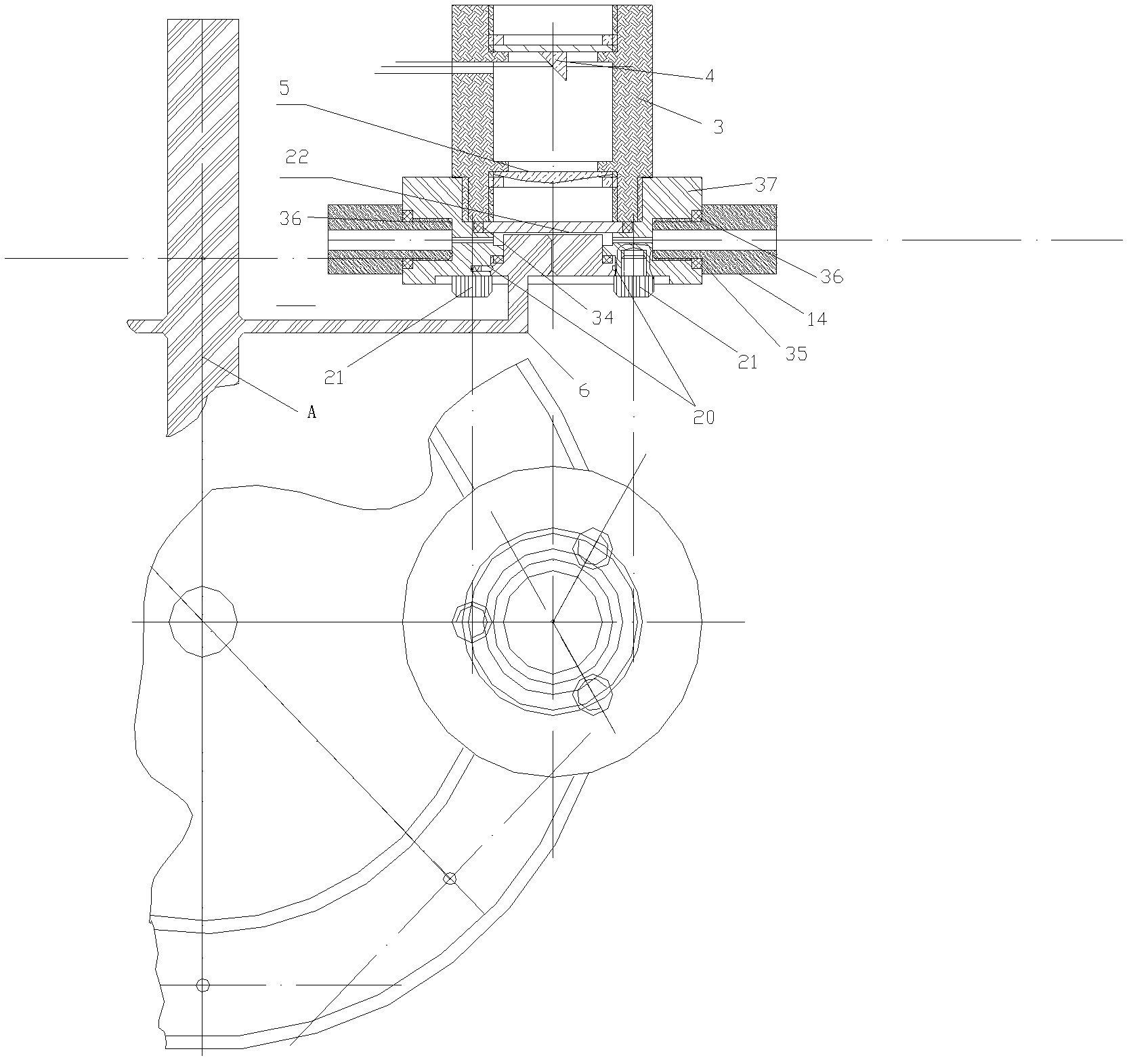

[0024] see Figure 1~3 , the embodiment of the present invention is provided with laser device 1, inverted telescope 2, lens barrel 3, first reflector 4, focusing lens 5, nozzle body 6, nozzle holder 7, bracket 8, workpiece to be processed 9, water collector 10, Fixture 11, CNC platform 12, camera 13, water circulation device 14, data acquisition and processing and control computer 15, observation laser (collimated helium-neon laser) 16, second reflector 17, positioning tenon 20, compression screw 21 , flat glass 22, sealing ring 34, sealing ring 35, sealing ring 36, water cavity 37, a series of nozzle arrays 61, 62, 63 from large to small, taking 8 as an example, on the nozzle body 6, 64 , 65 , 66 , 67 , 68 , bayonet arrays 61 ′, 62 ′, 63 ′, 64 ′, 65 ′, 66 ′, 67 ′, 68 ′ of nozzles at corresponding positions on the outer edge of the nozzle body 6 .

[0025] The inverted telescope 2 used to expand and collimate the processing laser beam is installed directly in front of the la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com