Method for preparing polymer crystal at low temperature by using ultraviolet polymerization

A UV and polymer technology, applied in the direction of ester copolymer adhesives, adhesive types, coatings, etc., can solve the problems without further research on the microscopic morphology of the photopolymerization system, and achieve the goal of broadening the temperature range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

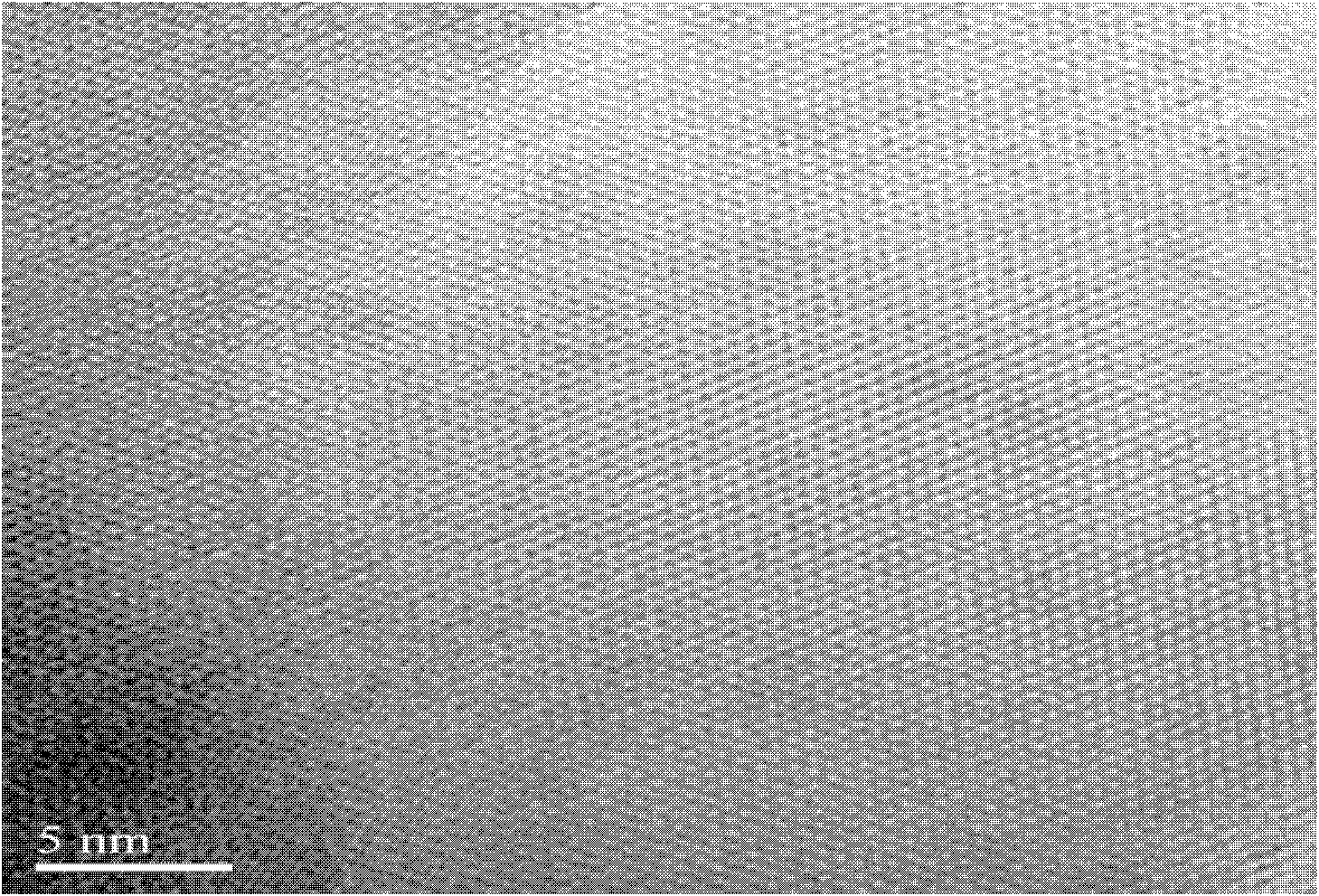

[0023] Take 0.03g of photoinitiator 1173 and add it to 6.00g of HDDA to prepare a photopolymerization system with a mass ratio of initiator to monomer of 1:200. Ultrasonic vibration at room temperature for 5 minutes makes the system uniformly dispersed. Inject the system into the mold with a 1mL needle tube, put it into a low-temperature constant temperature tank, and keep the temperature at -25°C, and use 30mW / cm 2 The ultraviolet light irradiates the polymerization system for 1min, and the polymerized sample is soaked in acetone for 48h. After the treatment, the sample is prepared and the crystal structure can be observed under the high-resolution transmission electron microscope. The interplanar distance d=0.2857nm. In cold climates in winter, low-temperature curing light-curing materials can be applied to coatings at low temperatures.

