Silicon-cup energy-accumulation Al/CuO composite film ignition bridge and ignition bridge array

A composite film and ignition bridge technology, applied in fuzes, offensive equipment, etc., can solve problems such as low energy conversion rate, and achieve the effect of enhancing ignition capability, improving radio frequency resistance, and improving integration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

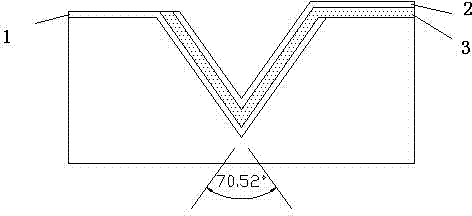

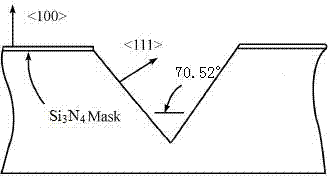

[0040] A Single Silicon Cup Gathering Al / CuO Composite Thin Film Ignition Bridge

[0041] Fabrication of Si on a 100-sided silicon substrate 3 N 4 Mask, using silicon anisotropic etching technology to etch out such as figure 2 The silicon cup shown in the square pyramid structure has a side length of 1 mm. Corrosion conditions are: 5% mass concentration of TMAH (tetramethylammonium hydroxide) corrosion solution, corrosion temperature 85 ° C, when the predetermined depth is reached, use 20% TMAH solution + 1% AP (ammonium perchlorate) , the temperature is 85°C, and the time is half an hour to modify and reduce the roughness.

[0042] The process of the ignition bridge is as follows: the substrate is ultrasonically cleaned with acetone and deionized water for 30 minutes, dried in the air, and then baked in an oven at 200°C for later use. Use a positive reversal photoresist (AZ5200) to coat the substrate and then dry it. After adding the mask of the underlying metal thin fil...

Embodiment 2

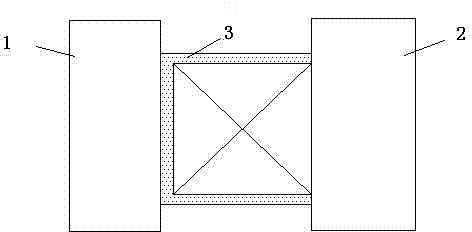

[0045] Ignition Array Based on Silicon Cup Concentrated Al / CuO Composite Thin Film Ignition Bridge

[0046] Silicon cup energy-gathering Al / CuO composite film ignition bridge arrays are all made by microfabrication technology, and micro ignition arrays can be fabricated on the basis of the single ignition bridge described in Example 1. The structure of the firing array is as Figure 5 shown.

[0047] Figure 5 The middle black part is the ignition bridge, which constitutes 6×6 ignition units, and the independent ignition of the ignition units can be realized through the ignition bus and the logical addressing circuit of the unit. The logic addressing circuit material adopts Cu or Au thin film, and Cu or Au thin film has lower resistivity, and has less influence on the ignition bridge, and the width of the line is 50 μm. The logic addressing ignition circuit similar to this kind can be used for the ignition of the micro-thrust system, and can also be used for the multi-point...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com