Multifunctional intermittent expansion solid-state fermentation tank

A solid-state fermenter and multi-functional technology, applied in the field of fermenter, can solve the problems of low charging rate, complex internal structure, inconvenient maintenance, etc., and achieve the effect of fast drying, low labor intensity and high charging rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

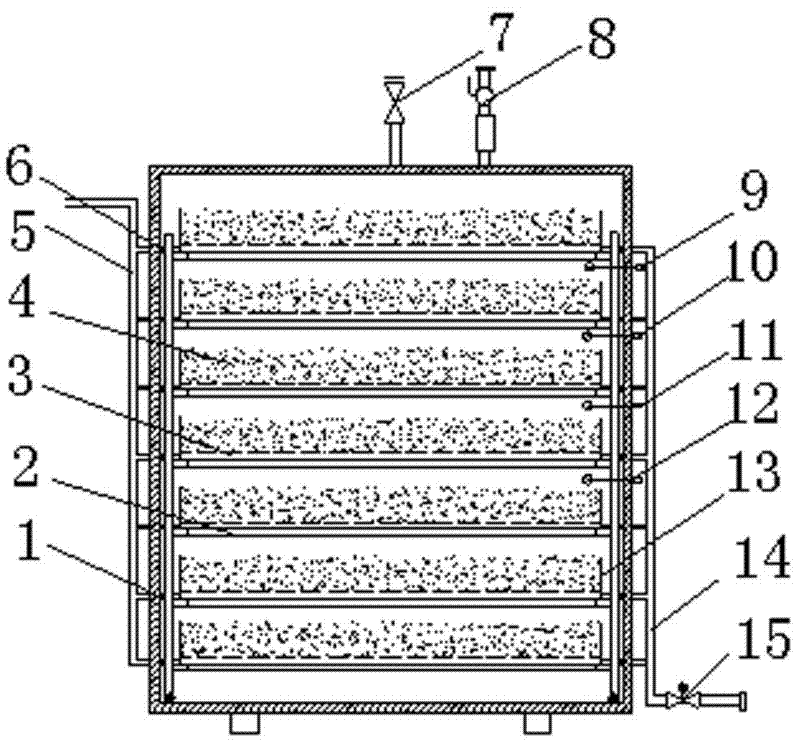

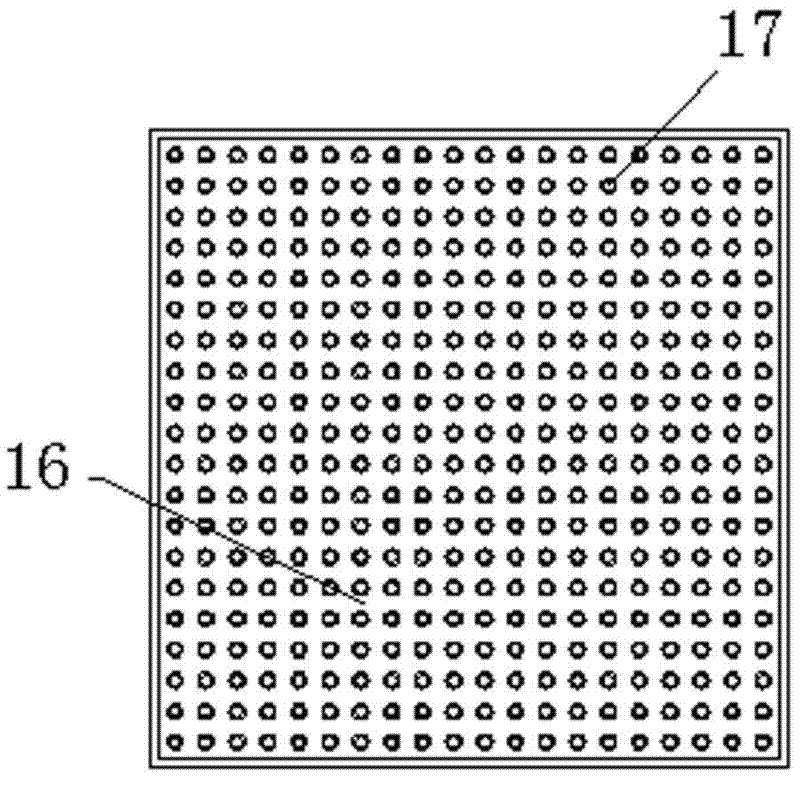

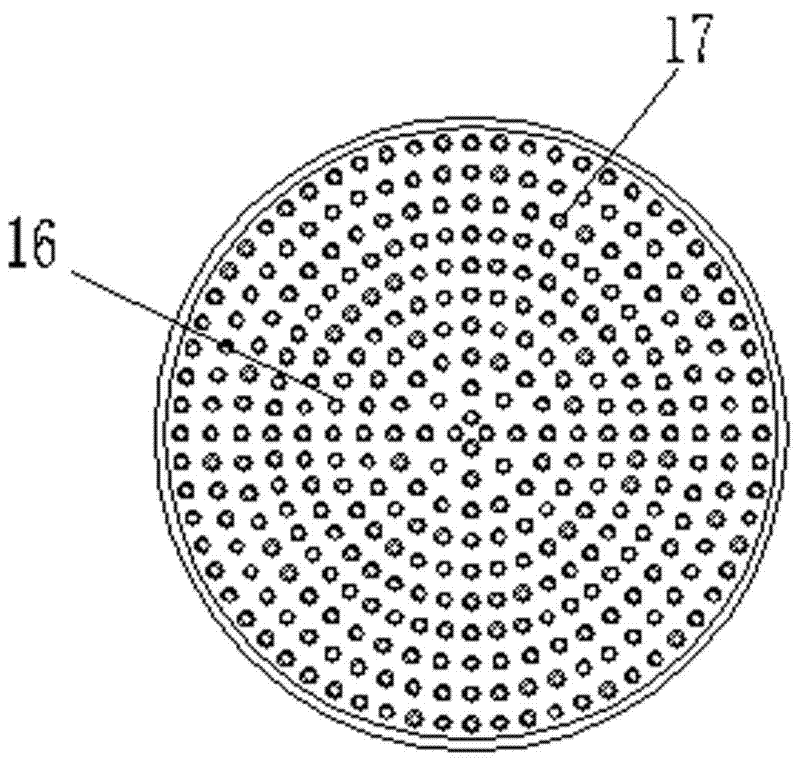

[0021] With reference to accompanying drawing: be equipped with vent safety valve 7, the exhaust pipe 8 with air filter, thermometer 9, pH probe 10, moisture probe 11, dissolved oxygen probe 12 on fermentation tank body 1; There is a gas distribution and liquid distribution main pipe 5 and a liquid discharge main pipe 14 composed of a liquid pipeline, a steam pipeline and a gas pipeline, and a liquid discharge main valve 15 is provided at the bottom of the tank. There is also a loading vehicle that can be pushed into the tank through the sealed door on the tank wall; there are 6-30 layers of loading vehicles; each layer is 10-35cm high; The base plate 3 for holding the solid medium, the base plate 3 is composed of two parallel metal plates, and the outer wall of the base plate is 7-30 cm high. On the top base plate 16, there is a hole 17 as the outlet of inoculation liquid and heat transfer and oxygen supply gas; on the bottom base plate 23, there is a diversion groove 20 for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com