Embodiment 2

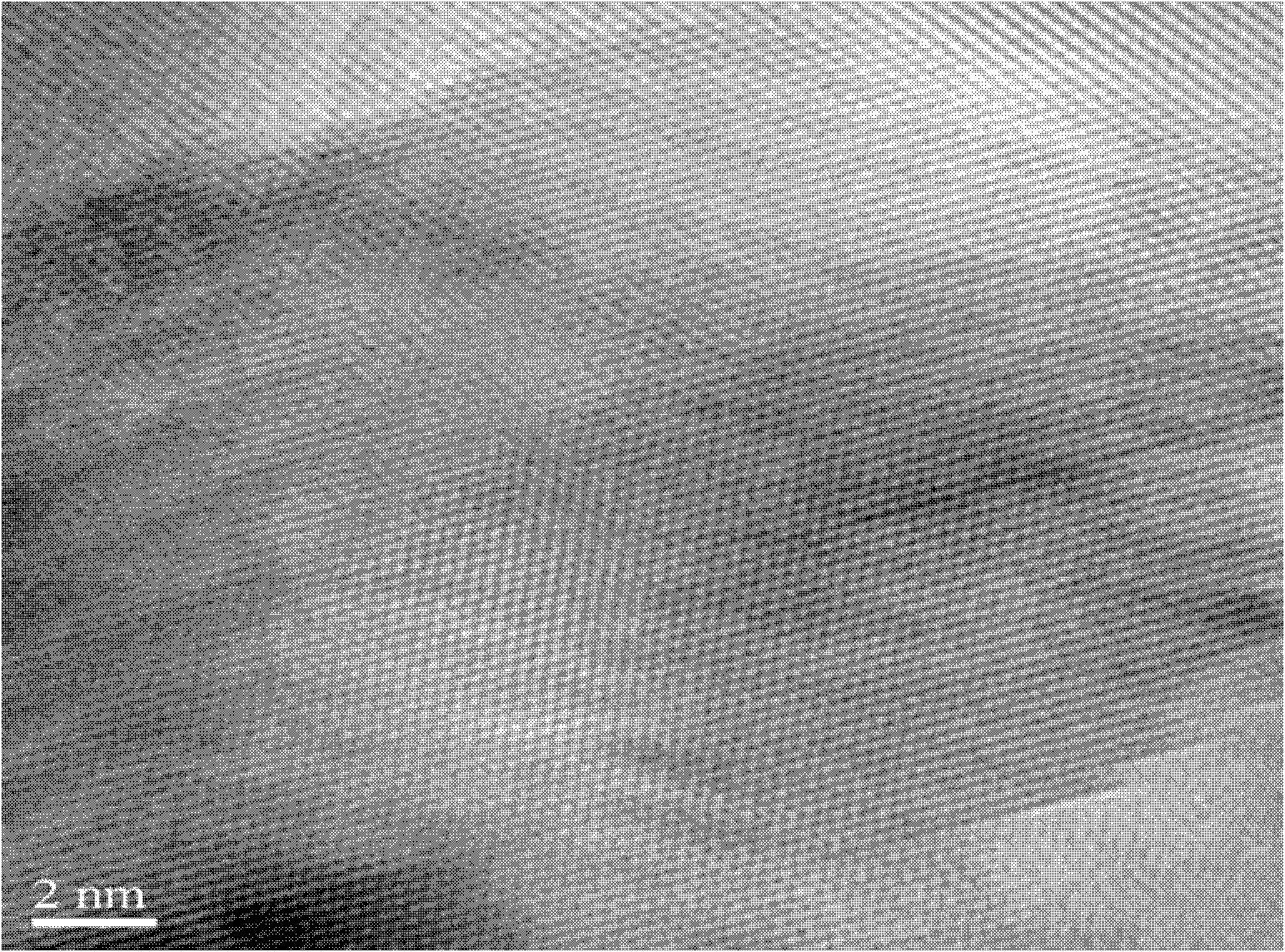

[0025] Take 0.003g of photoinitiator 184, add it to 6.00g of HDDA, and prepare six sets of photopolymerization systems with a mass ratio of initiator to monomer of 1:200, numbered (1) to (6), and ultrasonically shake at room temperature for 100 minutes. Mix the system evenly. The system was injected into the mold with a 1 mL needle. Put the polymerization systems numbered (1), (2) and (3) into a low-temperature thermostat, and drop the temperature from room temperature to -25 °C, -10 °C and 0 °C at a rate of 1.6 °C / min, respectively. 80mW / cm 2 The ultraviolet light was irradiated on the polymerization system for 50min. Put the polymerization systems numbered (4), (5) and (6) into the low-temperature constant temperature baths whose temperature has been stabilized at -25°C, -10°C and 0°C respectively, and use a light intensity of 80mW / cm 2 The ultraviolet light was irradiated on the polymerization system for 50min. Put the polymerized samples (1) to (6) into acetone and soa...

Embodiment 3

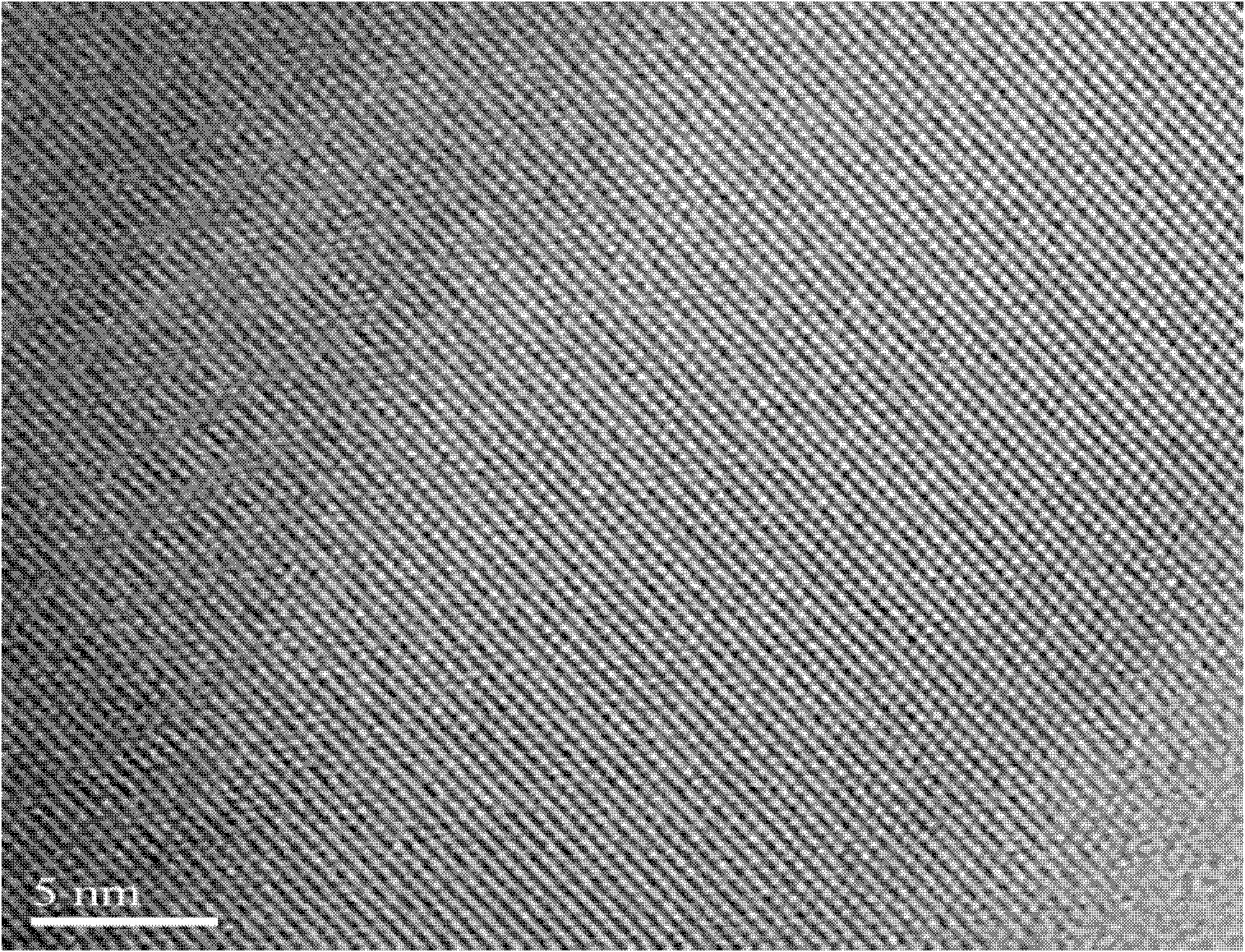

[0027] Take 0.300g of photoinitiator 819 and add it to 6.00g of HDDA to prepare a photopolymerization system with a mass ratio of initiator to monomer of 1:20. Ultrasonic vibration at room temperature for 15 minutes makes the system uniformly dispersed. Inject the system into the mold with a 1mL needle tube, place it in a low-temperature constant temperature bath, keep the temperature at -30°C, and use a light intensity of 45mW / cm 2 The system was irradiated with ultraviolet light for 15 minutes to obtain polymer crystals. Its interplanar spacing d=0.3458nm can be used as a low-temperature adhesive material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| lattice spacing | aaaaa | aaaaa |

| lattice spacing | aaaaa | aaaaa |

| lattice spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com